Vehicle lighting device supporting structure

A lighting device, vehicle technology, applied in bicycle accessories, transportation and packaging, optical signals, etc., to achieve the effect of improving appearance, simple supporting structure, and reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] First, Embodiment 1 of the present invention will be described with reference to the drawings.

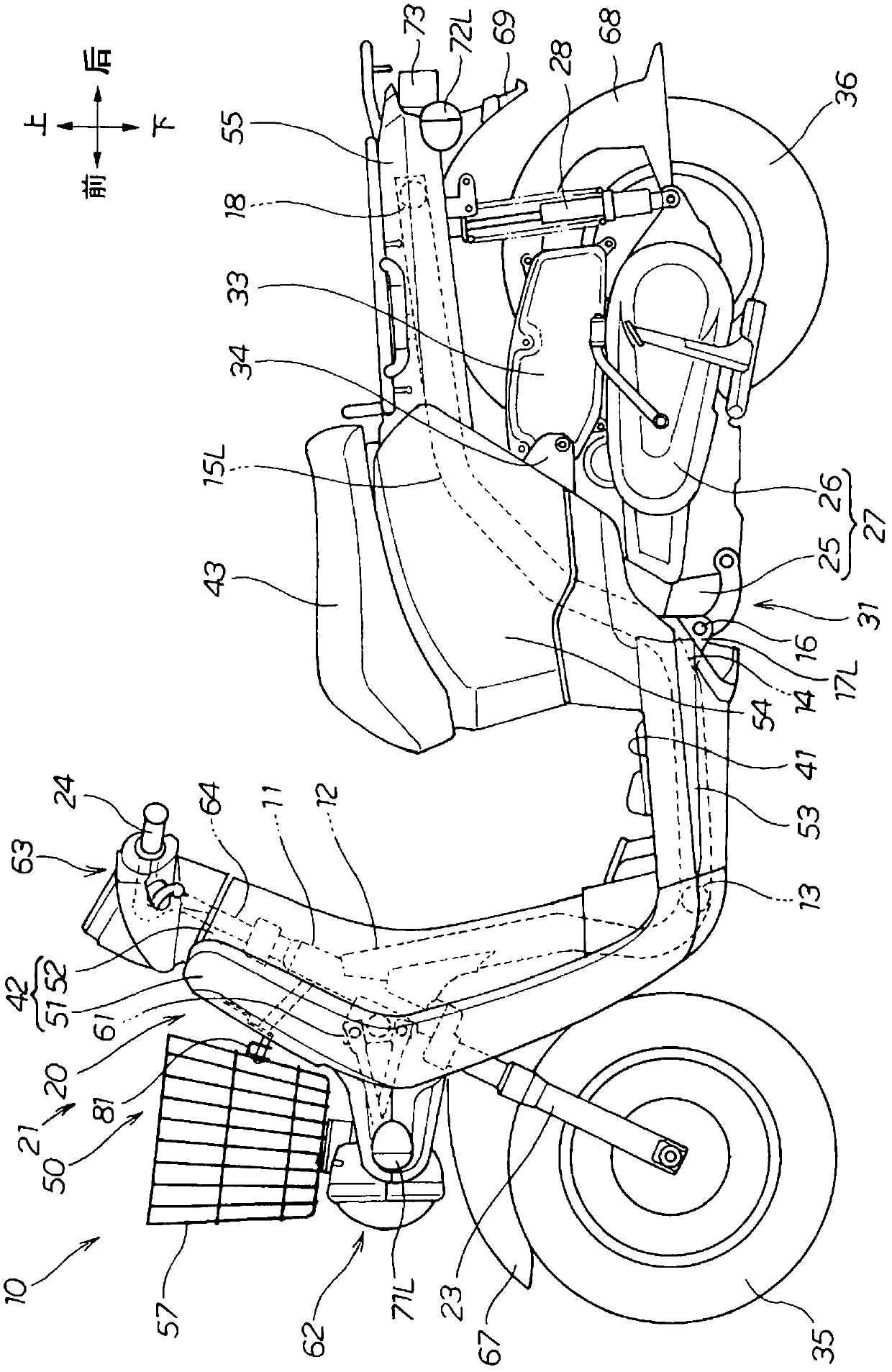

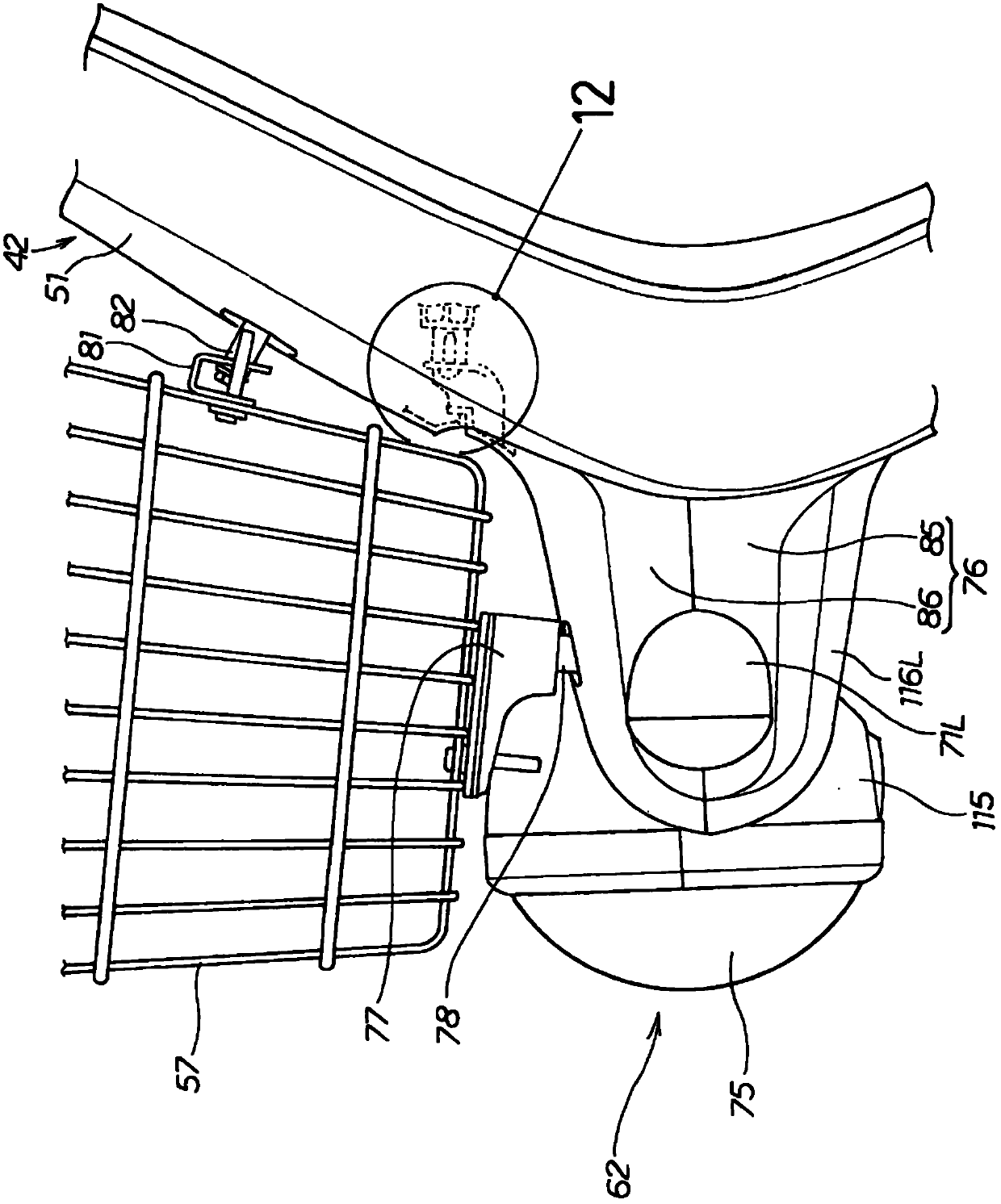

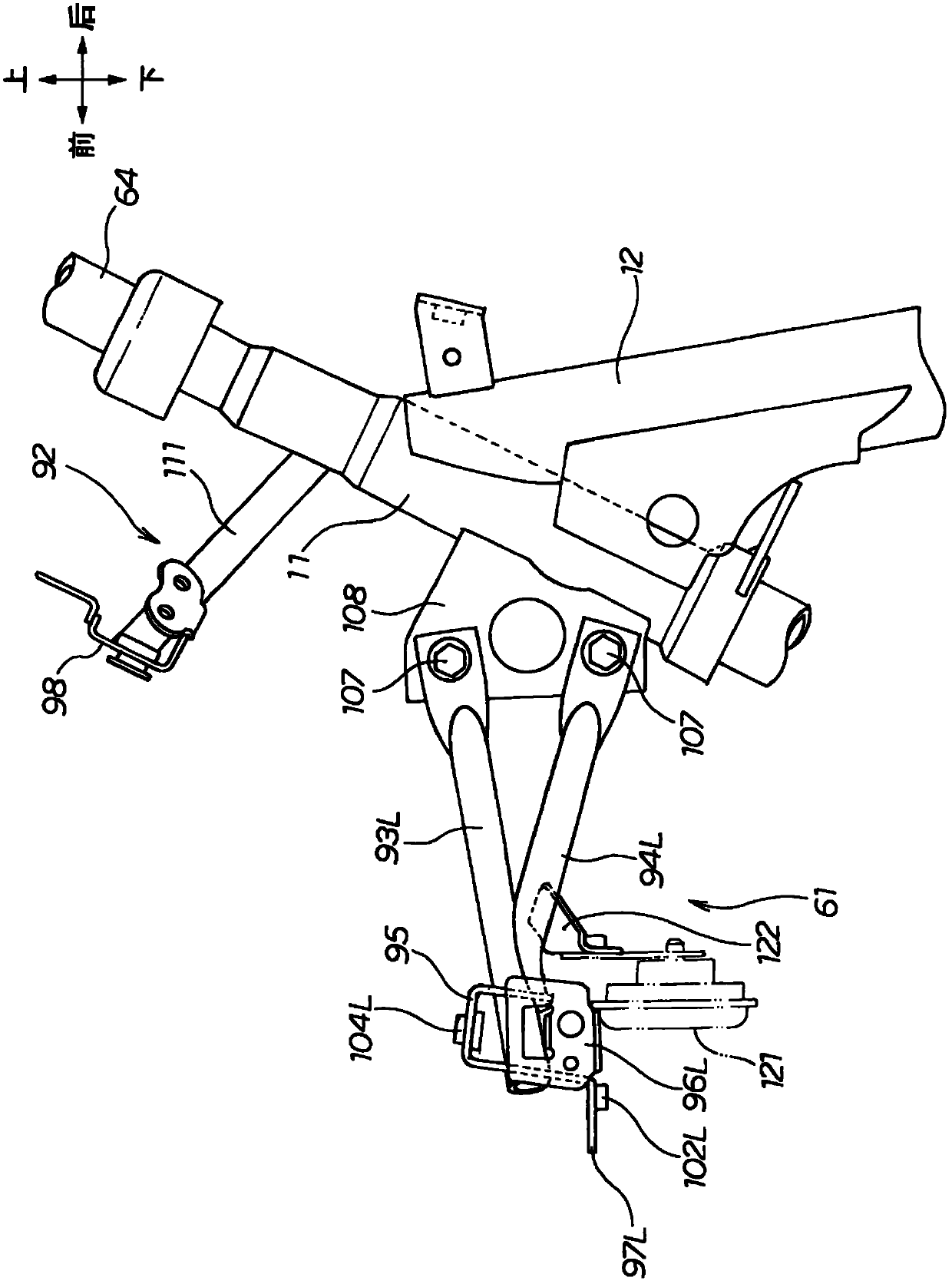

[0051] Such as figure 1 As shown, a vehicle frame 20 is provided on the motorcycle 10, and the main components of the vehicle frame 20 are: a head pipe 11, a main frame 12 extending obliquely from the head pipe 11 toward the rear, and a main frame 12 on the main frame 12. The rear end portion of the front cross frame 13 extending in the vehicle width direction extends from the head pipe 11 toward the left and right outwards in the vehicle width direction, is connected to the left and right ends of the front cross frame 13 and then extends toward the rear of the vehicle, and at the middle portion 14 toward the vehicle. The left and right side frames 15L, 15R (only the reference numeral 15L on the front side in the drawing) extending obliquely upward from the rear and extending horizontally toward the rear of the vehicle are attached to the middle part 14 and erect the pivot s...

Embodiment 2

[0132] Embodiment 2 of the present invention will be described below with reference to the drawings.

[0133] Such as Figure 13 As shown, the upper illuminator cover 86B is integrally formed with the front cover 51B. Therefore, the number of parts can be reduced as compared with the case where the upper lighting device cover and the front cover are constituted by separately formed single parts.

Embodiment 3

[0135] Embodiment 3 of the present invention will be described below with reference to the drawings.

[0136] Such as Figure 14 As shown, the front cover 51C is divided into a front cover upper half 181 and a front cover lower half 182, the front cover upper half 181 is integrated with the upper side lighting device cover 86C, and the front cover lower half 182 is connected with the lower side lighting device The cover 85C is integrally formed.

[0137] Therefore, the number of parts can be reduced as compared with the case where the front cover upper half and the upper side lighting device cover are composed of separately formed single parts.

[0138] In addition, the front cover lower half 182 is integrally formed with the lower lighting device cover 85C. Therefore, the number of parts can be reduced as compared with the case where the front cover lower half and the lower lighting device cover are composed of separately formed single parts.

[0139] In addition, in the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com