Photocurable glue adhesion device adopting improved structure

A technology of light-curing glue and improving structure, which is applied in the direction of coating liquid on the surface, coating and other directions, can solve the problems of products prone to abnormal coating, difficult to accurately measure the glue extrusion amount, and reduce the yield of finished products, etc. Achieve the effect of improving product processing quality, simple and reasonable structure setting, and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the drawings.

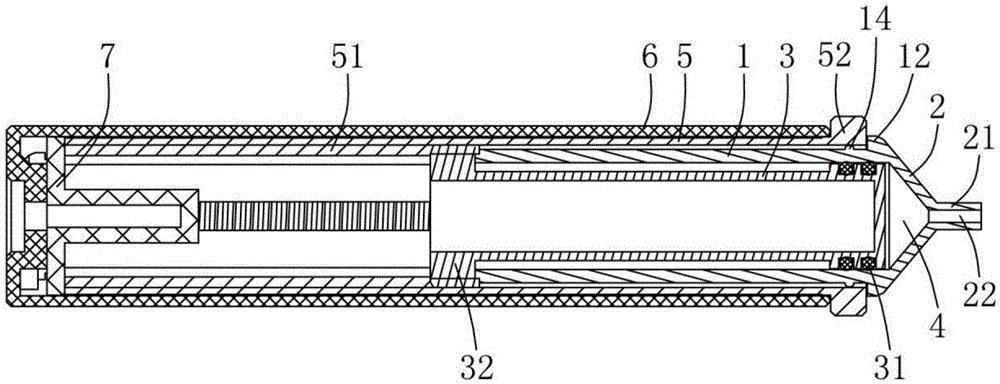

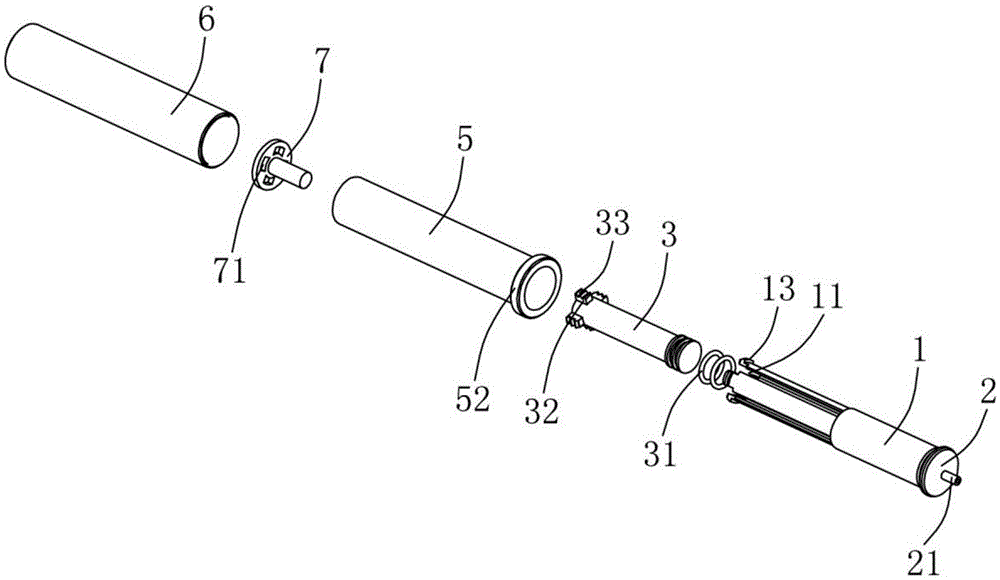

[0021] Such as figure 1 with figure 2 The light-curing glue bonder with an improved structure shown includes a main barrel 1 and a glue outlet 2 provided at the front end of the main barrel 1. Preferably, the main barrel 1 and the glue outlet 2 are integrated and fixedly connected. The main cylinder 1 is provided with a propelling piston 3, and an accommodating cavity 4 is formed between the main cylinder 1, the glue outlet 2 and the propelling piston 3. In order to prevent the leakage of glue, the front end of the propelling piston 3 is embedded and sealed with the main cylinder 1. Matching sealing ring 31. A glue nozzle post 21 is extended in the center of the glue outlet 2, and the glue nozzle post 21 is provided with a shaft hole 22 communicating with the accommodating cavity 4 along the axial direction. During operation, the shaft hole 22 serves as a channel for conveying light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com