Catalyst random packing

A technology of random packing and catalyst, which is applied in chemical instruments and methods, chemical/physical process, chemical/physical/physical-chemical process, etc., can solve the problems of catalyst and packing shell being difficult to suspend and fix, complicated to manufacture, and unable to transfer mass. , to achieve the effect of improving gas-liquid mass transfer efficiency and catalytic reaction conversion rate, overcoming gas short circuit, and simple filling operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

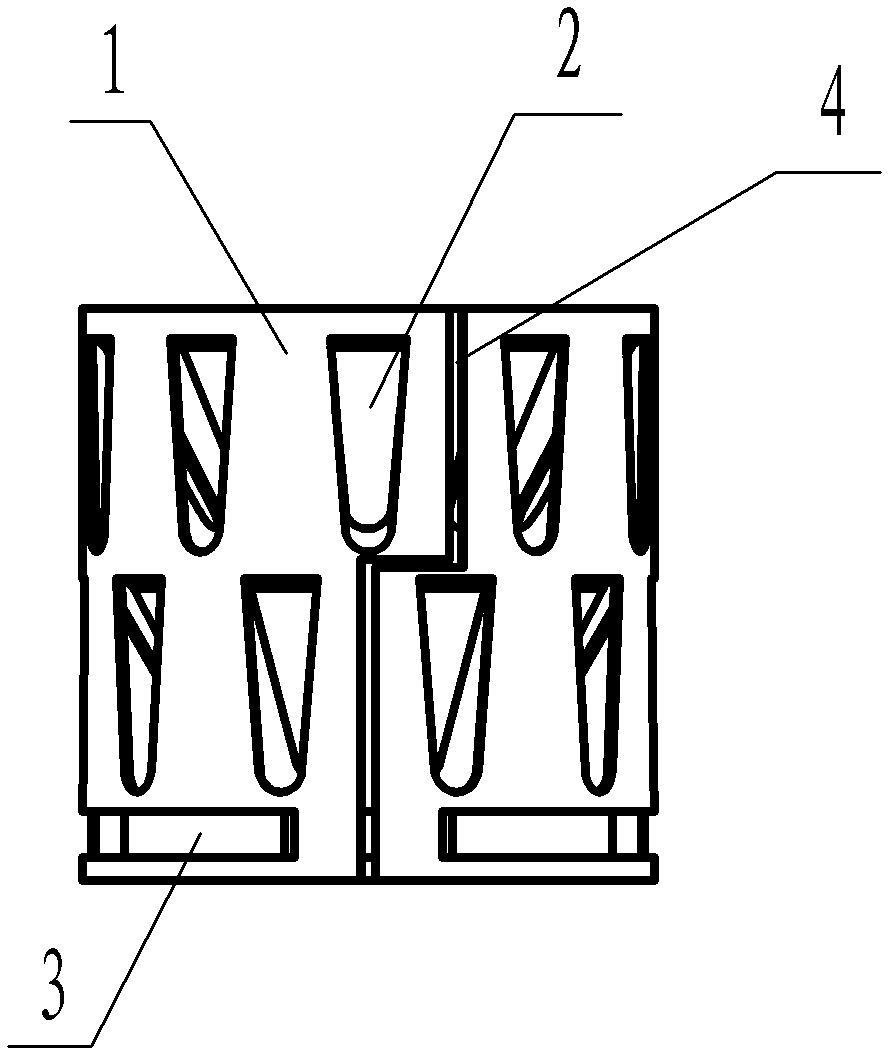

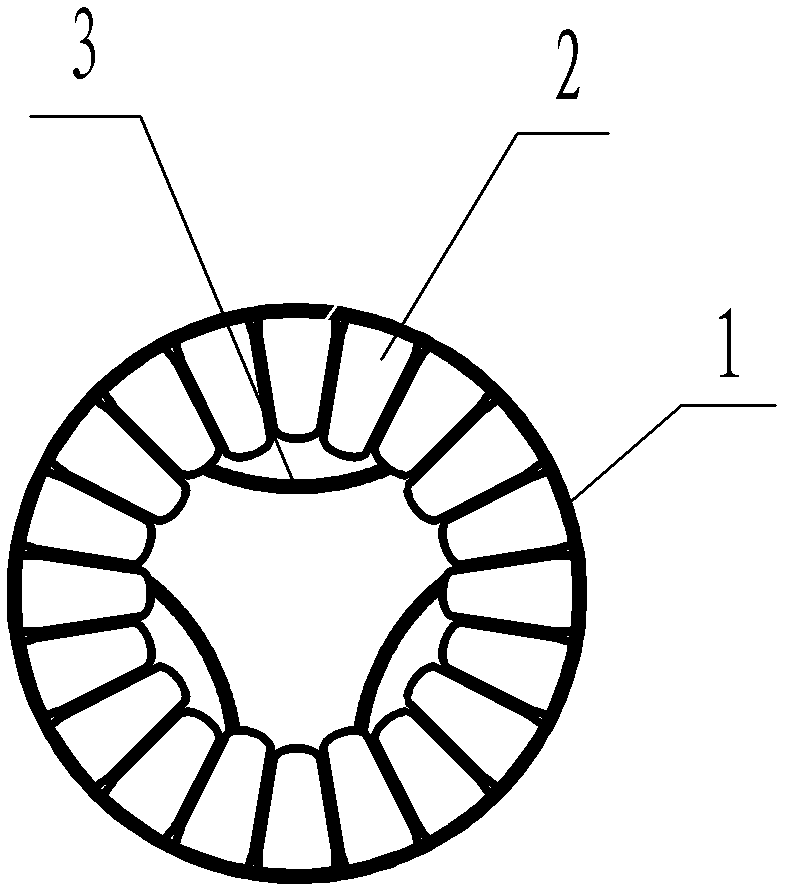

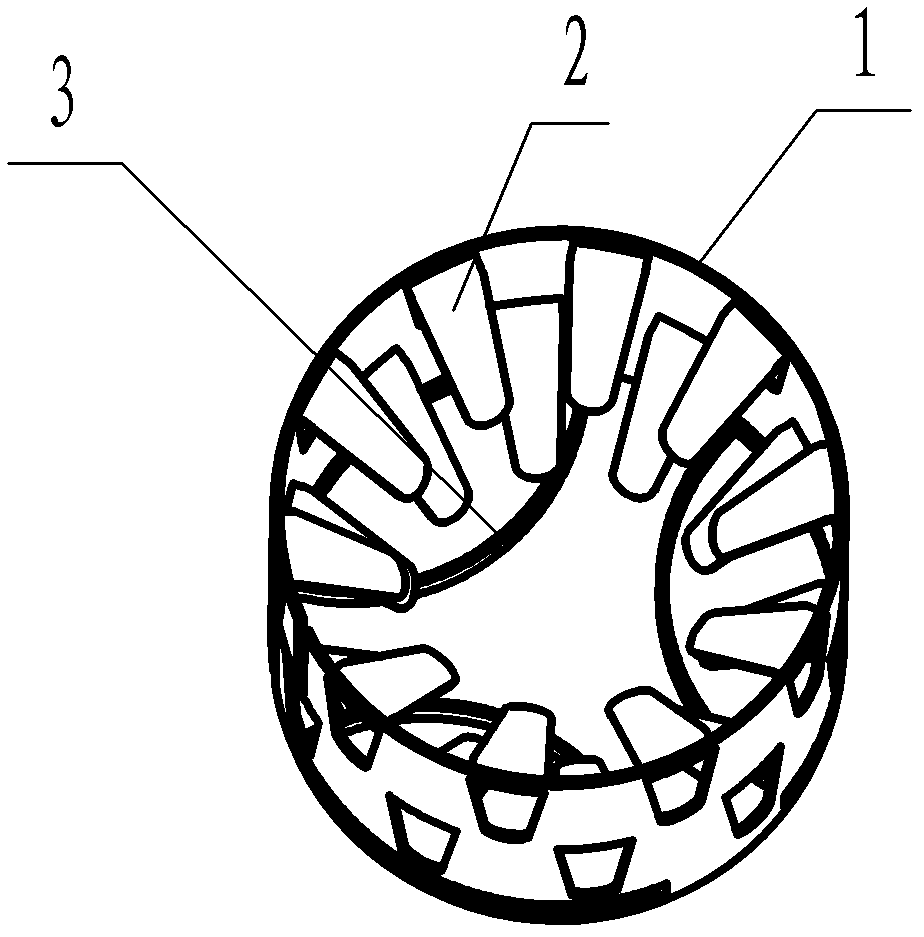

[0022] see Figure 1~3 , it has a packing shell and a catalyst package placed in the packing shell (the catalyst package is not shown in the figure), the packing shell has a cylinder 1, and a grid end is provided at one end of the cylinder For the cover, at least a circle of inner oblique tongue pieces 2 arranged uniformly along the circumference of the cylinder wall is provided on the cylinder wall of the cylinder body. The direction of the end cap, thus forming a bag barb; the axis of the inner latch tongue has an angle with the cylinder wall, and the angle can be adjusted between greater than 0° and less than 90°, so that the inner latch tongue The sheet has good elasticity. In order to make the packing better in gas-liquid contact, the inner oblique tongue piece 2 is provided with two or more turns along the axial direction of the cylinder wall. The oblique tongue pieces are misaligned. The cylinder body 1 can be formed by curling a piece of metal plate, the inner obliq...

Embodiment 2

[0025] In this example, on the basis of the structure of Example 1, the grid end cover adopts another structural form of one-piece end cover. Formed towards the tongue 5. This lattice end cover is also suitable for direct cutting and die stamping on the plate of the curled cylinder, and also has the advantage of simple manufacture. The other structures of this example are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com