Aluminum shell for rapid plug-in type capacitor

A capacitor and aluminum casing technology is applied in the field of aluminum casings for capacitors to achieve the effects of cost reduction, fast and convenient plug-in fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

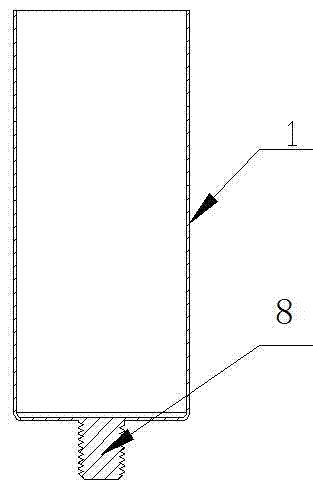

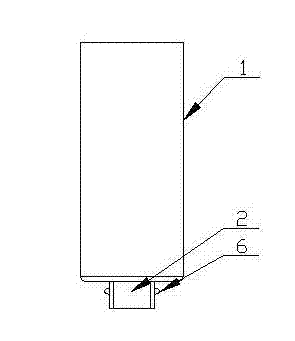

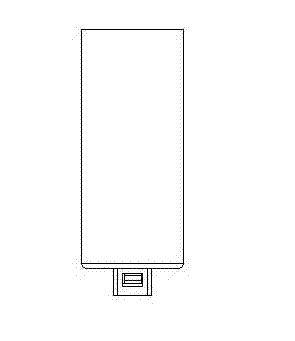

[0019] see Figure 2-7 , The invention discloses an aluminum casing for a fast plug-in capacitor. As shown in the figure: it includes a housing 1, the bottom of the housing 1 is provided with a fixed plug-in part 2, the fixed plug-in part 2 has a hollow inner cavity 3 and the corresponding fixed plug-in part 2 communicates with the hollow inner cavity The elastic cards on both sides protrude from the hole 4; an elastic card 5 is composed of an elastic bar 7 and an elastic pressing part connected to the two ends of the elastic bar 7; The elastic pressing parts 6 at the end are all exposed outside the elastic card protruding hole 4 .

[0020] When the capacitor needs to be installed and fixed, it is necessary to open an insertion hole corresponding to the shape of the fixed insertion part at the fixed installation position, and then insert the fixed insertion part 2 provided at the bottom of the capacitor case 1 into the insertion hole. When inserting, the elastic pressing par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com