Double-sided cutting inserts for high feed milling

A cutting blade, double-sided technology, applied in the direction of milling cutting blades, milling cutters, forming knives, etc., can solve the problems such as undesirable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

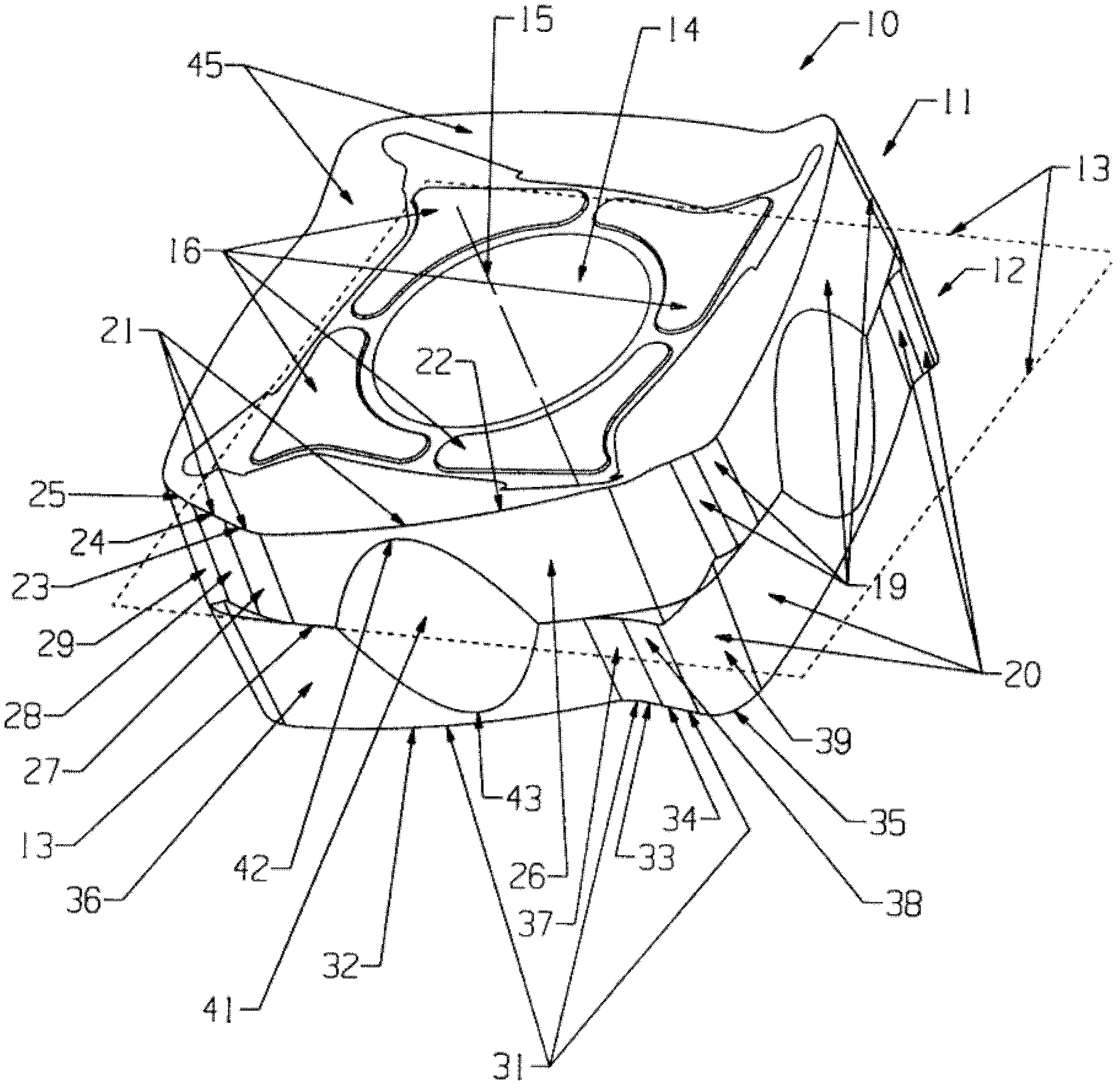

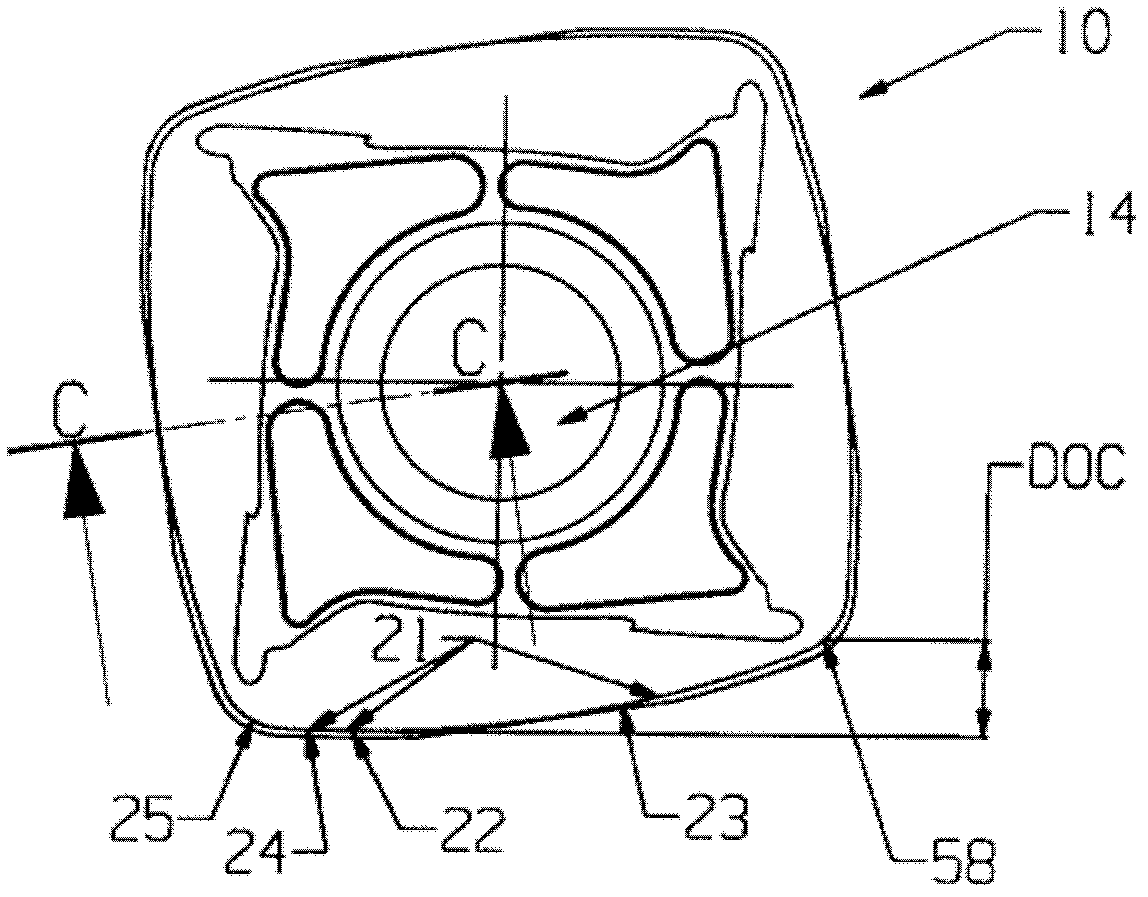

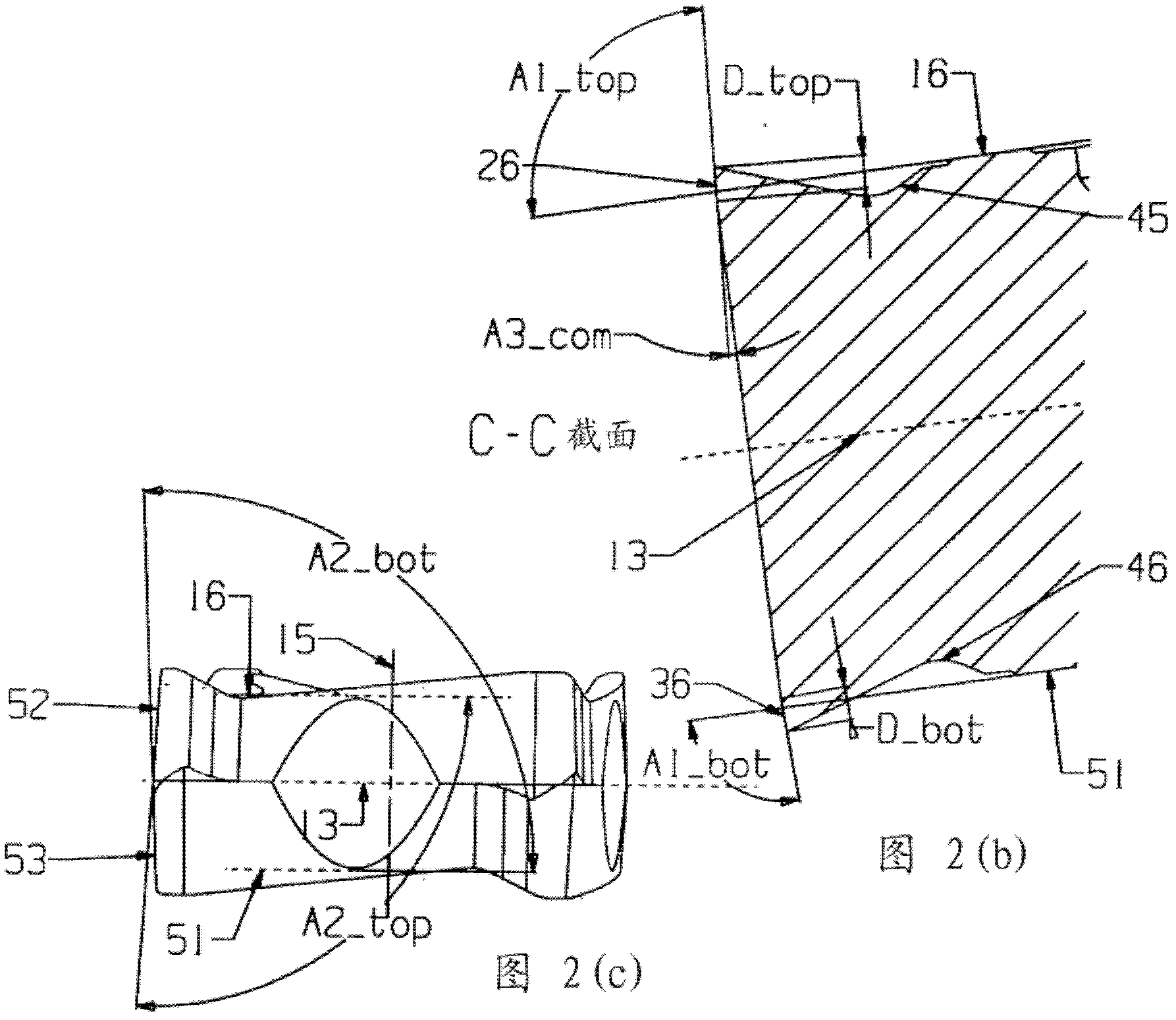

[0025] It will be appreciated that the specific description of the invention has been simplified herein to illustrate only those elements and constraints that are relevant to a clear understanding of the invention, while other elements have been removed for the purpose of clarity. Those of ordinary skill in the art, upon consideration of this description of the invention, will realize that other elements and / or constraints may be desired in order to practice the invention. However, since such other elements and / or constraints can be readily determined by those of ordinary skill in view of this description of the invention and are not required for a complete understanding of the invention, no reference to such elements and / or constraints is provided herein. Discussion of constraints. For example, as discussed herein, insert embodiments of the present invention may be produced in the form of face milling inserts and other inserts for material removal. The method of manufacturin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com