Green tea fixation and carding equipment

It is a technology for clearing green strips and equipment, which is applied in tea processing before extraction, etc. It can solve the problems of low degree of automation and low thermal efficiency, and achieve the effects of reduced energy consumption, high thermal efficiency, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

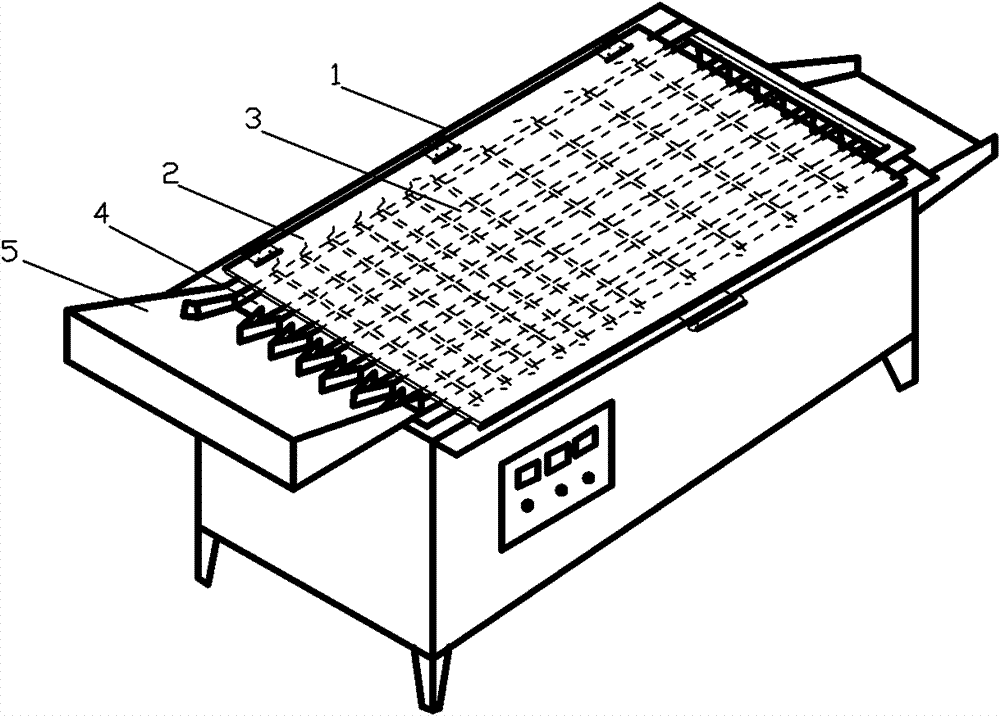

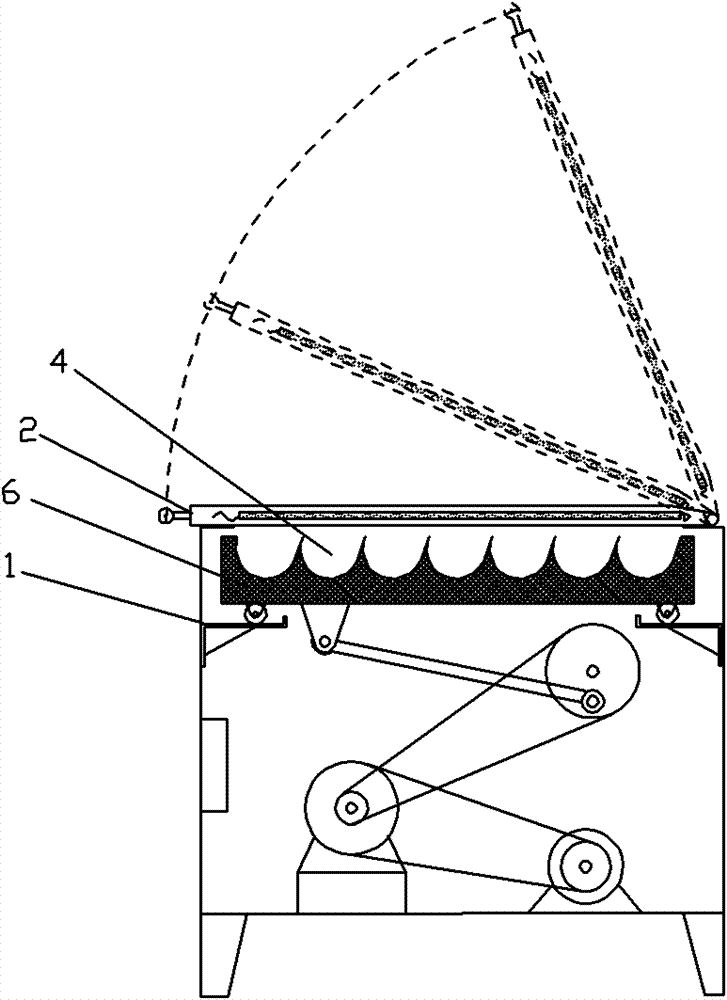

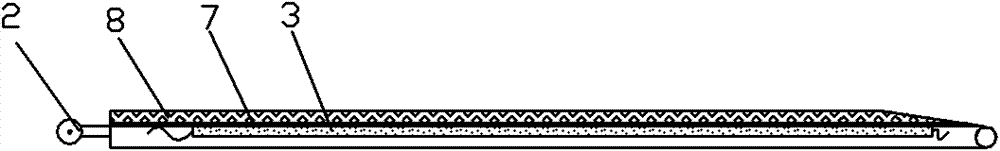

[0012] A kind of green tea clearing and stripping equipment of the present embodiment is as follows: figure 1 and figure 2 As shown, the equipment is mainly composed of a frame 1, a reciprocating swing frying multi-slot pot 4, a hatchback heating device 2 above the multi-slot pot and a heat insulation pad 6 below the multi-slot pot. Cross section is housed in the frame 1 and is the multi-groove pot 4 of U-shaped undulation. The inlet end of the multi-slot pot 4 is provided with a tea distribution tray 5 . One side of the upper surface of the frame 1 is hinged to support the far-infrared heating device 2 . The far-infrared heating device 2 has a heat-insulating mounting plate 8 that can be covered on the multi-slot pot 4 . A group of far-infrared heating tubes 3 arranged at intervals are arranged on the lower surface of the heat-insulating mounting plate 8 . A reflective film 7 is installed between the heat insulation mounting plate 8 and the far-infrared heating tube 3 . ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap