High-temperature high-pressure steam split-ranging valve control device

A high-temperature, high-pressure, valve control technology, applied in the direction of the valve device, valve operation/release device, valve lift, etc., can solve the problems of increasing the force on the valve disc bolts, aggravating the vibration and wear of the regulating valve, and achieving accuracy and stability. Controlling, increasing intensity, reducing jitter effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

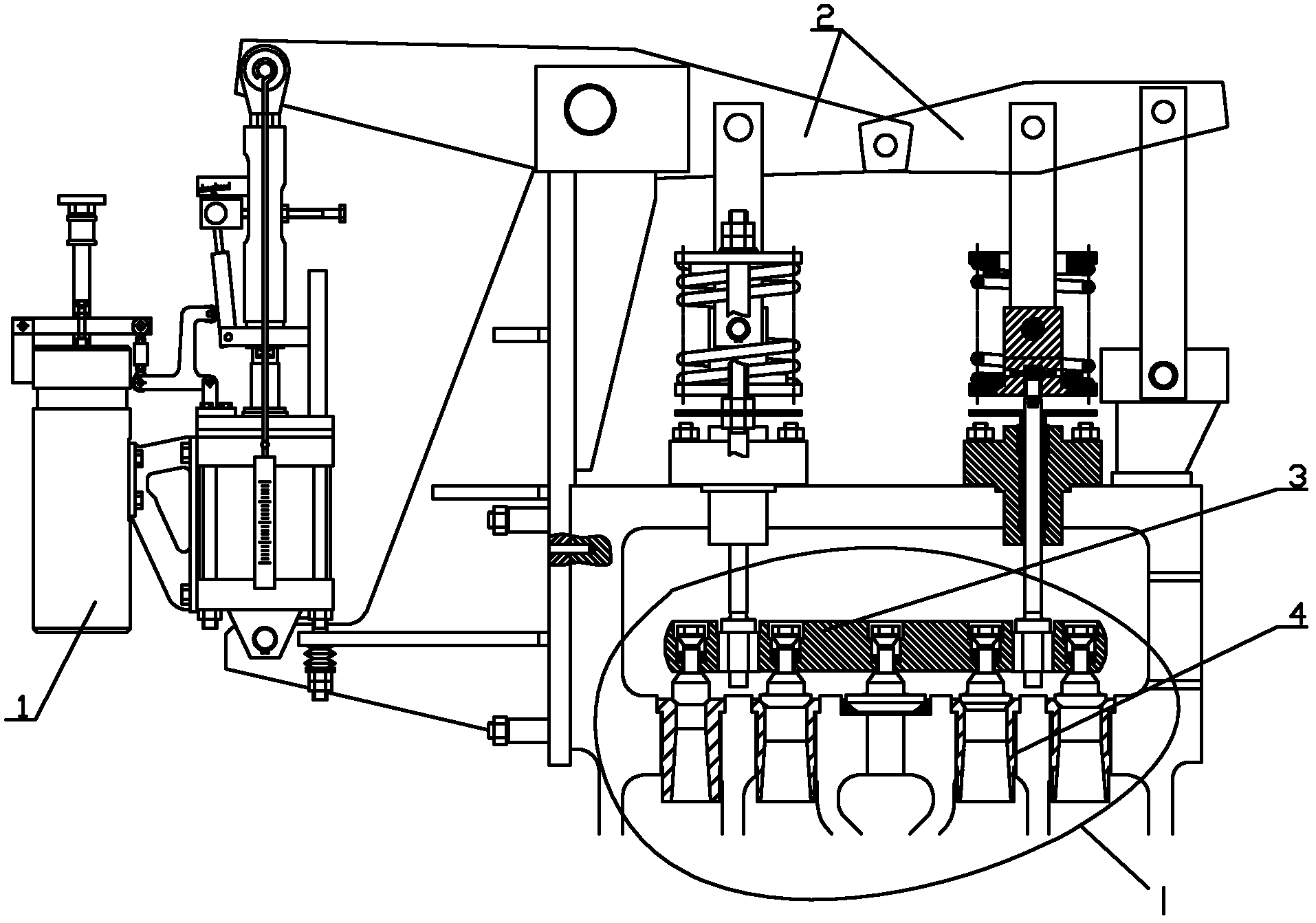

