Method for constructing steel-structure sand-blocking dam and steel-structure sand-blocking dam

A construction method and technology of steel structure, applied in construction, water conservancy engineering, marine engineering and other directions, can solve the problems of reducing the number of straws, low operation efficiency, short service life of straw rings, etc., and achieve easy processing and implementation, high processing speed. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

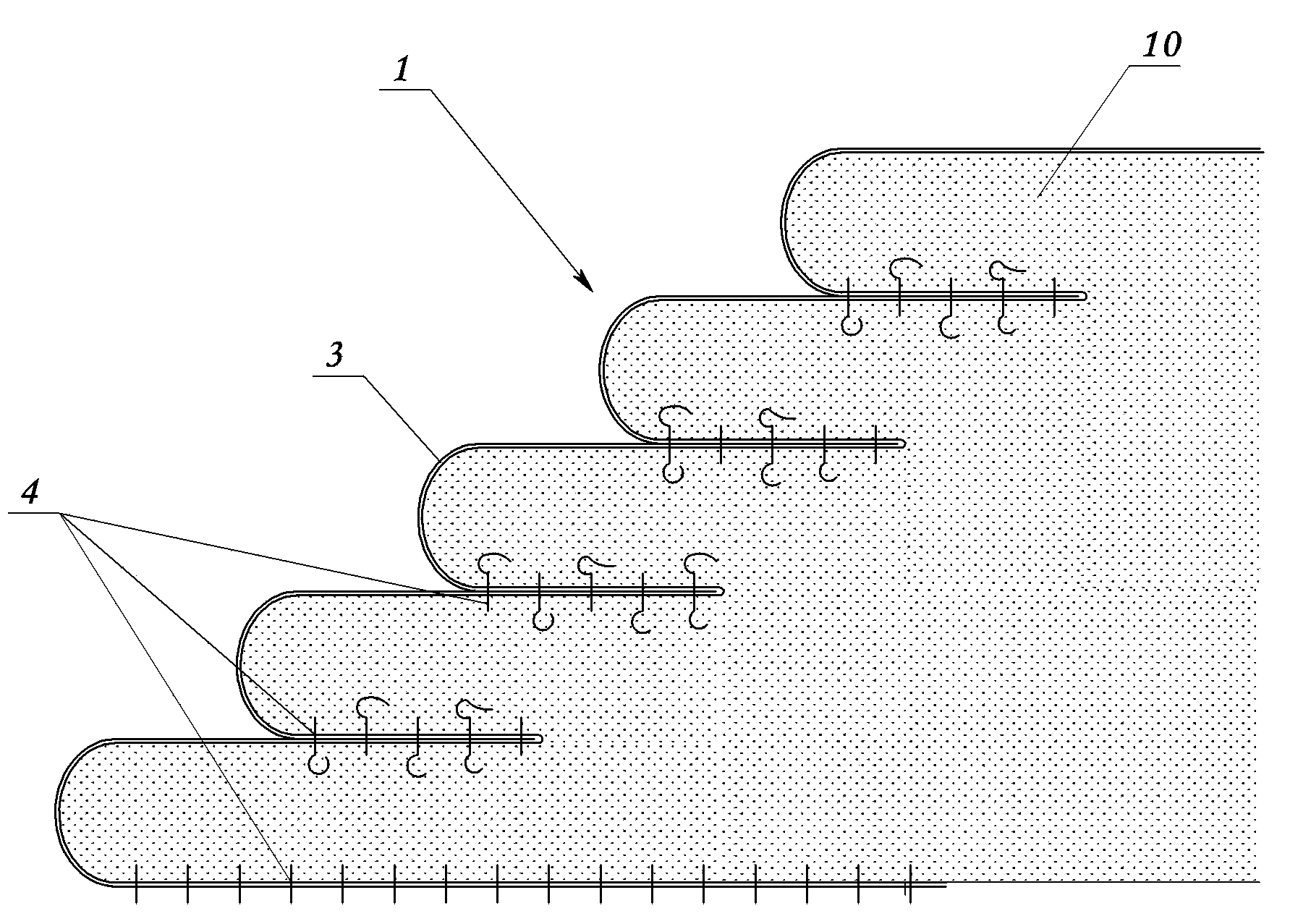

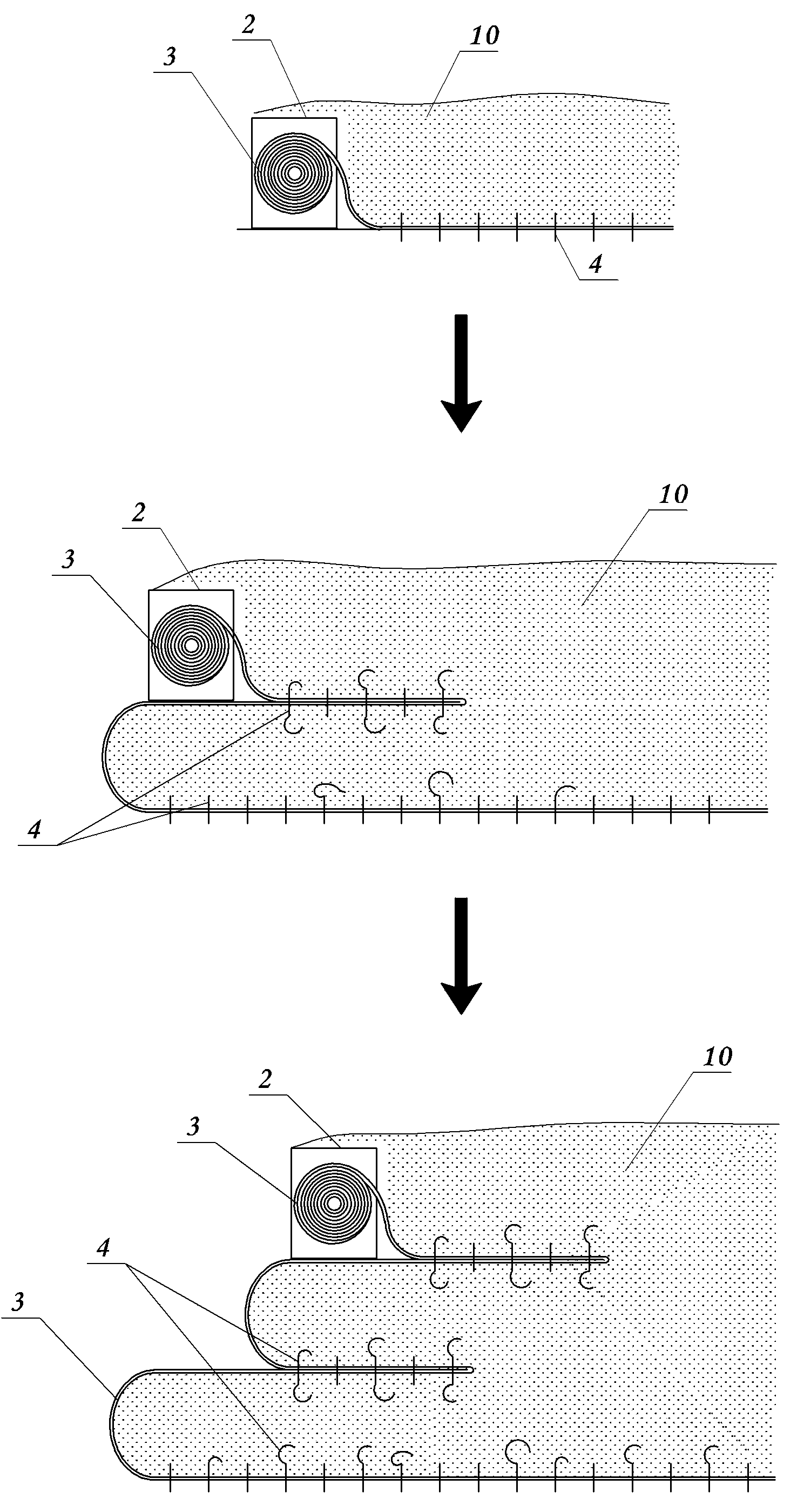

[0029] Embodiment one: see figure 1 with image 3 , a construction method of a steel structure sand-blocking dam, comprising the following steps:

[0030] (1) After cleaning the sand in the defensive area, spread the geomembrane 3 on the ground surface and fix it with the fixing piece 4, and keep the other end of the geomembrane in a roll for later use;

[0031] (2) The truss structure is used to form the sand-blocking support 2, and the geomembrane is covered on the sand-facing surface and the upper side of the sand-blocking support;

[0032] (3) While waiting for the natural flow of sand to level the height of the sand-blocking support, level the sand body behind the sand-blocking support, spread the spare geomembrane roll along the sand-facing surface to a certain width, and make it wrap the sand into a closed On top of this, lay a geomembrane in the opposite direction and save it as a roll to form the first layer of the sand-blocking dam; at the same time, set multiple f...

