Improved track cleaning structure of mobile shelf

A technology for cleaning structures and tracks, applied in railway car body parts, railway vehicle wheel guards/buffers, transportation and packaging, etc., can solve problems such as affecting the running of guide wheels, jamming, and easy entry of sundries into the recessed rails.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

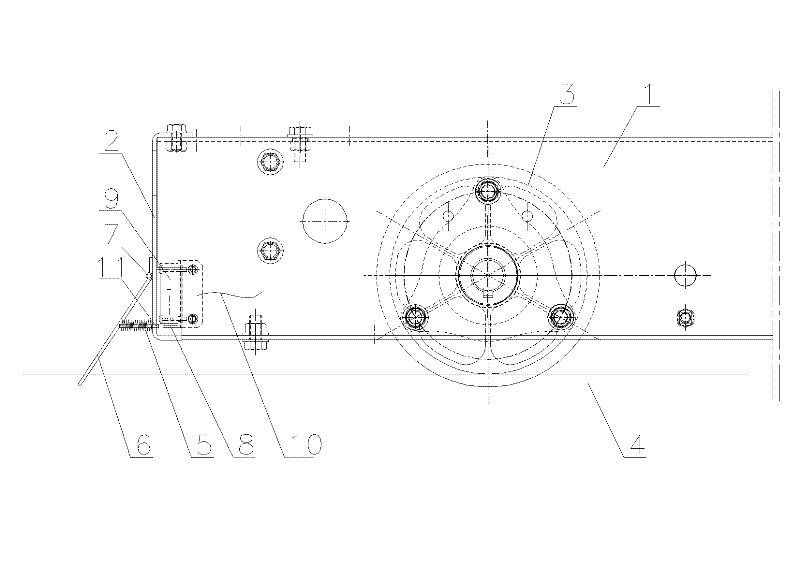

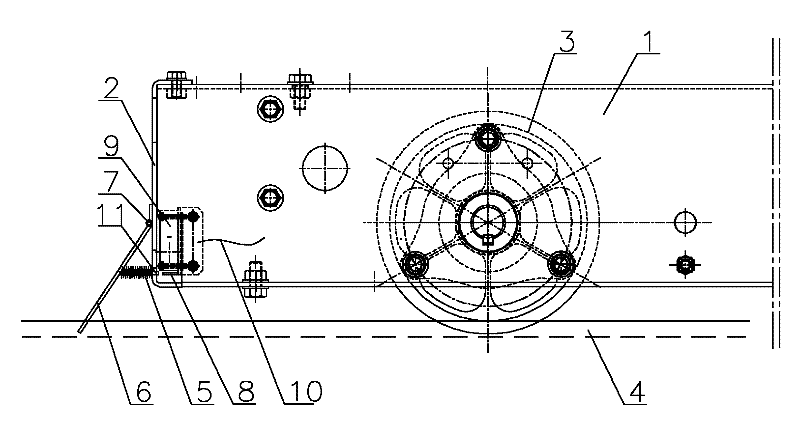

[0007] See figure 1 , which includes a floor column 1, a floor beam 2, a guide wheel 3 with convex ribs, and a concave rail 4. Rail 4, the outer side of the floor beam 2 at the front end of the guide wheel 3 with ribs is equipped with a cleaning fork plate 6, the lower part of the cleaning fork plate 6 goes deep into the concave rail 4, and the end of the cleaning fork plate 6 is fastened and connected by a hinge 7 The bottom beam 2, the middle part of the cleaning fork plate 6 and the bottom beam 2 are provided with a spring 5, the spring 5 is set on the pressure rod 11, the pressure rod 11 runs through the bottom beam 2, and the inner side of the bottom beam 2 is fastened with the sensor 9, the pressure rod 11 Towards the control switch 8 of the sensor 9, the wire 10 of the sensor 9 is connected to the motor (not shown in the figure, which belongs to the existing mature structure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com