Large-diameter radian bending method of steel pipe and large-bend pipe bender

A large-radius, steel pipe technology, applied in the field of pipe bending methods and devices, can solve the problems of inconvenient operation, large floor space, and inability to implement a cold bending pipe bending machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

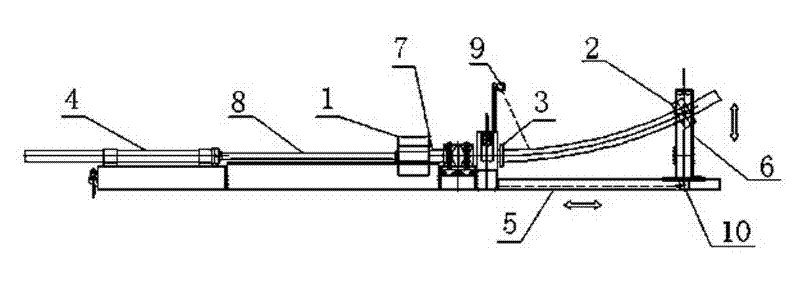

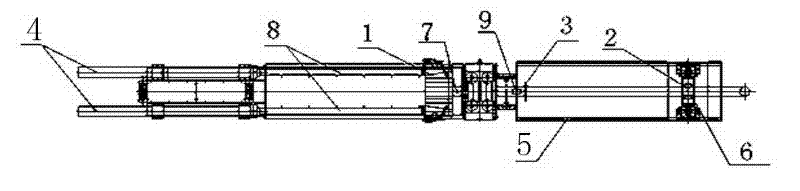

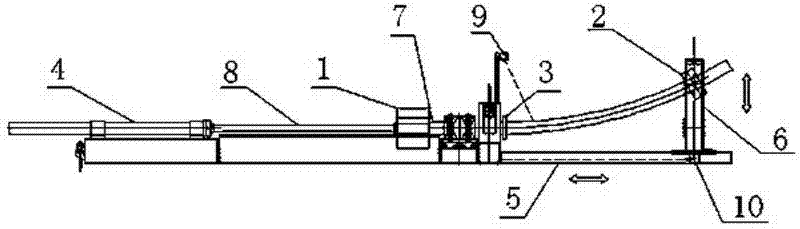

[0013] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the description of the embodiments. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention. For Those of ordinary skill in the art can also obtain other drawings based on these drawings without making creative efforts.

[0014] A method for bending a steel pipe with a large-radius arc, using a propulsion oil cylinder to push a steel pipe clamping device to move horizontally, the steel pipe clamping device clamps one end of the steel pipe, a positioning block on the top bending mechanism clamps the other end of the steel pipe, and a heating device is used to heat the bending part of the steel pipe Heating is carried out, and the lateral movement distance and longitudinal movement distance of the steel pipe are tested by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com