Full-automatic forming device for metal clothes hanger of cloth wardrobe

A molding device and clothes hook technology, applied in the direction of molding tools, feeding devices, positioning devices, etc., can solve the problems of increasing production costs, wasting manpower, and reducing economic benefits, so as to improve production efficiency, reduce production costs, and improve production efficiency. The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through specific embodiments.

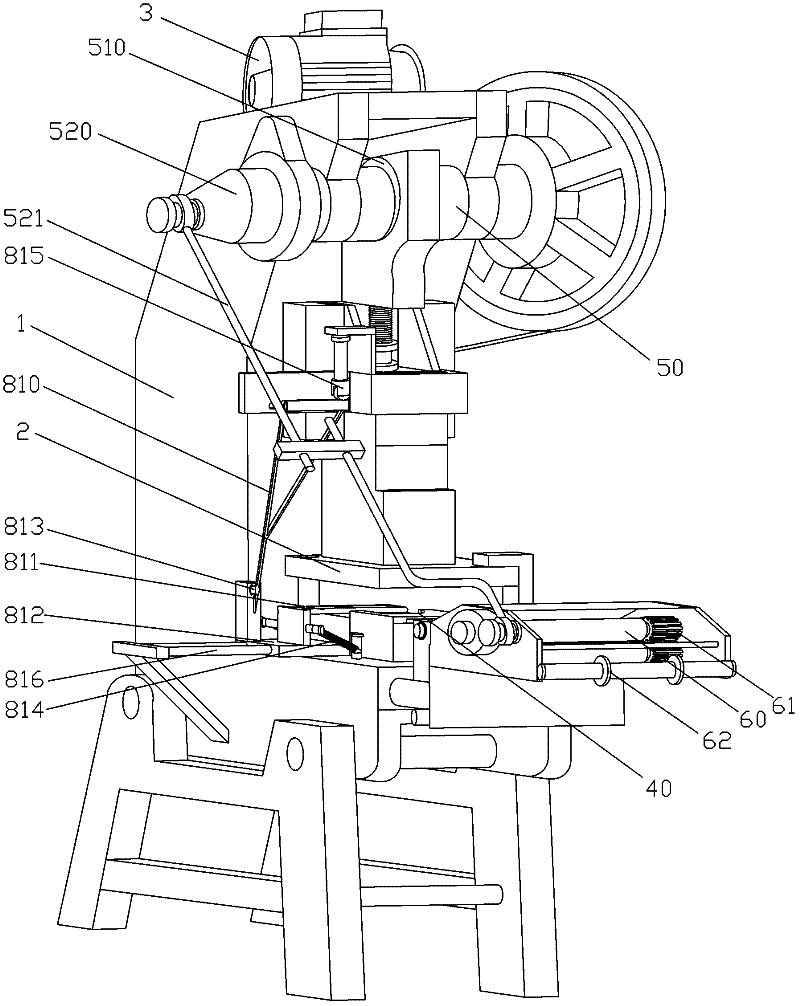

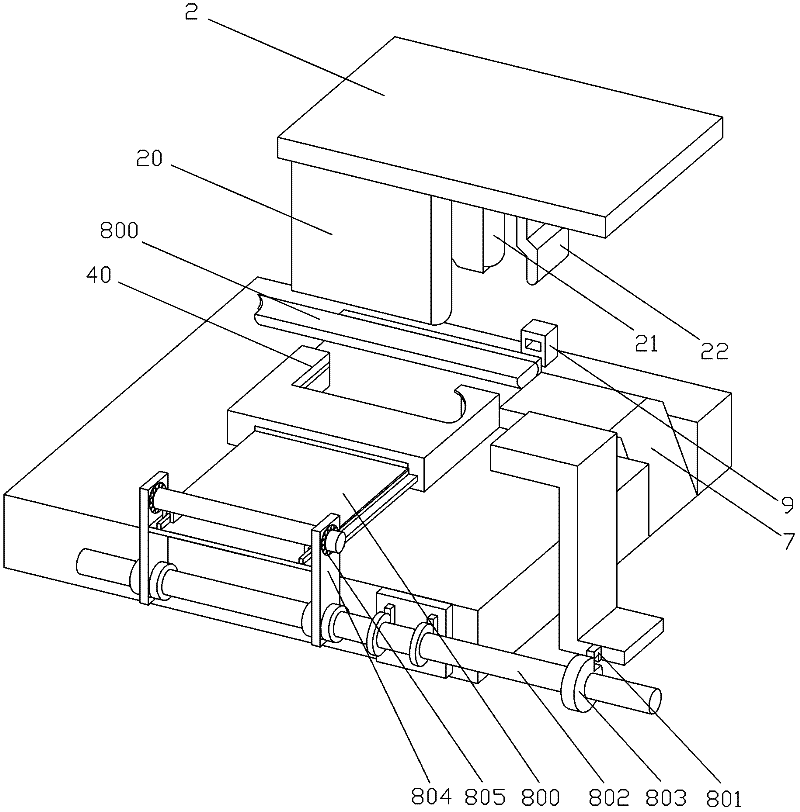

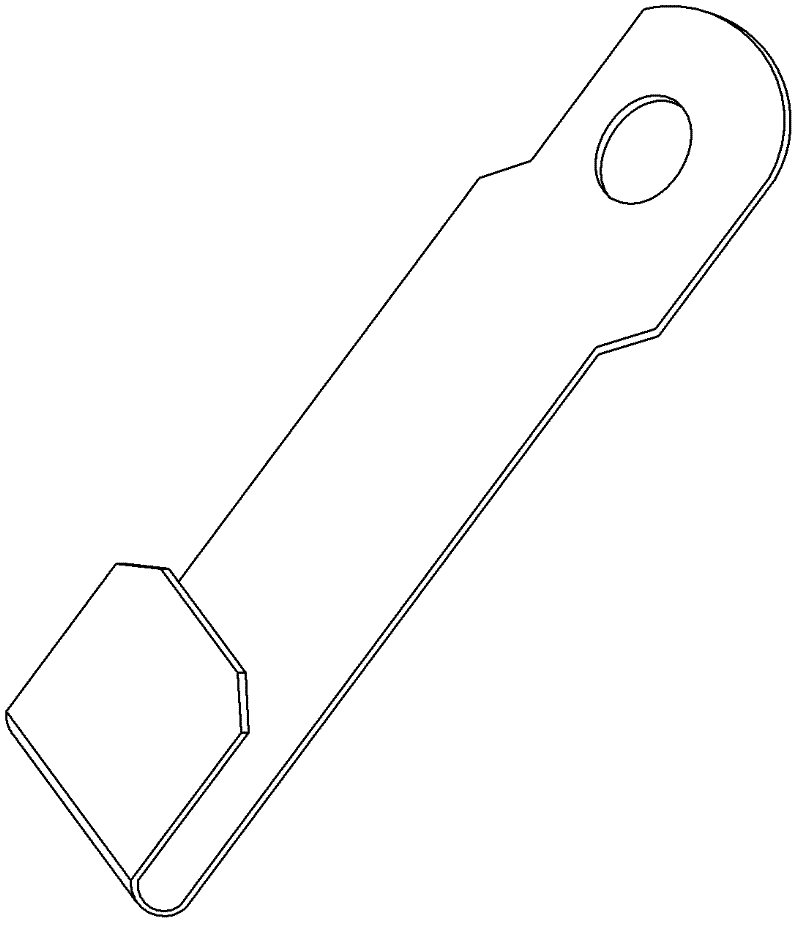

[0020] refer to figure 1 , figure 2 and image 3 , a fully automatic forming device for a cloth wardrobe metal clothes hook, comprising a frame 1, an upper pressing device 2 movably arranged on the frame 1, connected to the upper pressing device 2 through a transmission device for driving the upper pressing device 2 The driving motor 3 and the automatic control device for vertical lifting also include a synchronous feeding device. The upper pressing device 2 is provided with a first upper die 20 for punching and blanking, and a second upper die 21 for punching and bending the workpiece. and the third upper mold 22 for workpiece flanging, the frame 1 is provided with the first lower mold 40, the second lower mold 40, the second lower mold, which are located below the upper pressing device 2 and are opposite to the first, second, and third upper molds. Mold and the 3rd bottom mold al...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap