LED (light-emitting diode) lamp with good heat dissipation

A LED lamp and heat dissipation technology, which is applied in the direction of lighting and heating equipment, parts of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problem of affecting the service life of LED lighting lamps, the difficulty of effectively dissipating heat, and affecting the normal operation of electronic components. Work and other problems, to avoid impact, reduce the temperature rise of the power supply environment, and effectively convective heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

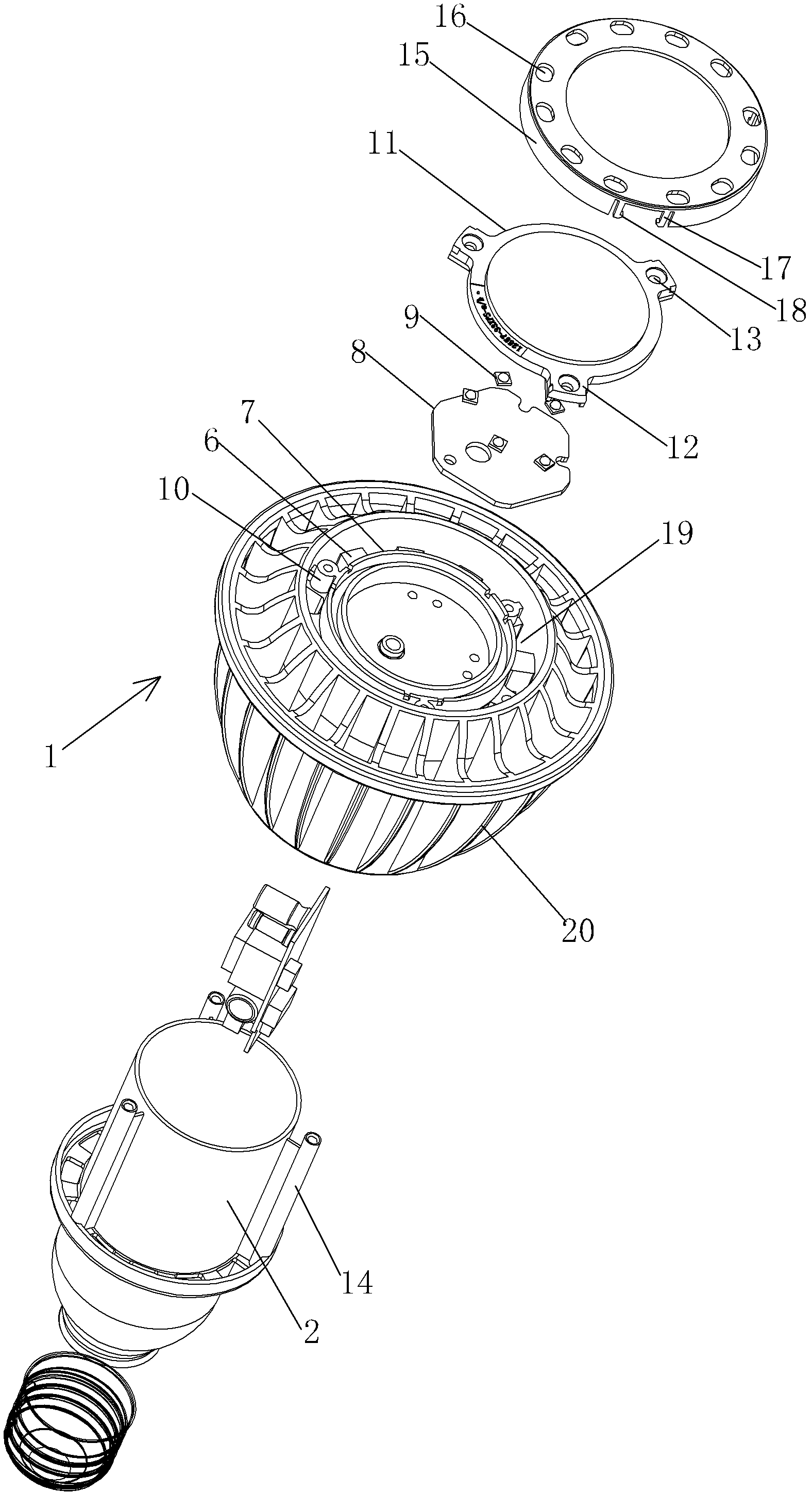

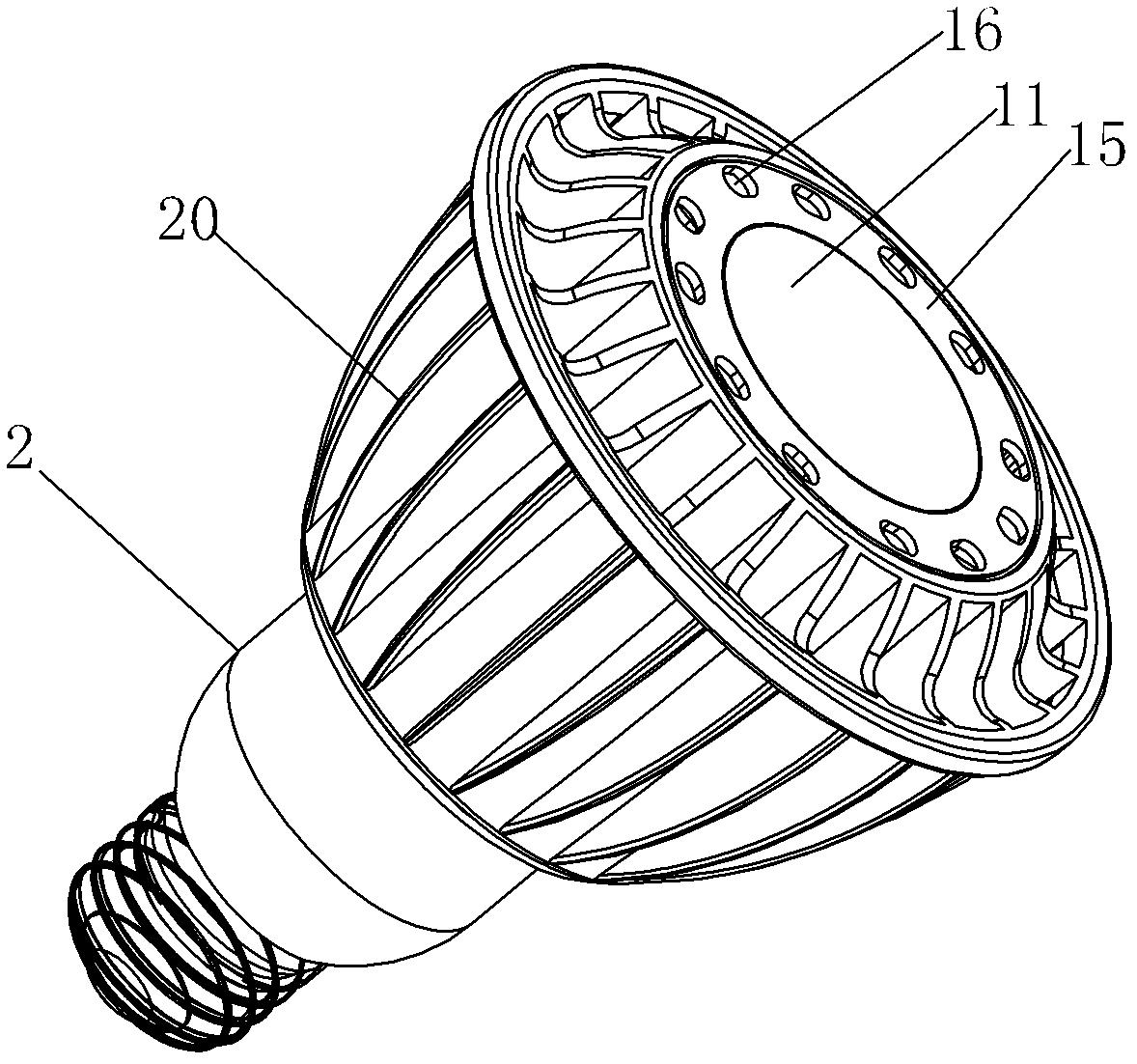

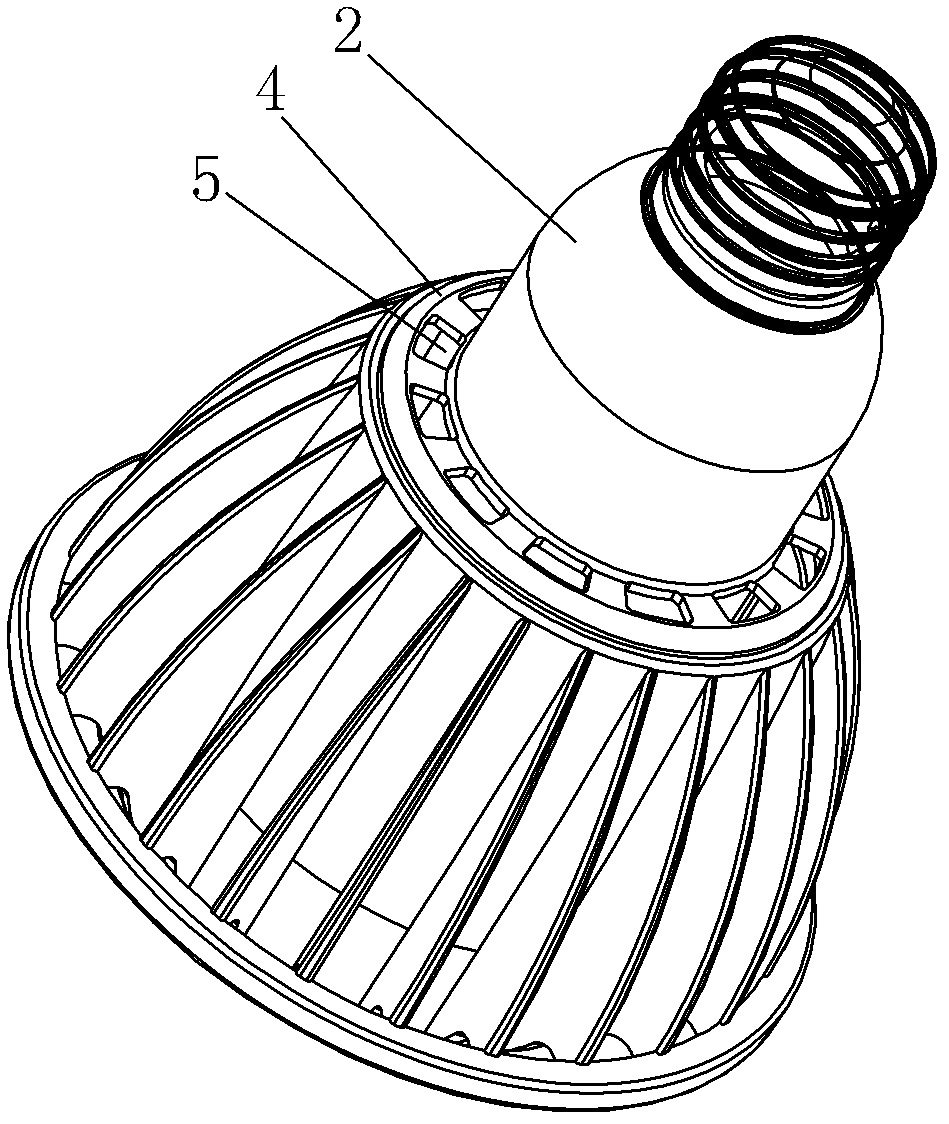

[0022] Embodiment: a kind of LED lamp with good heat dissipation of the present embodiment, such as Figure 1~4 As shown, it includes a heat dissipation lamp cup 1 and a driving power supply housing 2. The interior of the heat dissipation lamp cup 1 is hollow and has openings at both ends. A plurality of heat dissipation fins 20 are distributed on the outer circumference of the heat dissipation lamp cup 1 along the circumferential direction. The cup 1 is nested with the drive power supply housing 2 , and a heat dissipation channel vertically penetrating the openings at both ends of the heat dissipation lamp cup 1 is formed between the drive power supply housing 2 and the heat dissipation lamp cup 1 .

[0023] The heat dissipation channel is formed as follows:

[0024] The outer diameter of the driving power housing 2 is smaller than the inner diameter of the heat dissipation lamp cup 1, and the outer wall of the driving power housing 2 is protruded with a rib 14 for limiting i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com