Clip detecting system and detecting method

A detection system and detection method technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as time-consuming, laborious installation, wrong installation direction, and occupation of the total installation process, and achieve the effect of improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

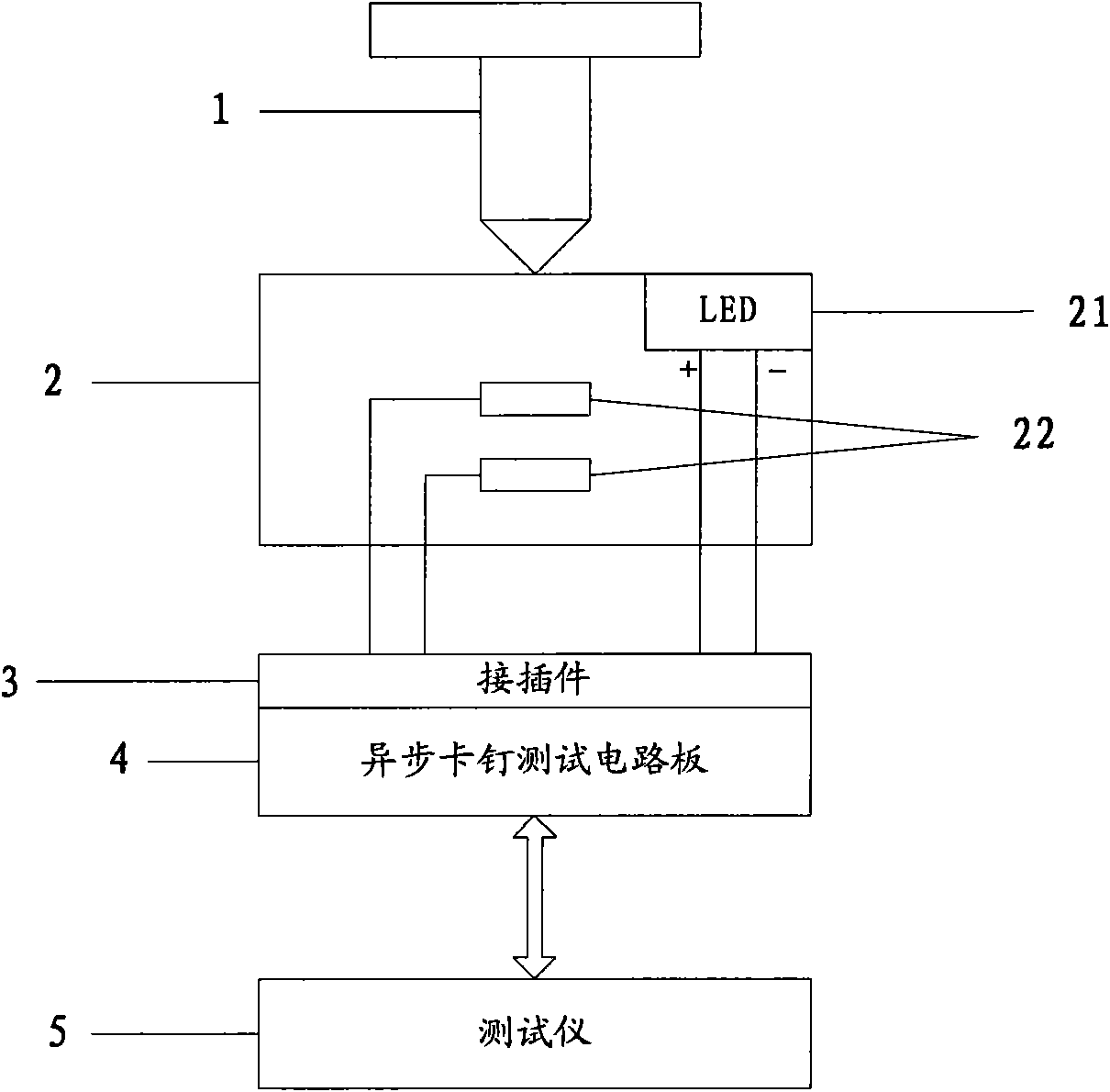

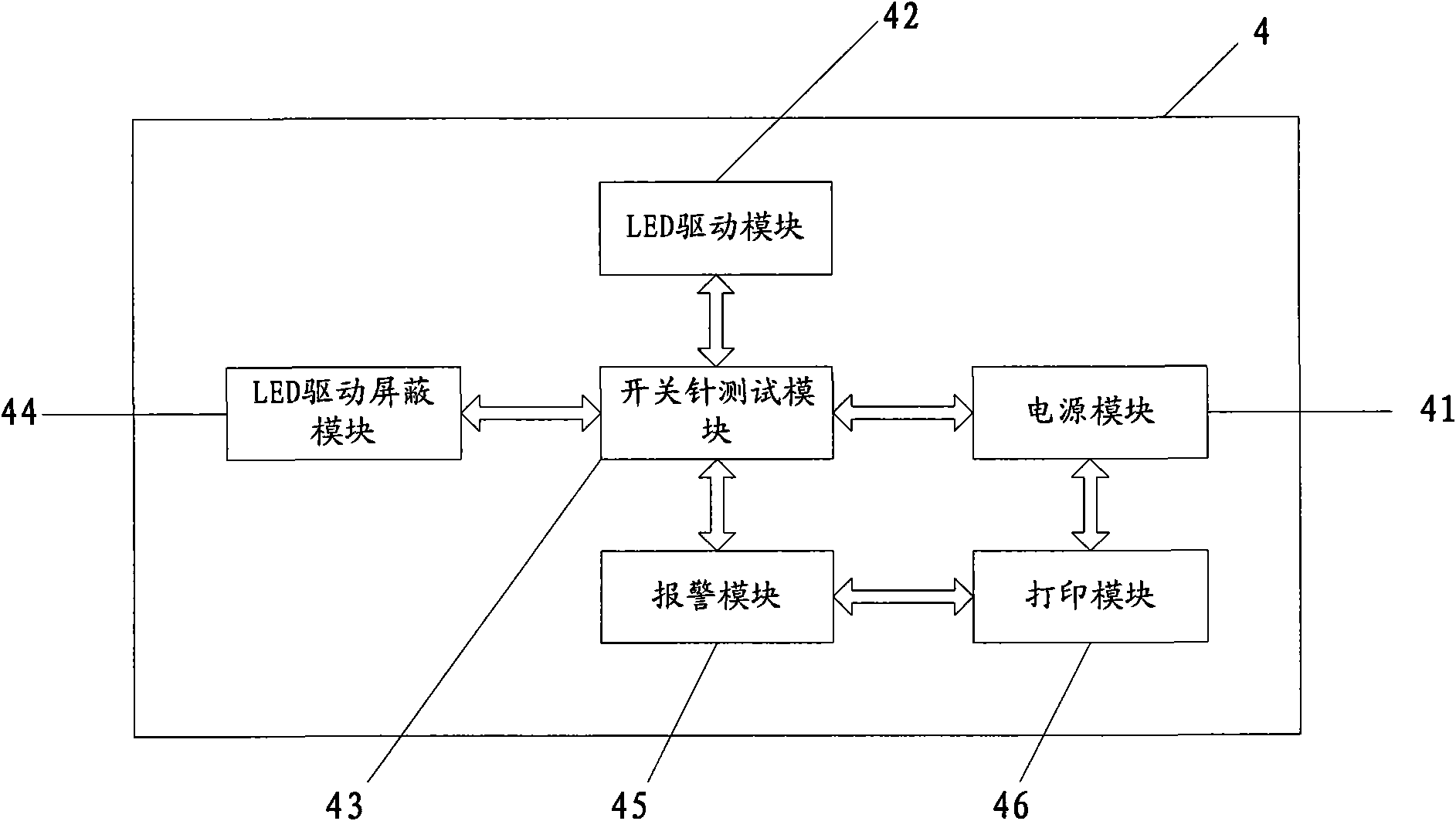

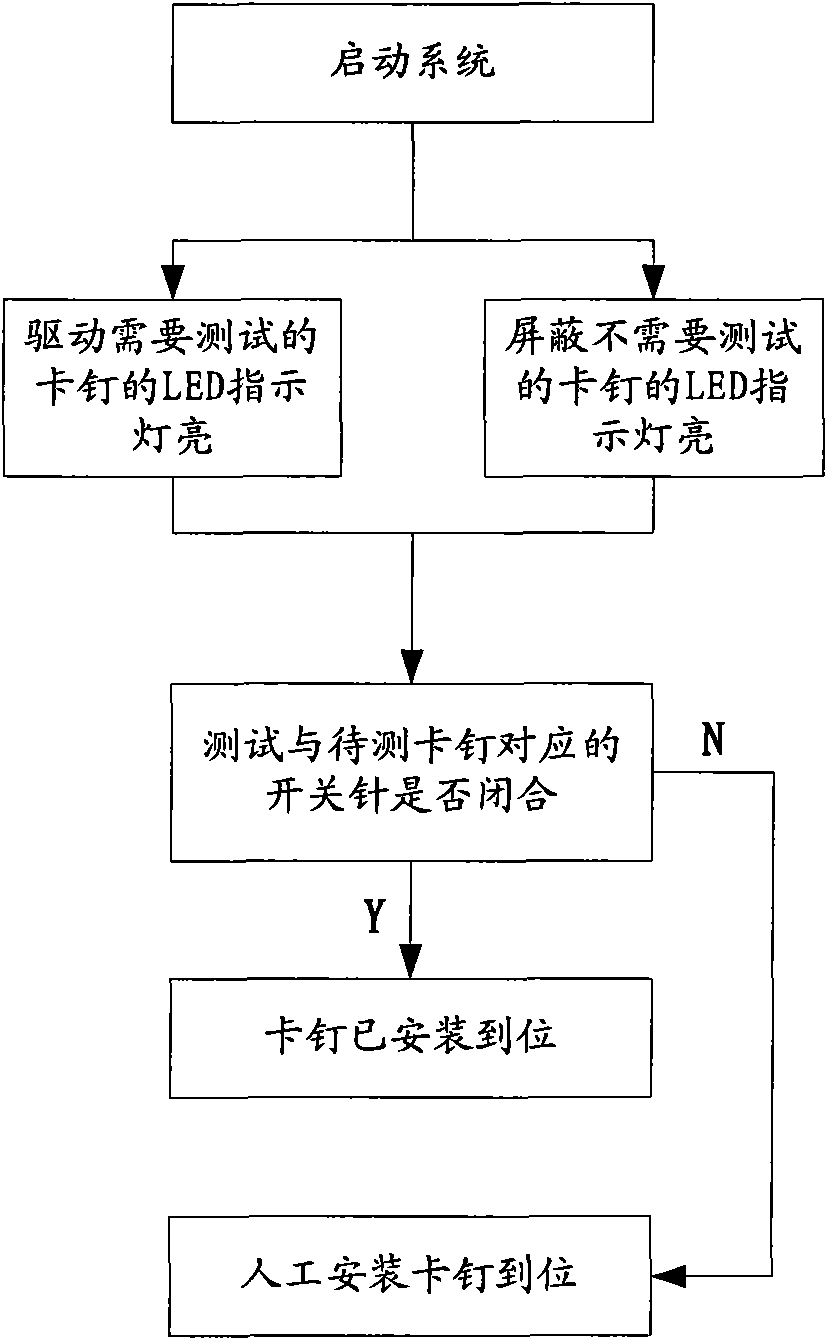

[0030] This embodiment provides a Clip detection system, such as figure 1 As shown, the detection system includes a staple 1 , an error-proof slot 2 , a connector 3 , an asynchronous staple test circuit board 4 , and a tester 5 . The staple 1 snaps into an anti-error slot 2 . The error prevention groove 2 is provided with LED 21 and switch pin 22, the LED pole leads out of the groove through a red wire, the LED negative pole leads out of the groove through a black wire, and the two ends of the switch needle 22 lead out of the groove through two non-red and black wires . The connector 3 is connected to the four lead wires of the error prevention slot 2 . The asynchronous staple test circuit board 4 is matched and plugged with the connector 3 to detect whether the staple 1 is correctly installed in the error prevention slot 2; the asynchronous staple test circuit board 4 is flattened by two 64-core The cable is connected with the tester 5 . The tester 5 is connected to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com