Squeezer

A technology of extruder and pressure roller, which is applied in the field of toothpaste extrusion device, and can solve the problem that the amount of toothpaste extrusion is difficult to control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

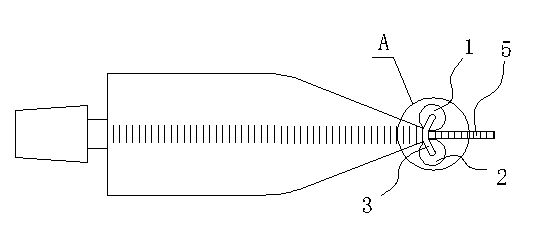

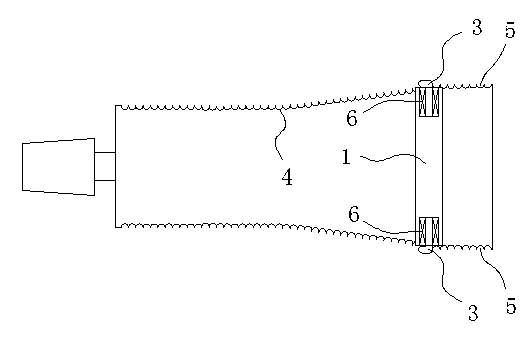

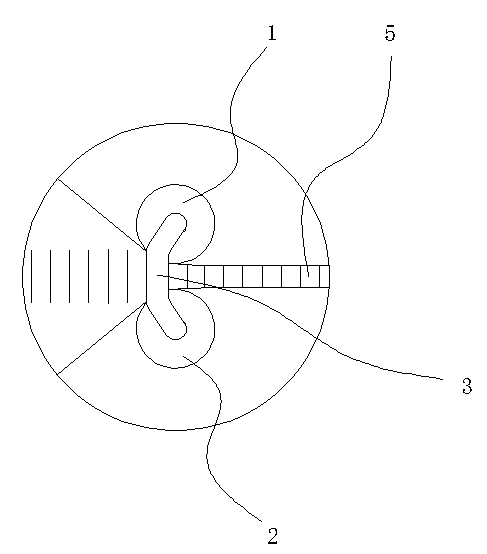

[0013] Such as Figures 1 to 3 Shown, a kind of extruder of the present invention comprises the upper pressure roller 1 that is arranged on the toothpaste bag upper bag surface and the lower pressure roller 2 that is arranged on the toothpaste bag lower bag surface, and described upper pressure roller 1 and lower pressure roller 2 pass through The two U-shaped connecting rods 3 arranged at their two ends are connected. The specific connection method is: each of the U-shaped connecting rods 3 has an upper end and a lower end, and the upper end is connected to the end of the upper pressure roller 1 through the bearing 6. The lower end is rotationally connected with the end of the lower pressure roller 1 through the bearing 6, and the middle part of the U-shaped connecting rod 3 (that is, the "U" bottom of the U-shaped connecting rod) is connected to the outlet end of the toothpaste bag. Bending; the gap between the upper and lower pressure rollers 1, 2 is equal to the sum of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com