Embodiment 2

[0037] Embodiment two: see figure 1 with image 3 , content is basically the same as embodiment one, and similarity is not repeated, and difference is: when arranging the height of the sand body on the rear side of the sand-blocking layer, now carry out the compaction work of the sand body on this side.

Embodiment 3

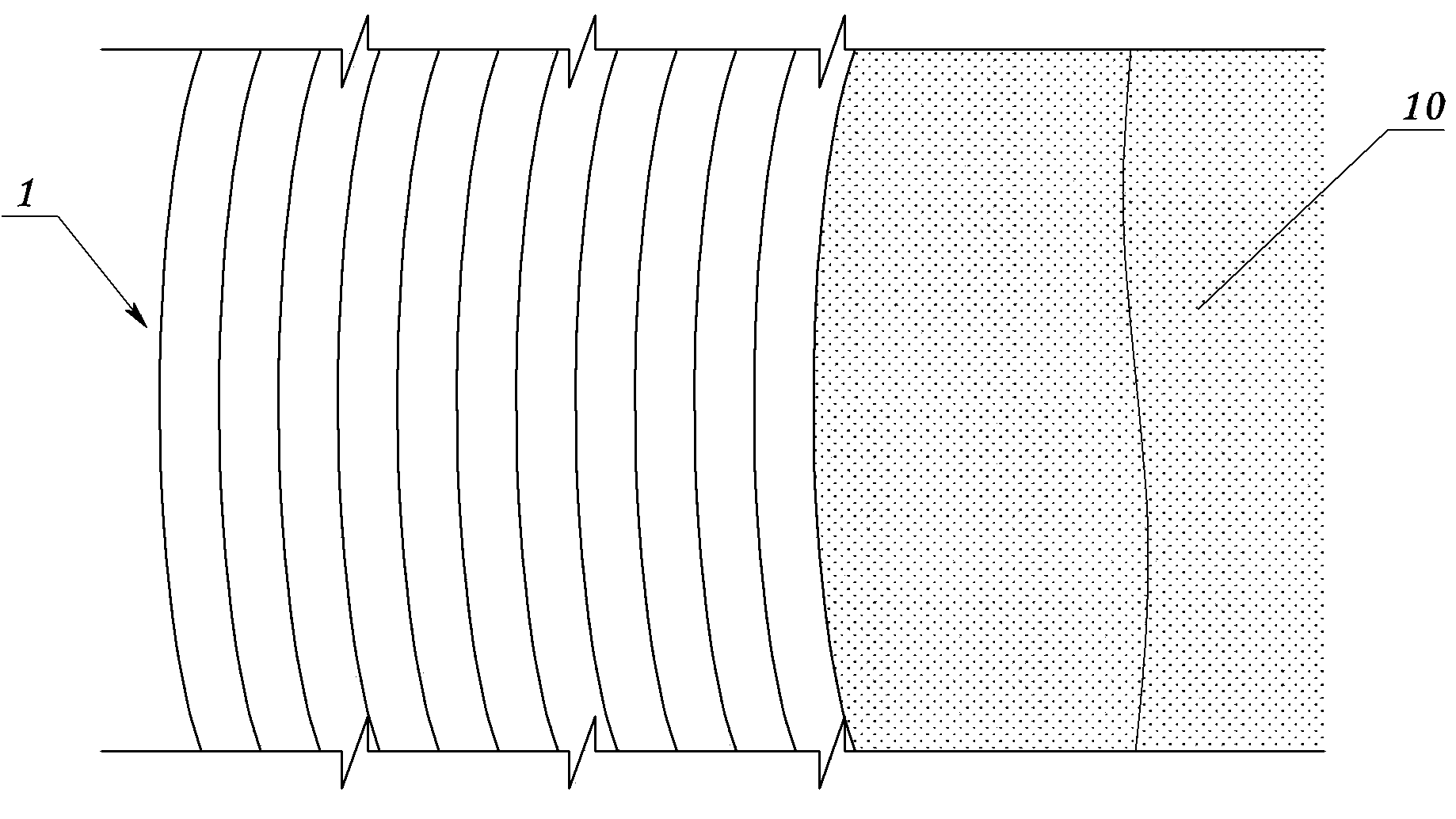

[0038] Embodiment three: see figure 1 , figure 2 with image 3 , content is basically the same as embodiment one, and similarity is not repeated, and difference is: the back sand surface of sand-blocking dam 1 is constructed into an arc, and the convex arc surface of the arc points to the back sand surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com