Notching forming device for bag making machine

A forming device and bag making machine technology, which is applied in the direction of bag making, packaging, transportation and packaging, etc., can solve the problems affecting the forming and packing of bags, pushing out waste materials, sorting and folding bags, etc., so as to facilitate sorting and packing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

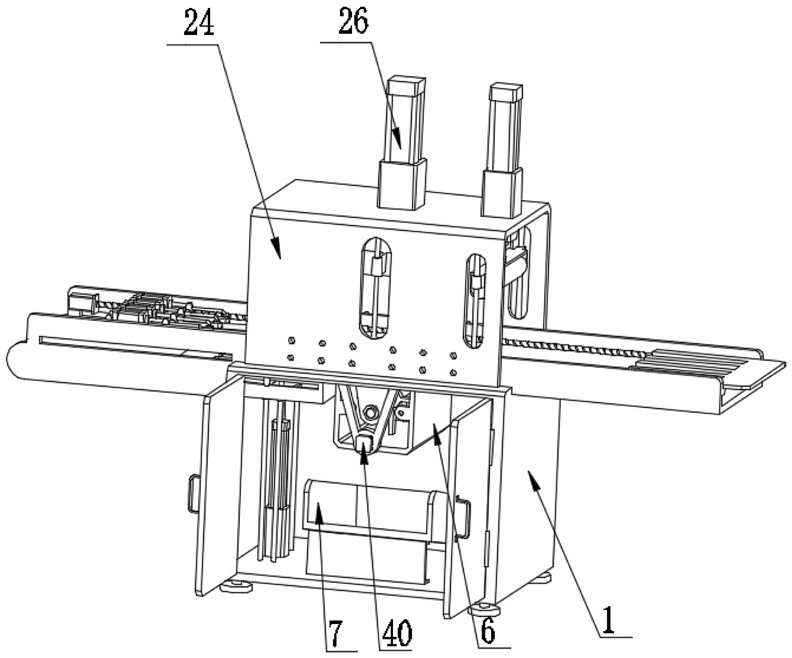

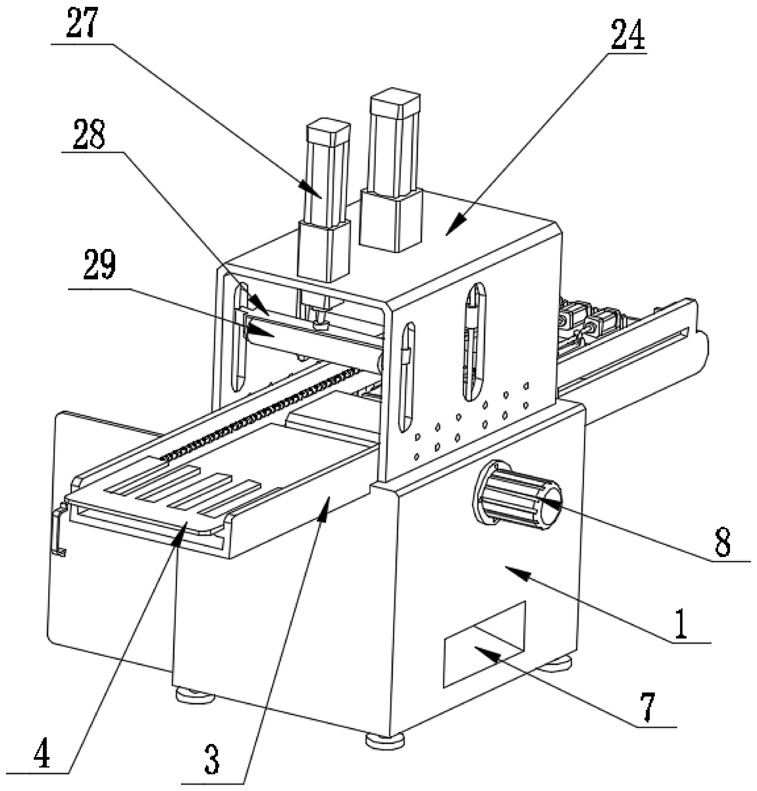

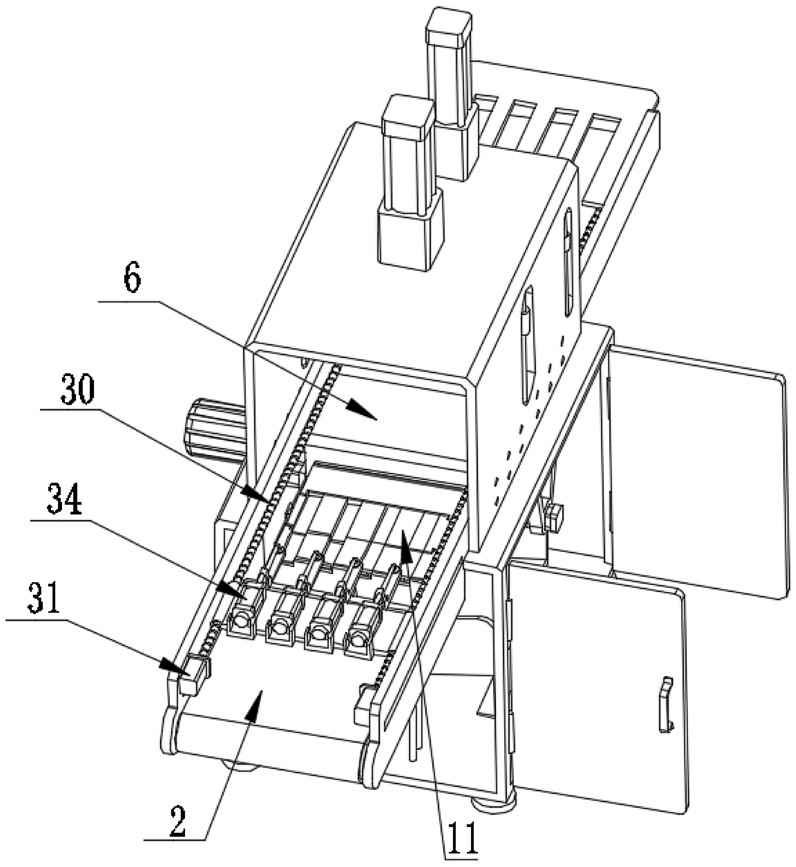

[0039] A kind of notch forming device for bag making machine of this embodiment, refer to Figure 1-10 : including a body 1, a conveyor belt 2 arranged on the left side of the top of the body 1, a conveying trough 3 arranged on the right side of the top of the body 1, a grid plate 4 arranged in the end of the conveying trough 3, and a conveyor belt arranged on the top of the body 1 The punching mechanism and the material shifting mechanism arranged above the top of the body 1, the upper part of the body 1 is connected with a rectangular punching frame 6 through the rotation of the shaft 5, the lower part of the body 1 is tilted backward to set up a waste chute 7, and the rear side of the upper part of the body 1 The wall is provided with a stepper motor 8 that drives the shaft 5 to rotate, and a lifting cylinder 9 is provided in the lower side of the left part of the body 1, and a folding mechanism is provided at the output shaft end of the lifting cylinder 9;

[0040] The rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com