Internal cooling system of thyristor valve

A technology for cooling systems and thyristor valves, applied to electrical components, electrical solid devices, circuits, etc., can solve the problems of inaccurate parameter indicators and inability to combine actual system applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

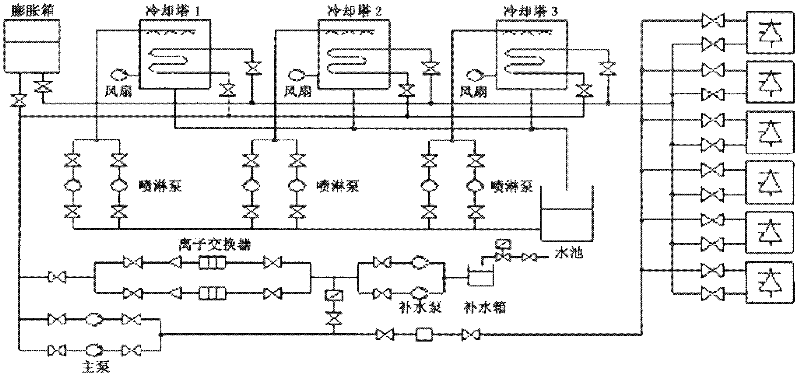

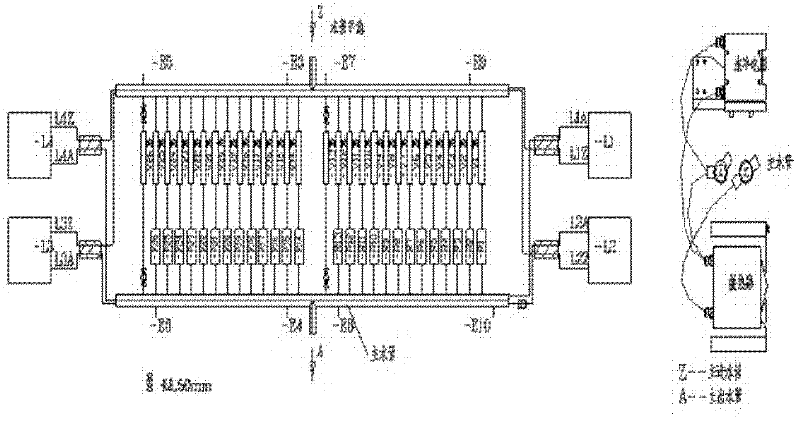

[0016] see figure 1 , the internal cooling system is a relatively complex system compared to the external cooling system. The thyristor converter valve in this project is an indoor suspended quadruple valve tower structure, so there are four valves in each quadruple valve tower unit , each quadruple valve tower is composed of 12 thyristor modules in 6 layers up and down, left and right. Each valve consists of three thyristor modules, and each thyristor module consists of two valve layers. Each valve layer is composed of 13 thyristor stages connected in parallel with the RC loop; and then connected in series with 4 reactors.

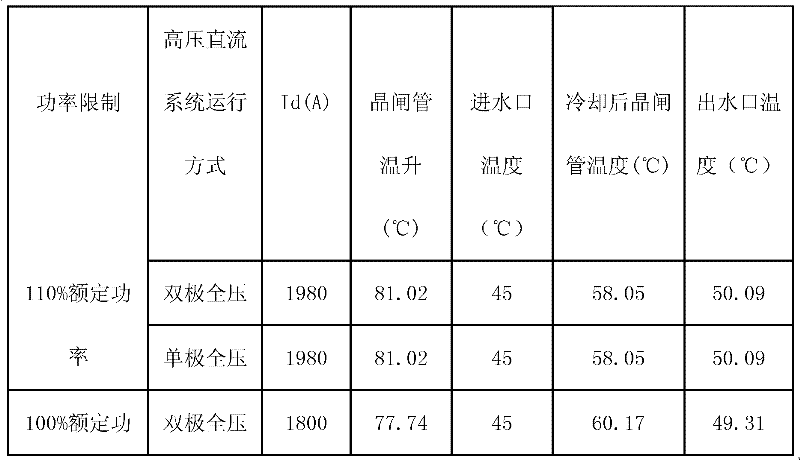

[0017] Thyristors, damping resistors and valve reactors are cooled with deionized water. Each valve tower has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com