Steel rope separating device for checking elevator limiter

A technology of elevator speed limiter and detachment device, which is applied in the direction of transmission elements or pulley ropes or cables, textile cables, belts/chains/gears, etc. It can solve the problems of easily damaged wire ropes, large gap between jaws, and wire rope slippage, etc. Achieve the effect of ensuring the safety of life and property, not easy to loosen, and strong clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

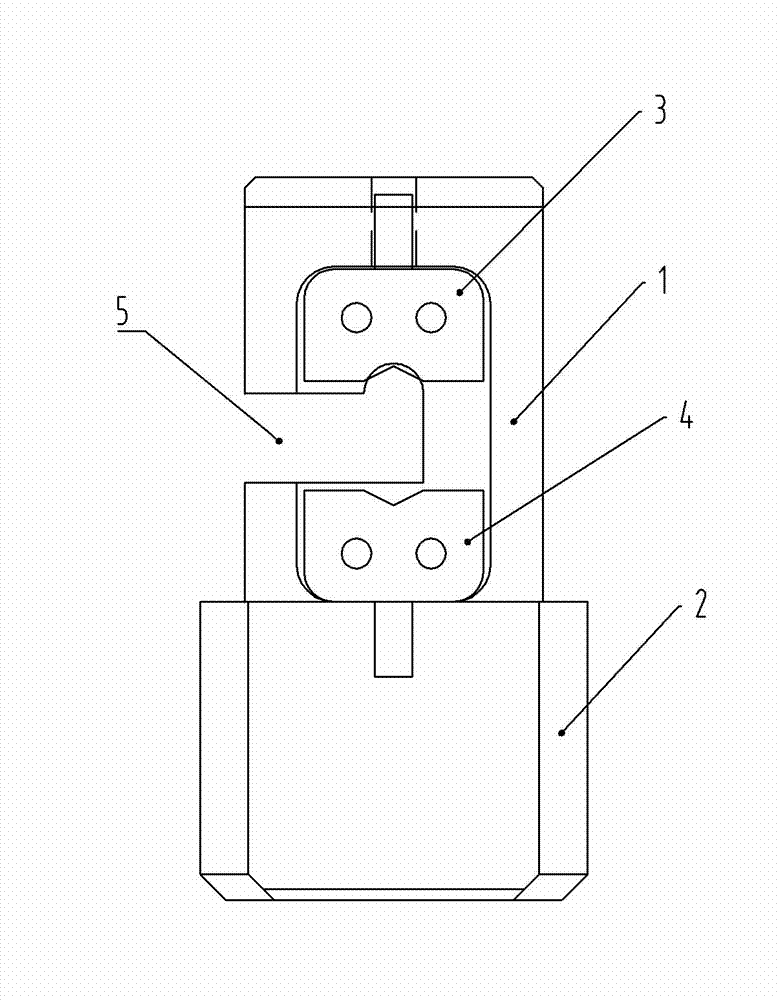

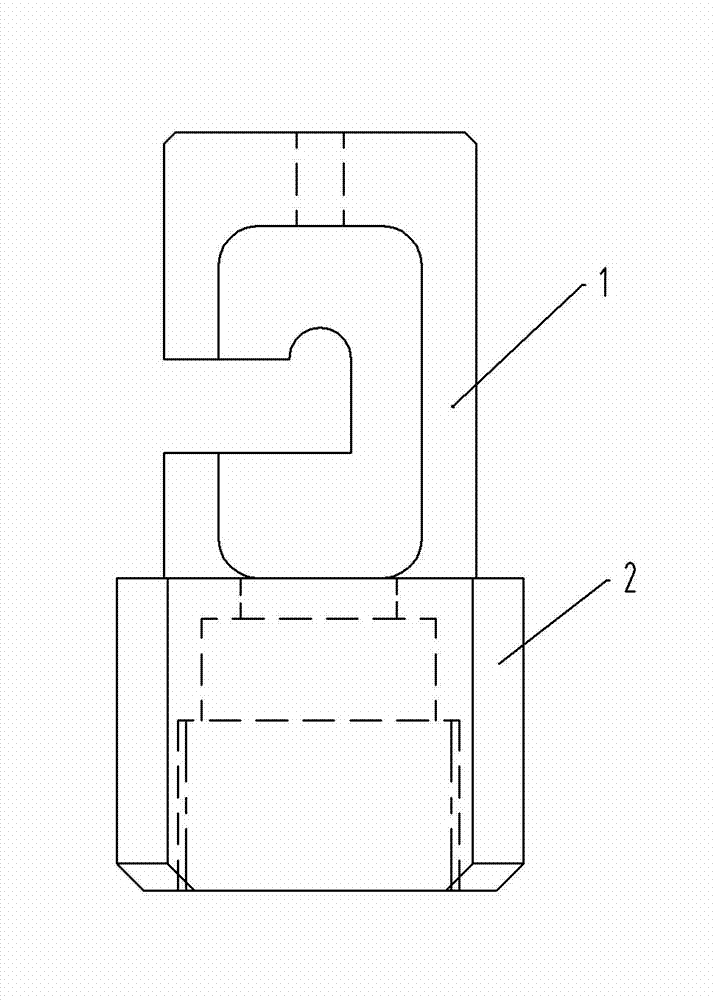

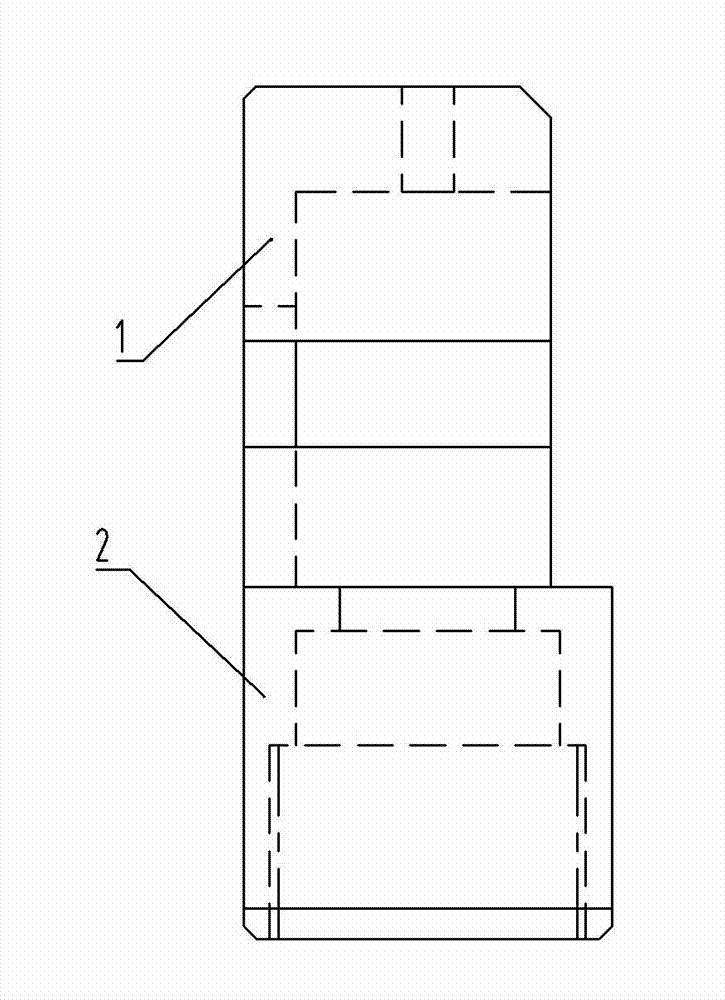

[0021] Embodiment one: see Figure 1 ~ Figure 3 . The steel wire rope detachment device for checking the speed limiter of an elevator according to the present invention includes a hydraulic force application mechanism and a clamping head. The hydraulic force application mechanism includes a fixed handle and a pressurized movable handle as a hydraulic cylinder, extending from the front end of the fixed handle Out of the piston rod, the structure of the clamping head is as follows figure 1 As shown, it includes a clamp sleeve 1 with a hollow inner cavity and a connector 2 integrally connected with it. The front and rear ends of the hollow inner cavity of the clamp sleeve 1 are respectively movable to match the fixed block 3 and the slider for clamping the steel wire rope. 4. The fixed block and the slider are provided with a "V"-shaped opening groove along the direction of the steel wire rope, and the fixed block and the slider for clamping the steel wire rope in the side wall ...

Embodiment 2

[0022] Embodiment two: see figure 1 , figure 2 , image 3 , Figure 4 , the wire rope release device for checking the speed limiter of the elevator in this embodiment is different from the first embodiment, such as Figure 4 As shown, the fixed block 3 and the slider 4 clamping the steel wire rope are respectively provided with a guide post 6 at the center of the opposite outer end surface, and the fixed block 3 is installed on the upper part of the hollow inner cavity of the clamp sleeve through its guide post, so that The guide column 6 is nested and installed in the through hole matched with the guide column provided on the top wall of the fixture sleeve; the slider 4 is connected with the top end of the piston rod through its guide column, and is located at the top center of the piston rod. There is a slider guide column embedded hole.

[0023] The wire rope detachment device for the inspection of the elevator speed governor, along the direction of the wire rope, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com