Anti-creeping and anti-seepage safe power socket plate

A technology of safe power supply and anti-water seepage, applied in the direction of circuits, electrical components, bases/housings, etc., can solve problems such as sealing rings not being waterproof, electric shock accidents, short circuits, etc., to achieve good safety and waterproof performance, prevent electric shock accidents, The effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

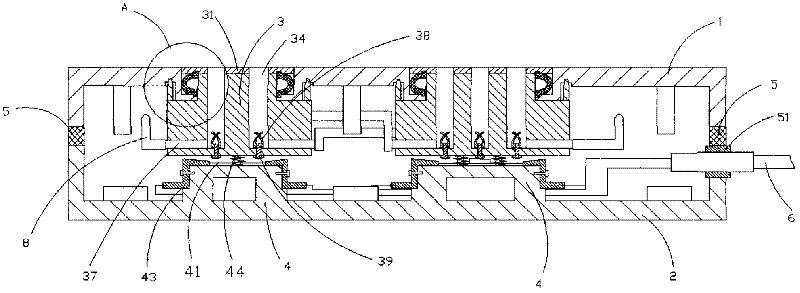

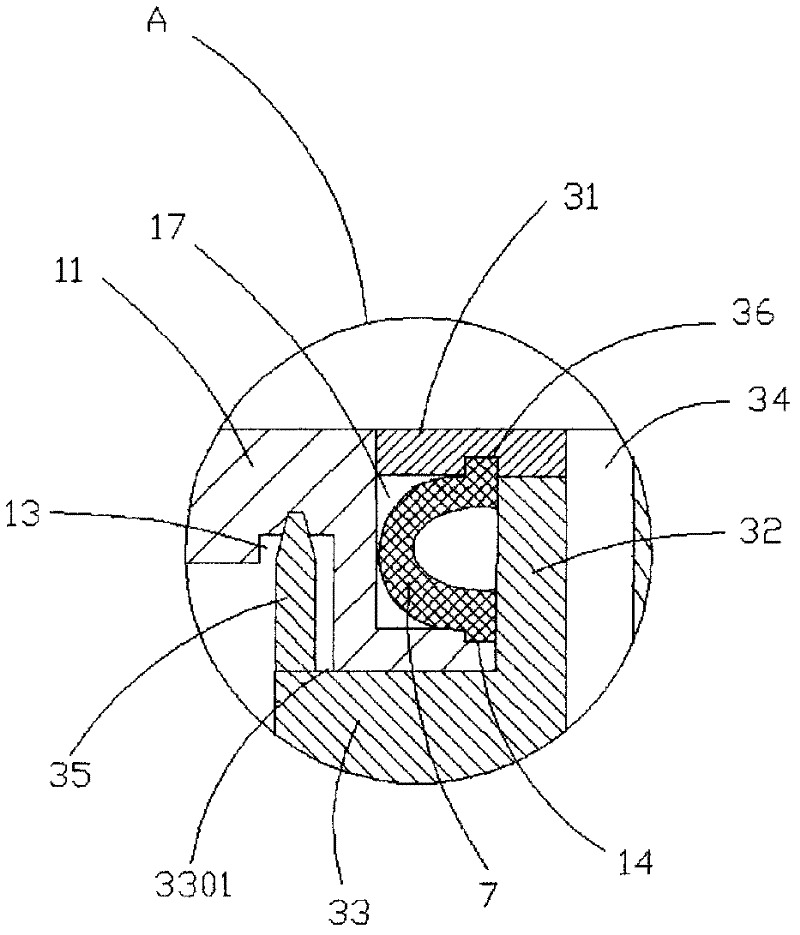

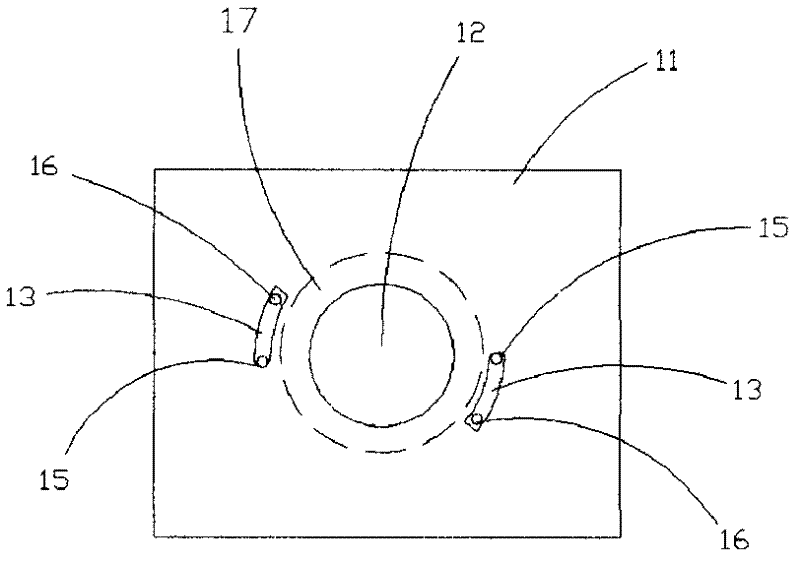

[0022] Such as Figure 1-8 As shown, a safety power socket board that prevents leakage and water seepage includes an upper casing 1, a lower casing 2, and a socket unit 3, and a sealing gasket 5 is provided at the joint between the upper casing and the lower casing. The upper housing panel 11 is provided with at least one hole 12 for installing the socket unit, and a locking member 18 is provided above the socket unit next to the hole. In this embodiment, the socket unit 10 is provided with two sockets for live wire and neutral wire, and the socket unit 101 is provided with three sockets for live wire, neutral wire and ground wire. The upper part 32 of the socket unit 3 is placed in the hole 12 of the upper housing panel 11 in a sliding manner, and the upper end face cover plate 31 of the socket unit is embedded in the annular groove 17 of the hole of the upper housing panel matching it. And it is flat with the upper shell panel 11, and can slide up and down when the cover pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com