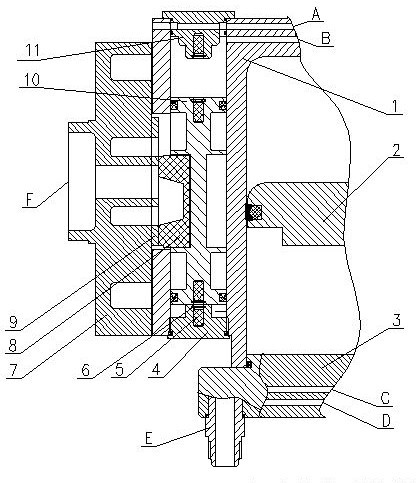

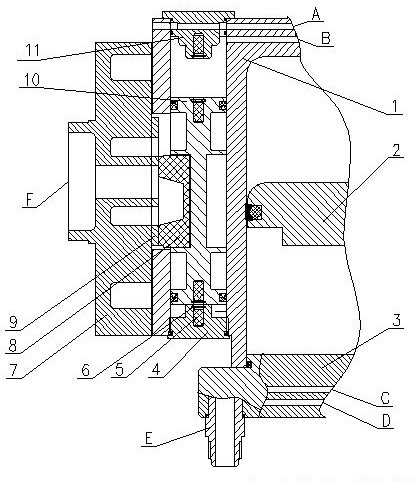

Pneumatic two-position four-way reversing valve

A two-position four-way, reversing valve technology, used in multi-way valves, valve details, valve devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] E is the main intake port of compressed air. Compressed air enters the lower chamber or upper chamber of the cylinder through the air distribution block 7. The upper and lower chambers of the reversing piston 10 enter the compressed air at the same time. The cylinder piston 2 pushes the cylinder piston 2 under the action of compressed air. Movement up or down. When moving to the upper end, the cylinder piston pushes the pilot valve to work, and the compressed air in the upper chamber of the reversing piston 10 passes through the air inlet B of the upper pilot valve and then to the exhaust hole A of the upper pilot valve to communicate with the atmosphere. The 10 lower chambers are always connected with compressed air, and the reversing piston 10 is subjected to two forces simultaneously, compressed air force and magnetic force. When the compressed air is greater than the magnetic force, pushing the reversing piston 10 drives the slider 8 to move upward. With the change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com