Semitrailer with inverted plate springs

A technology for transporting vehicles and placing plates, which is applied in the direction of springs, leaf springs, springs/shock absorbers, etc., and can solve problems such as reverse deformation of leaf springs, easy breakage of bolts, and hidden dangers of driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

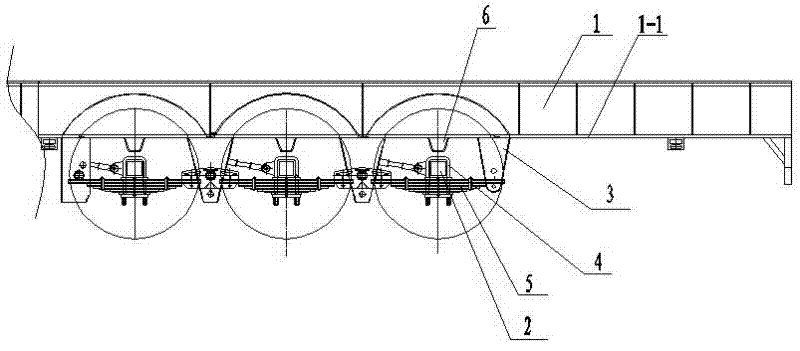

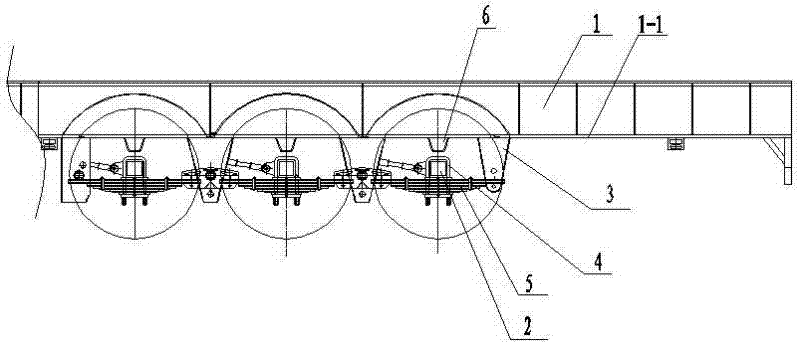

[0007] Such as figure 1 As shown, the present invention comprises a vehicle frame assembly 1 and a wheel axle assembly 2 arranged transversely, and a suspension assembly 3 is fixedly connected to the lower end of the longitudinal beam of the vehicle frame assembly 1, and a " U"-shaped bolt 4, on the "U"-shaped bolt 4, a reversed leaf spring 5 is arranged, and the front and rear ends of the reversed leaf spring 5 are rested on the corresponding suspension assembly 3 respectively.

[0008] The longitudinal beam lower wing plate 1 - 1 of the vehicle frame assembly 1 directly above the vehicle axle of the wheel axle assembly 2 is welded with a hard block 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com