Crude oil pipeline sampling head

A crude oil pipeline and sampling head technology, applied in sampling devices, pipeline systems, mechanical equipment, etc., can solve the problems of poor repeatability of single sampling amount, unrepresentative samples, and limited single sampling amount, etc. , the effect of increasing the level of sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

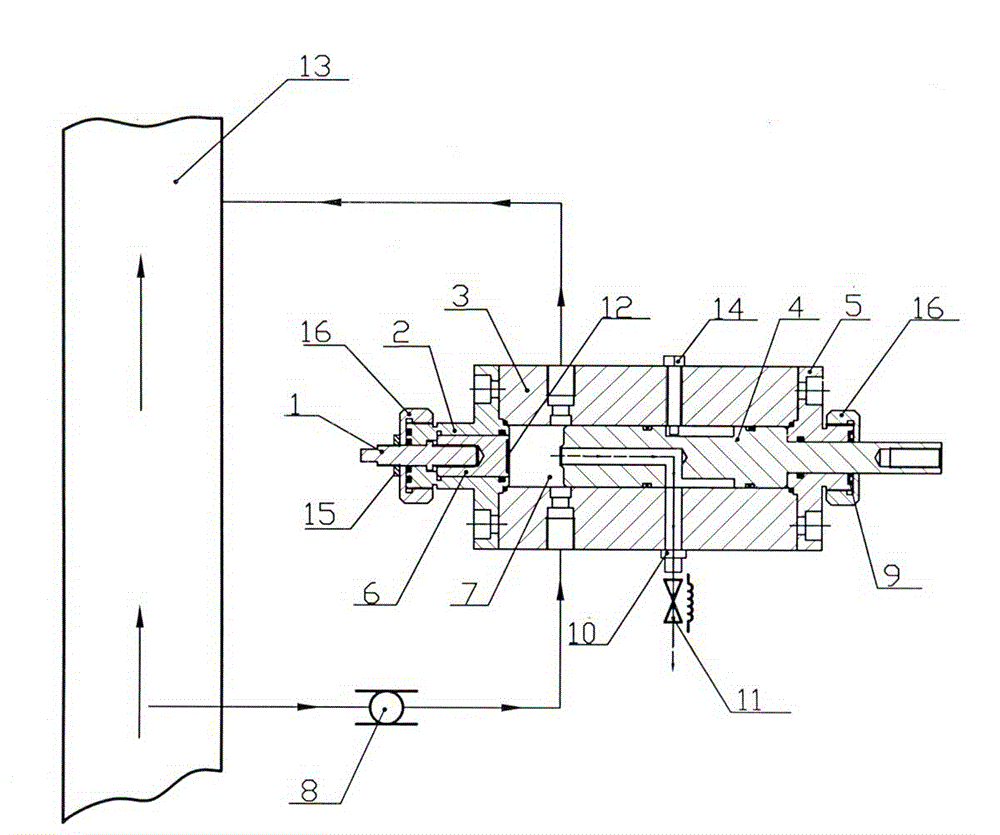

[0014] Referring to the accompanying drawings, the crude oil pipeline sampling head includes a cylinder body 3, a piston 4, a front end cover 5 and a rear end cover 2, the front end cover 5 and the rear end cover 2 are respectively installed at both ends of the cylinder body 3, and the piston 4 is installed in the cylinder body. The inner hole of the cylinder body 3 is tightly matched with the inner hole. The rod part of the piston 4 passes through the front end cover 5 and protrudes outside. The rod part of the piston 4 on the outside is used to connect with the reciprocating power; The oil inlet and the oil outlet communicated with the inner hole of the cylinder body 3; the outer surface of the piston 4 has a guide groove along the axial direction, and the side of the cylinder body 3 is provided with a threaded hole communicating with the inner hole, and the threaded hole is screwed with Guide bolt 14, the front end of guide bolt 14 is inserted in the guide groove; Piston 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com