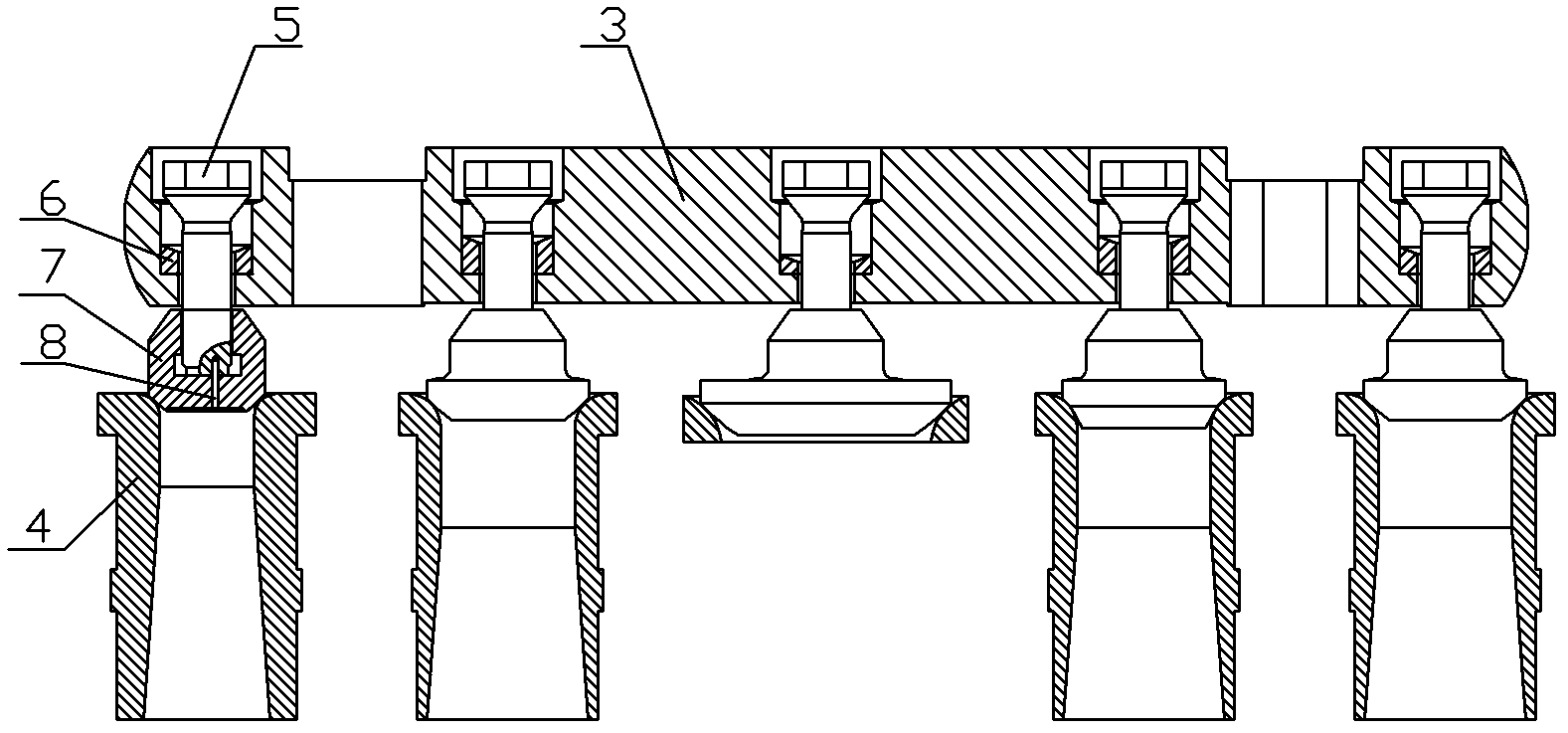

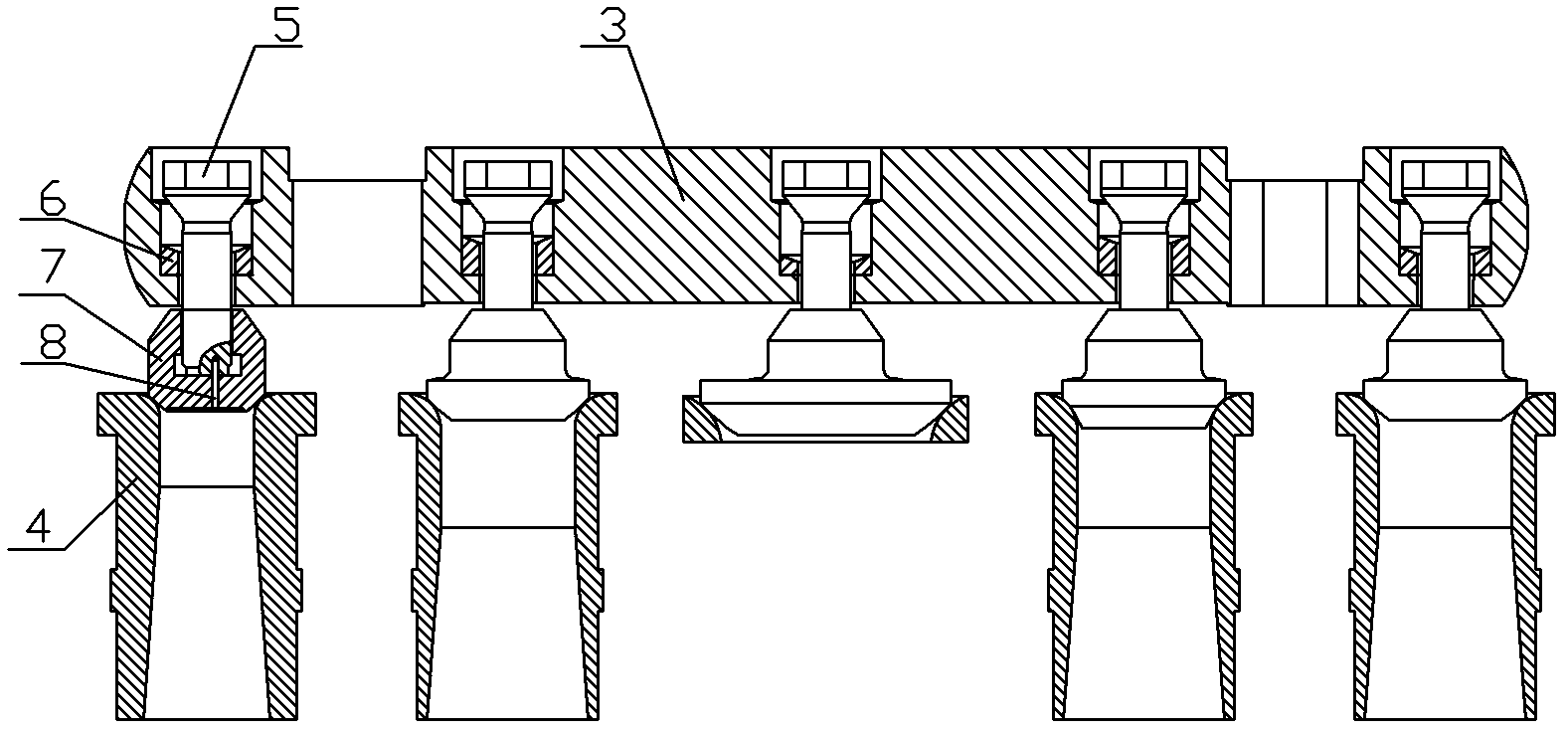

[0014] Such as figure 2 The high-temperature and high-pressure steam split-range valve control device shown includes a valve beam 3, and a plurality of valve discs 7 are respectively connected to the valve beam 3 through valve disc bolts 5, and the valve discs 7 cooperate with the valve seat 4, and the valve beams 3 is provided with a stepped hole for piercing the valve disc bolt 5, and a bushing 6 is provided in the stepped hole. The valve disc bolt 5 passes through the valve beam 3 and the bushing 6, and its upper end can be limited by the bushing 6. Its lower end is threaded and fixed with the valve disc 7; wherein, the bushing 6 and the valve beam 3 are clearance fit, the valve disc bolt 5 and the valve beam 3 and the bushing 6 are clearance fit, and the upper end of the valve disc bolt 5 does not exceed The top surface of the valve beam 3, that is, the 5 heads of the valve disc bolts are hidden in the through hole, and the left and right ends of the valve beam 3 have a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com