Air heat exchanger for air conditioner

An air heat exchanger, air heat exchanger technology, applied in evaporator/condenser, lighting and heating equipment, refrigeration components, etc., can solve the problems of large condensation pressure drop, small subcooling degree, liquid flashing, etc. To achieve the effect of overcoming the excessive condensation pressure drop and reducing the overall pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described in detail below in conjunction with the embodiments.

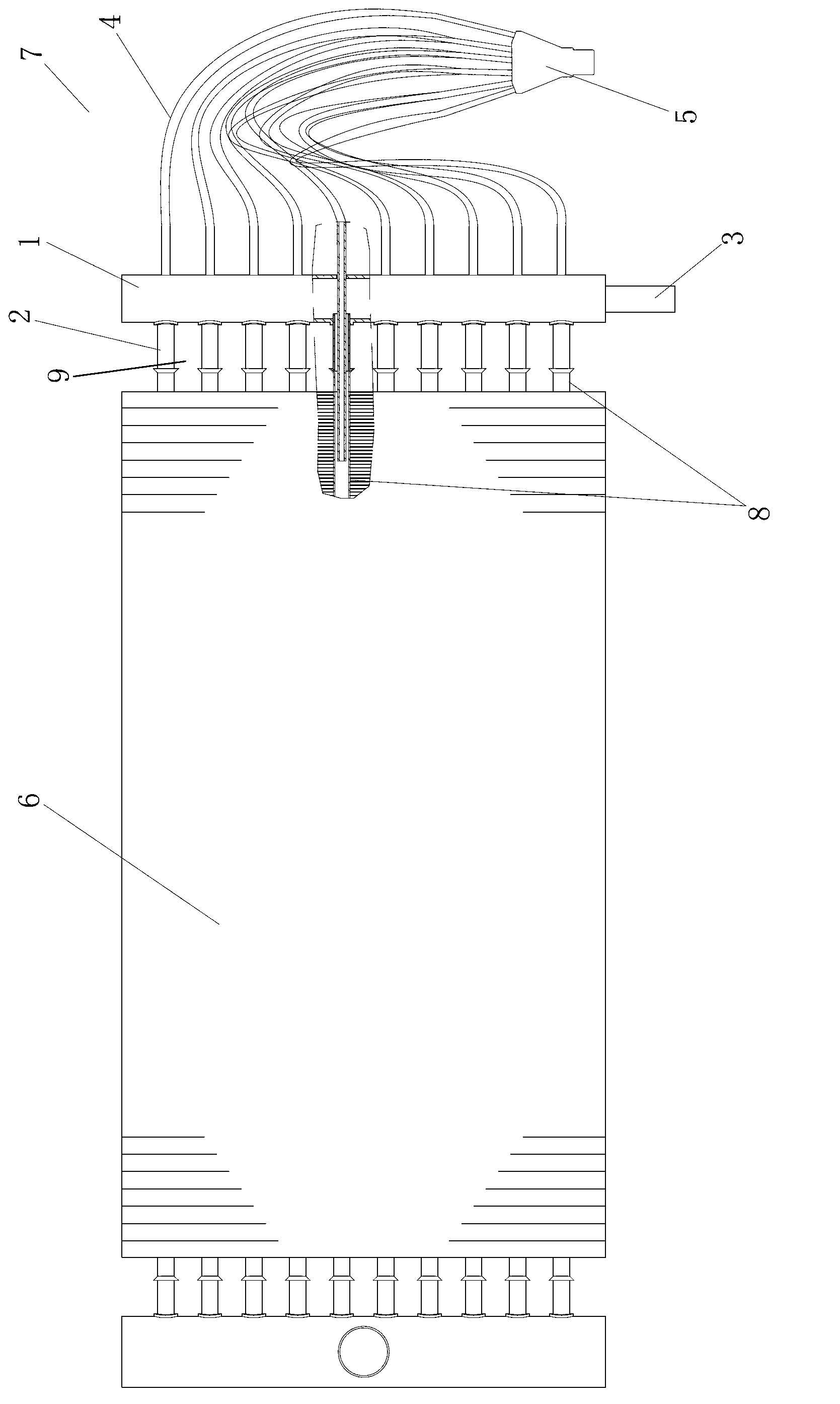

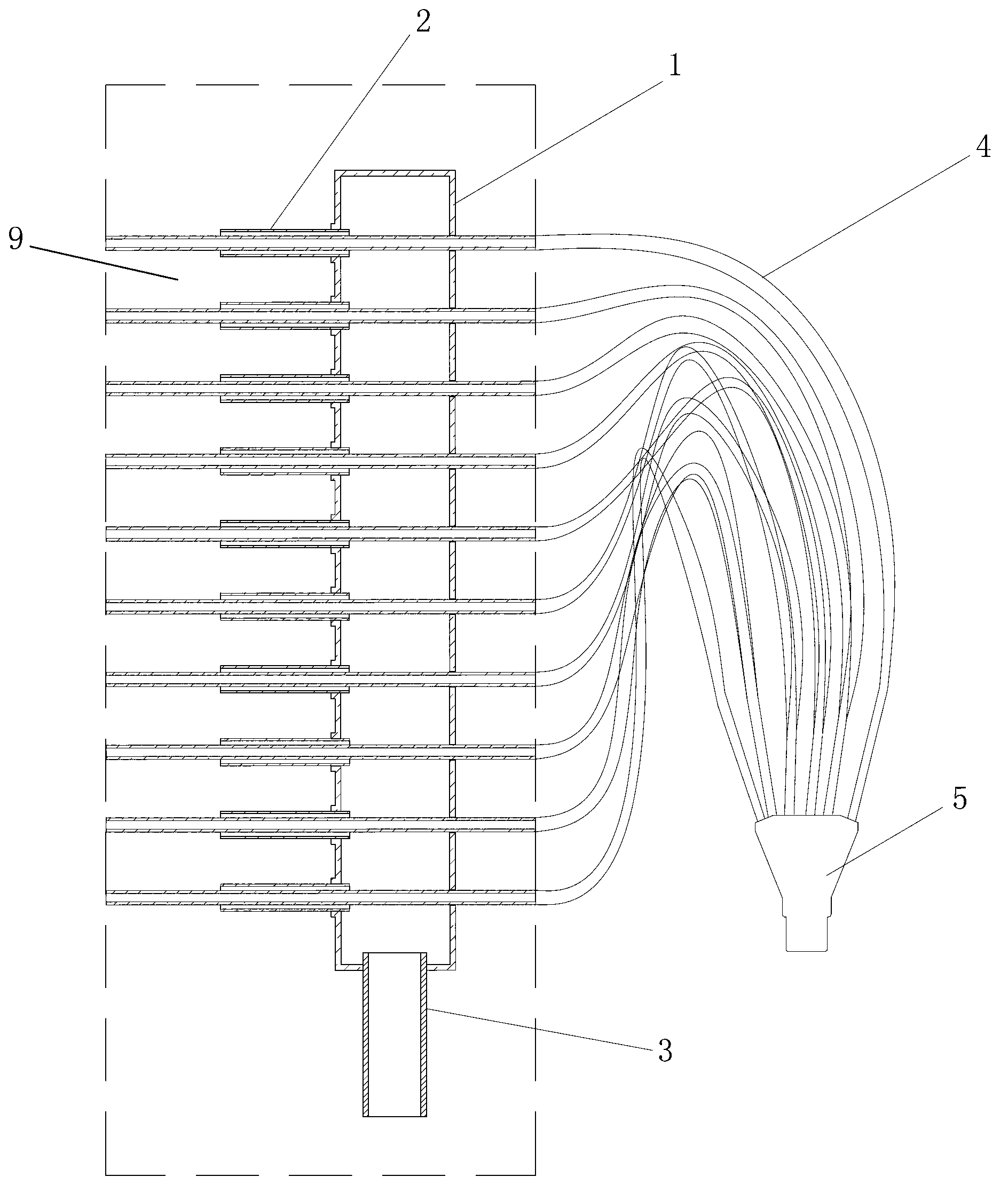

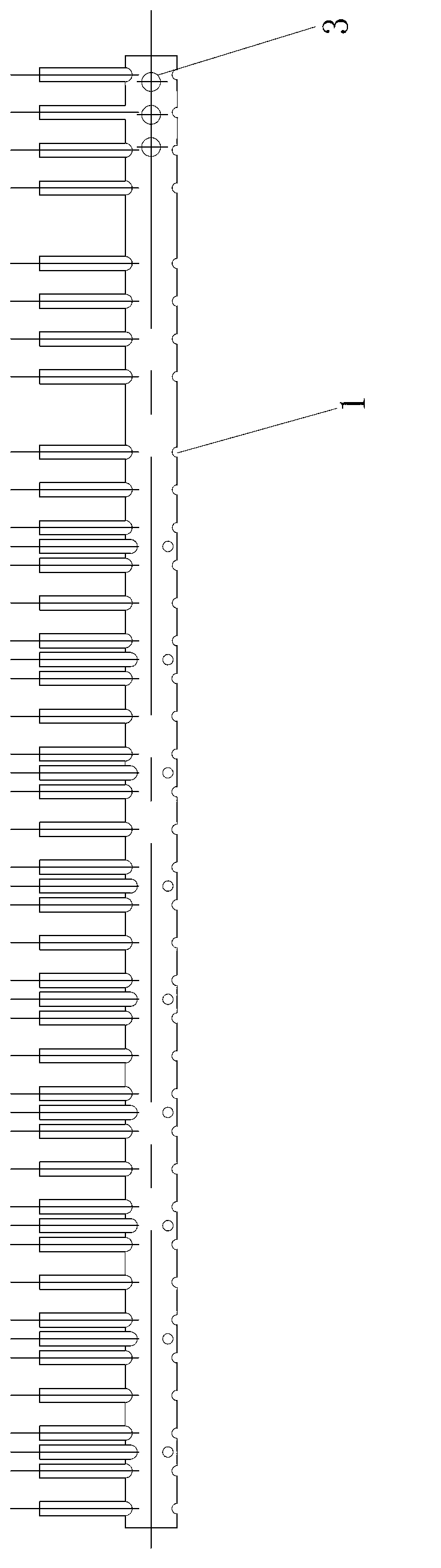

[0020] Such as figure 1 and figure 2 As shown, the air-conditioning air heat exchanger of Embodiment 1 of the present invention includes an air heat exchanger 6, and one side of the air heat exchanger 6 is provided with a collection and distribution device 7 connected to the main pipeline of the heat exchanger. The device 7 is composed of a tubular main body 1, a distribution pipe 2, a connecting pipe 3, a capillary tube 4 and a distributor 5. The collecting and distributing device 7 is integrally constructed or welded separately. The tubular main body 1 is a cylinder with both ends closed, and the tubular main body The length of 1 is 100-1500mm, the thickness of the pipe wall is 0.6-3mm, the pipe diameter is 25.4-108mm, and the pipe is made of pure copper. There are 40 distribution pipes 2 arranged in a line, and the number of columns is 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com