Boost grouping method of storage battery module and boost grouping controller of storage battery module

A technology for battery modules and battery packs, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve problems such as impact, easy overcharge or overdischarge of batteries, poor consistency of technical indicators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiment of the present invention is described below with accompanying drawing as example:

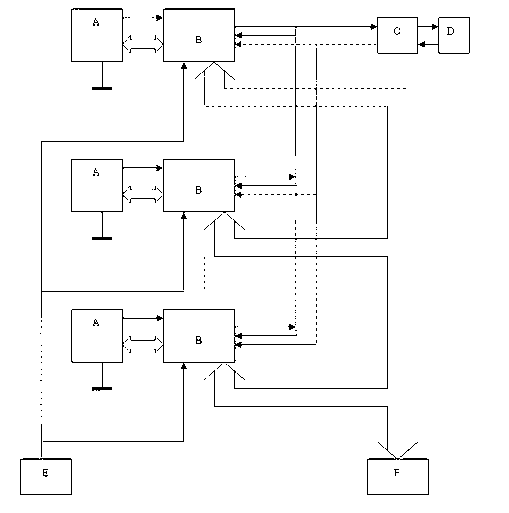

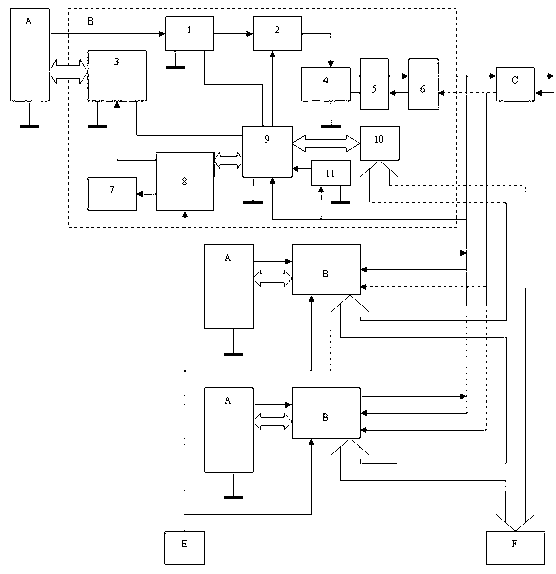

[0019] Fig. 1 is an electrical schematic diagram of the system configuration of a battery module step-up group controller according to an embodiment of the present invention, wherein:

[0020] A is the battery module, which can be formed by connecting conventional single batteries in series; B is the charging and discharging boost controller of the battery module, and its circuit composition principle is shown in Figure 2; C is a supercapacitor, which uses a large-capacity capacitor And the withstand voltage can match the output voltage; D is the load; E is the charging input power supply, and the charging input power supply whose output is consistent with the charging index of each battery module can be used; the current input and output terminals of each battery module are respectively connected to a The low-voltage input and output terminals of the battery module charge and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com