Roller bracket capable of swinging

A technology of rollers and rocking plates, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc. It can solve the problems that the rollers can only rotate and cannot be adjusted horizontally, so as to achieve convenient reset adjustment, save manpower and material resources, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

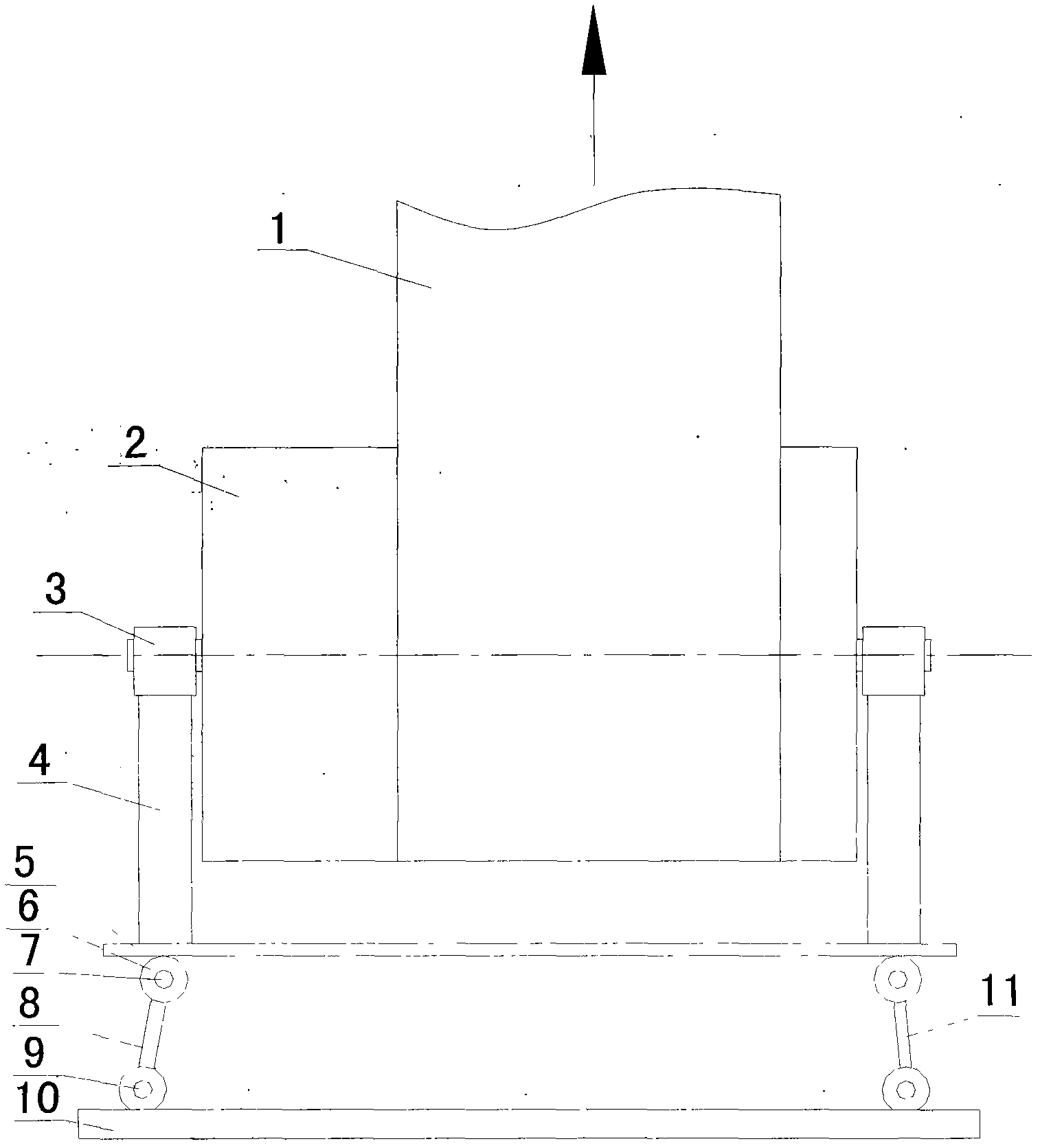

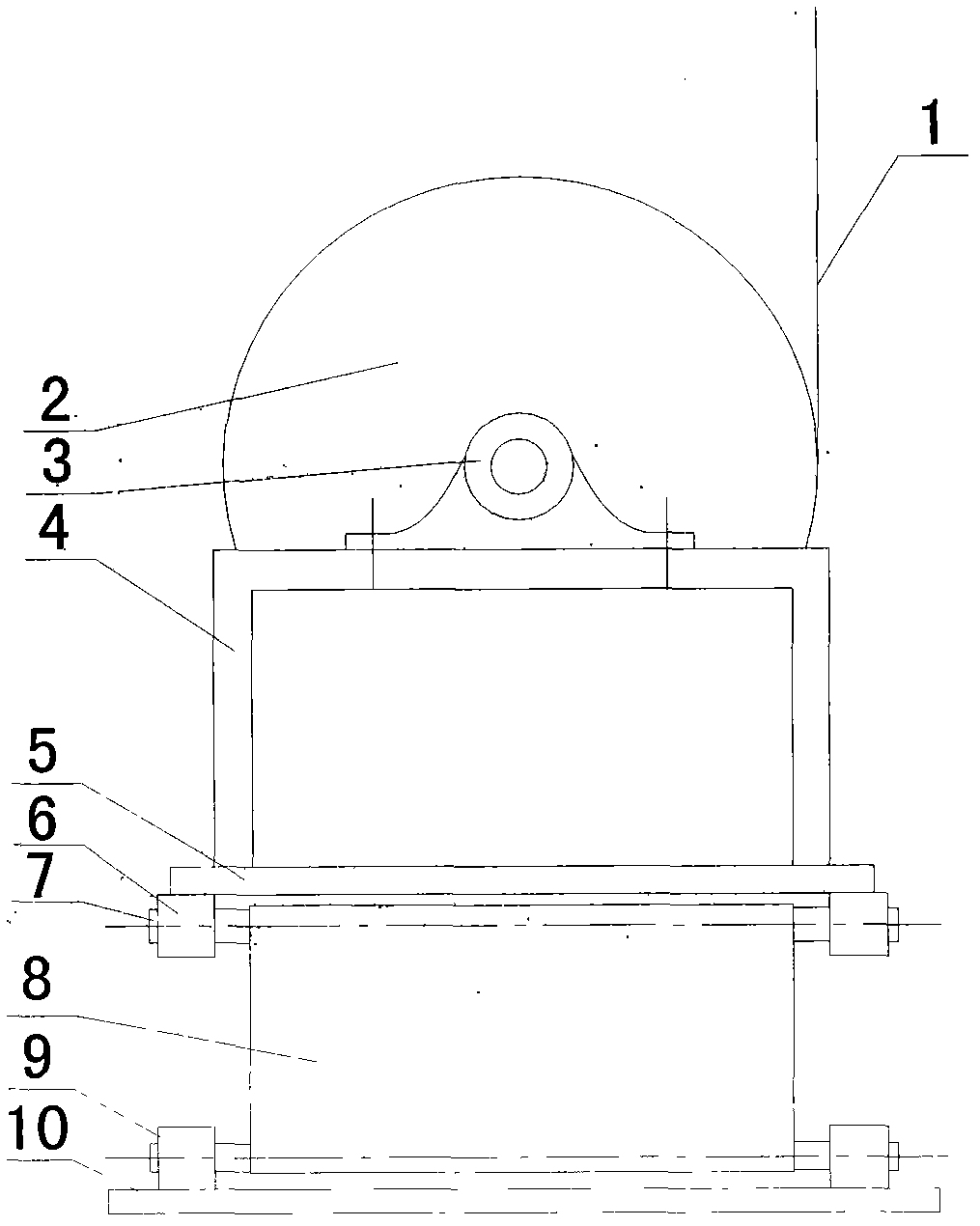

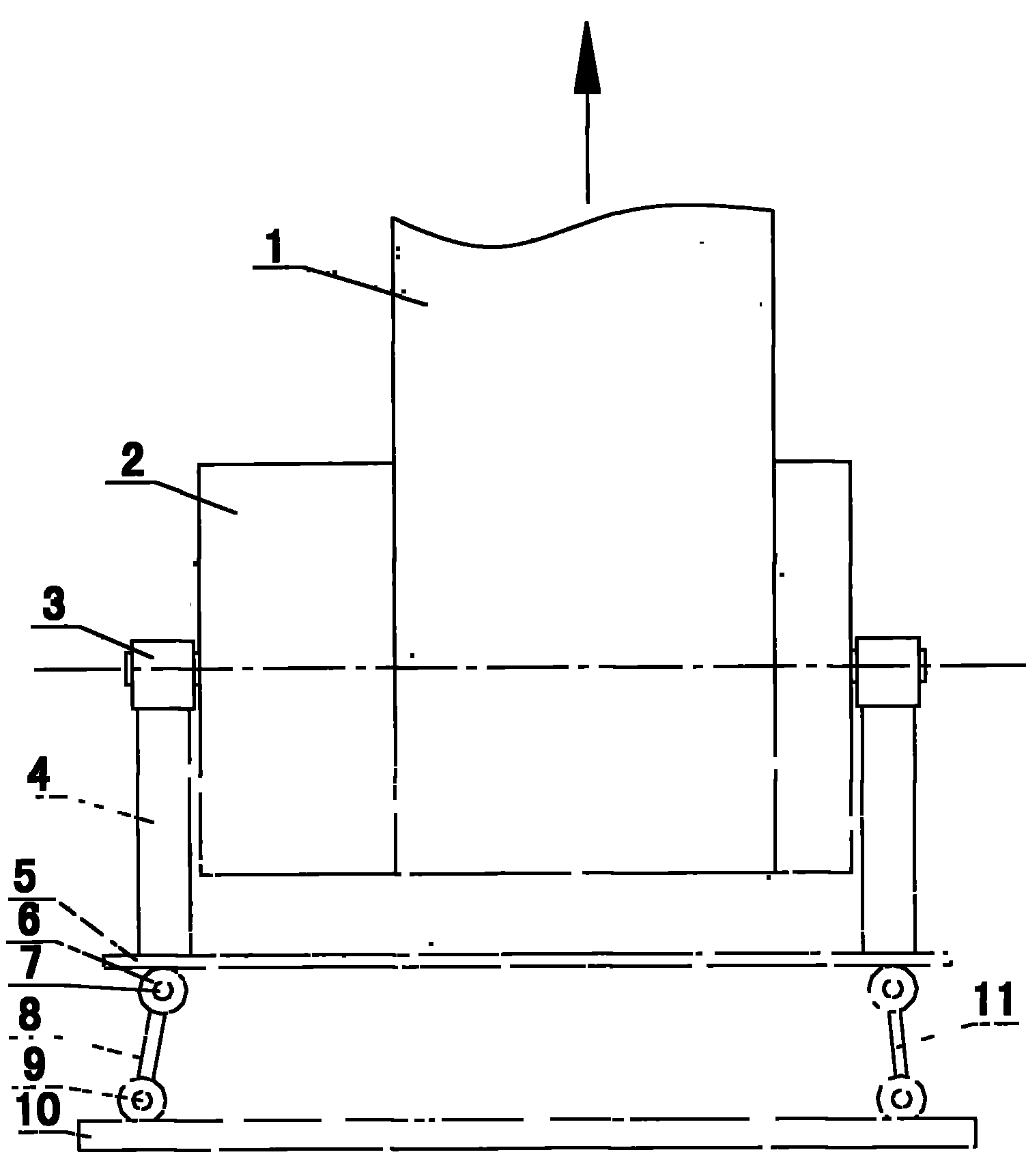

[0014] Such as Figures 1 to 2 As shown, a specific embodiment of the present invention is provided. In the figure, the steel strip 1 moves along the direction of the arrow on the roller 2, and the two shafts of the roller 2 are installed on a pair of first axle sleeves 3 on the bracket 4 , the bracket 4 is fixed on the bottom plate 5, when the steel belt 1 moves under the drive of the motor, the roller 2 rotates on the bracket 4, and there are two rocking plates under the bottom plate 5: the first rocking plate 8 and the second rocking plate 11, two There is a rotating shaft 7 on the top and bottom of each rocking plate, and its two ends are respectively inserted into two pairs of second shaft sleeves 6 fixed on the lower end of the bottom plate and two pairs of third shaft sleeves 9 fixed on the base 10; The plate can stably support the roller 2, and the positions of the two rocking plates are set to be non-parallel to each other, and when one of them is vertical, the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com