Formwork support tool for steel structure floor system and construction method for framework support tool

A formwork support and construction method technology, which is applied in formwork platform support and construction fields, can solve the problems of increased floor construction load, low bearing capacity of a single vertical pole, and uneven steel pipe materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

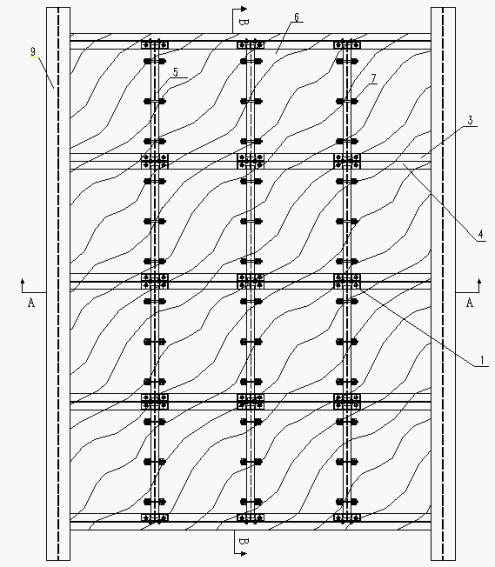

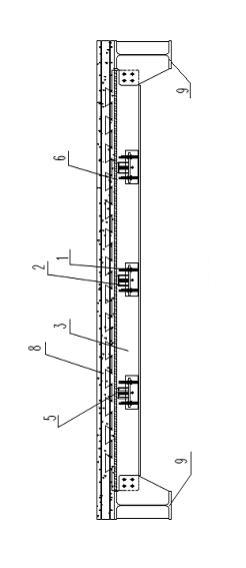

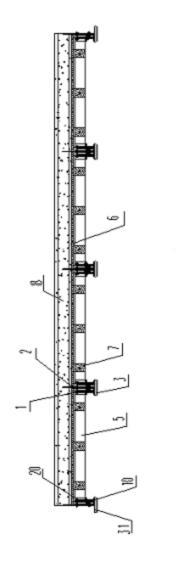

[0024] figure 1 According to the first embodiment of the present invention, a structural schematic diagram of a formwork support tool applied to steel structure floor construction is shown. Specifically, in this embodiment, as shown in the figure, in the construction of the steel structure floor formwork platform, in order to bind the wooden formwork 6, the construction personnel pass the main beam 9, the composite beam 3, the support frame 1 and the support section steel 5 to form the formwork. The platform is supported, and those skilled in the art understand that the two ends of the main beam rest on the room column ( figure 1 not shown in ), where there are several composite beams arranged at equal intervals between two adjacent main beams, specifically, as figure 1 The composite beam 3 shown as a secondary beam is supported on the two main beams, and the composite beam 3 and the main beam 9 form a vertical angle. Further, several formwork support tools are installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com