Coating composition and method of making and using the same

A composition and polymer technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as troubles, insufficient shelf life, environmental problems, etc., and achieve easy application, extended storage stability, and preventive protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0051] Instance

[0052] Unless otherwise specified, all parts, percentages, ratios, etc. in the examples and the rest of the specification are by weight. All contact angles reported in the examples are static contact angles reported in degrees.

[0053] The following abbreviations will be used in the examples below:

[0054] NPS1: 16.2% solids (nominal 15% solids) aqueous colloidal spherical silica dispersion, available as NALCO 2326 from NALCO Chemical Company (Naperville, IL);

[0055] NPS2: 16.5% solids (nominal 15% solids) aqueous colloidal spherical silica dispersion, available as NALCO 1115 from NALCO Chemical Company;

[0056] NPS3: 50% solid water-based colloidal spherical silica dispersion, available as NALCO1050 from NALCO Chemical Company;

[0057] NPS4: 20% solid water-based colloidal non-spherical silica dispersion, available as ST-UP from Nissan Chemical America Corporation (Houston, TX);

[0058] NPS5: 20% solid water-based colloidal non-spherical silica dispersion, avai...

Example Embodiment

[0091] Example 1

[0092] NPS1 (1.992 grams (g)) was mixed manually with 4.404 g deionized water. A 4.5% solid polyurethane dispersion masterbatch was prepared by manually mixing 5.125g PU1 and 32.113g deionized water at 22°C until uniform. A dispersion with a silica:polyurethane ratio of 9:1 was prepared by manually mixing diluted NPS and 0.787g 4.5% solid PU1 at 22°C until uniform. To this dispersion was added 2 drops of HCl, and the mixture was stirred. The dispersion was then diluted with deionized water to a total solid content of 0.5% by weight, and the pH was measured using pH test paper.

Example Embodiment

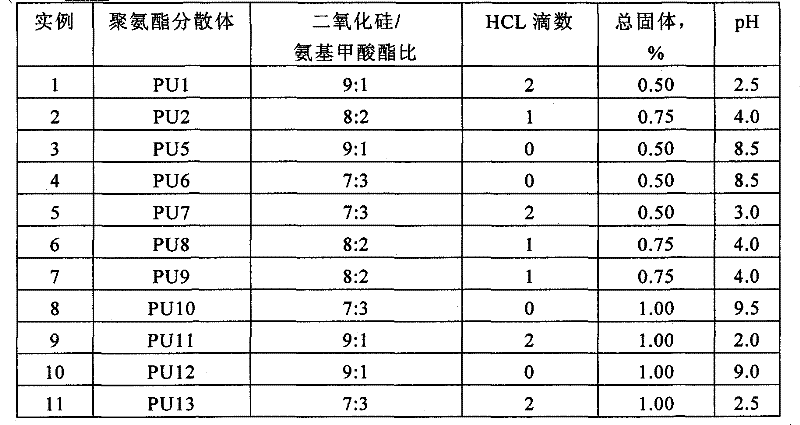

[0093] Example 2-11

[0094] Using a method similar to that described in Example 1, a 5.32% solid NPS1 masterbatch was prepared by manually mixing 30.013 g NPS1 and 66.014 g deionized water at 22°C until uniform. An aliquot of the 5.32% solids NPS1 masterbatch (approximately 6.4 g each) was combined with appropriate amounts of 4.5% solids polyurethane dispersions PU2 and PU5-PU13. As indicated in Table 1, a few drops of HCl were added to these mixtures, after which, each NPS:PU dispersion was subsequently diluted to a total solid content of 0.50 to 1.00%, and a silica: polyurethane ratio of 9:1 to 7:3. The compositions of Examples 1-11 are reported in Table 1 (below).

[0095] Table 1

[0096]

[0097] The 1 inch x 2 inch (2.54 x 5.08 cm (cm)) aluminum coupons of the test panels TP1, TP2 and TP3 were sprayed with ethanol and wiped dry before applying the test dispersion. During the coating process, place one drop of each test dispersion on the test plate, and then swab it with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Antenna | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap