Patents

Literature

62results about How to "Reduce Reuse Costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for recovering waste acid in producing titanium white powder by sulfuric acid method

InactiveCN1381398AImprove filtering effectInhibitionSulfur-trioxide/sulfuric-acidTitanium dioxideAcid concentrationWhite powder

A process for recovering the waste acid in producing titanium oxide powder by the sulfuric acid method features use of gas-liquid separation type non-volatile solution concentrating apparatus. It includes such steps as depositing the waste acid to receiver solid Ti, pre-concentrating at 50-60 deg.C until acid concentration is 40-50%, filtering, and concentrating at 65-75 deg.C until its concentration reaches more than 70%.

Owner:吉林市吉研高新技术开发公司 +1

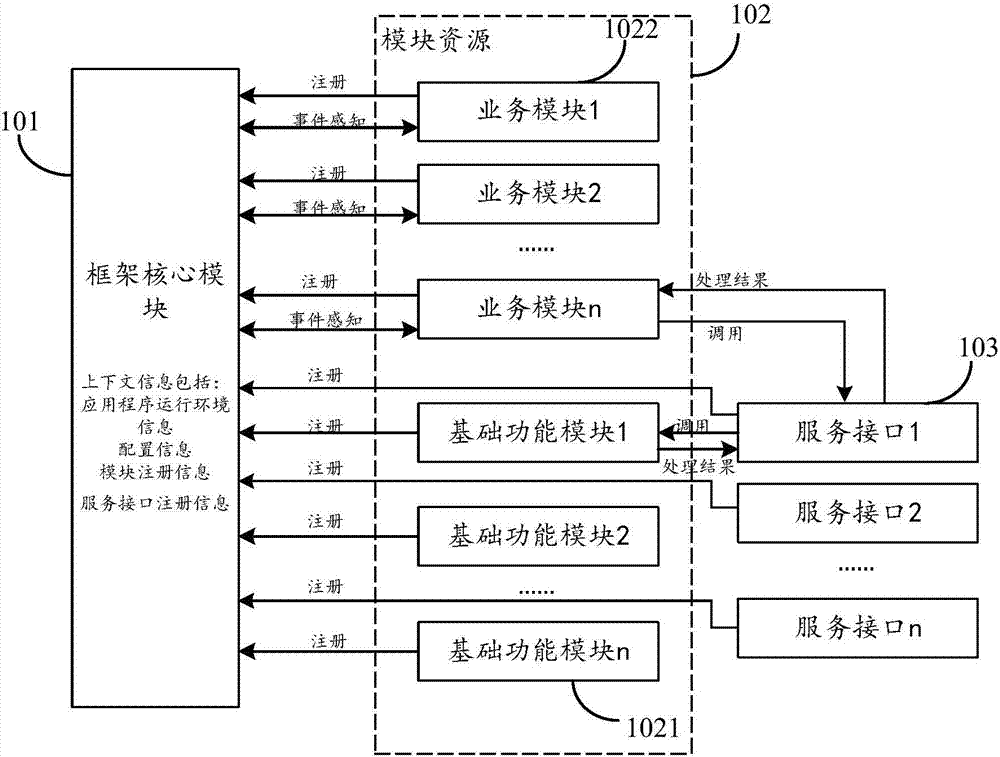

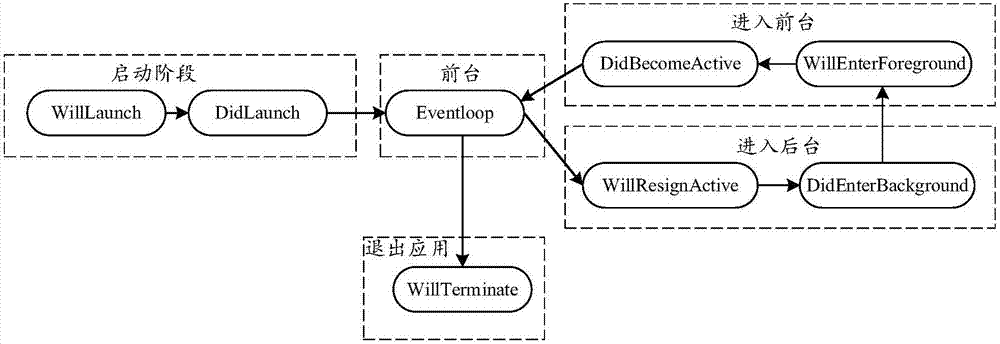

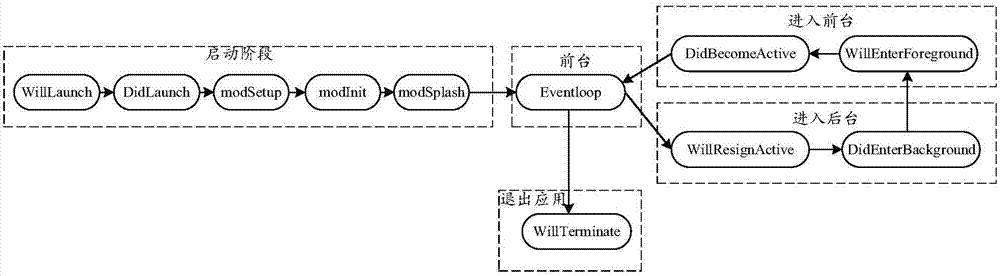

Inter-module calling method, device and system in application program

ActiveCN107203419AReduce Reuse CostsIncrease flexibilityProgram initiation/switchingComputer moduleSoftware engineering

The embodiment of the invention discloses an inter-module calling method, device and system in an application program. The system comprises a frame core module, a service module and a service interface, wherein the frame core module is used for maintaining contextual information related to the application program and providing an event perceptual interface; the contextual information is used for sharing various module resources; the service module is used for performing event perception through the event perceptual interface of the frame core module and initiating a calling request for the service interface corresponding to a target event when the target event is perceived; the service interface is used for calling a corresponding basic function module according to the calling request of the service module, transmitting parameters in the calling request to the basic function module, and returning a processing result to the service module after receiving the processing result returned back by the basic function module. According to the inter-module calling method, device and system in the application program, the reuse cost of the modules can be lowered, and the flexibility of the modules is improved.

Owner:ALIBABA GRP HLDG LTD

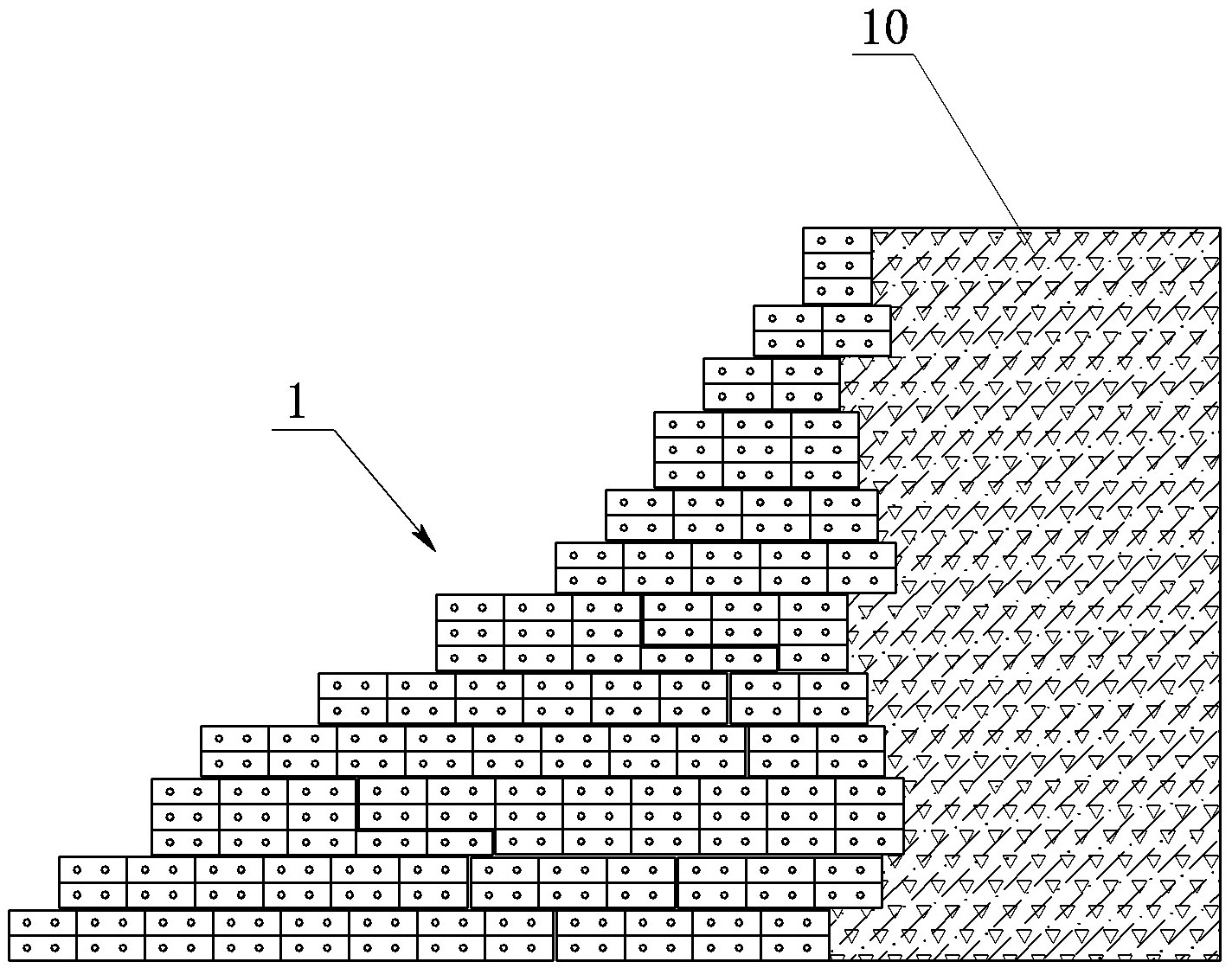

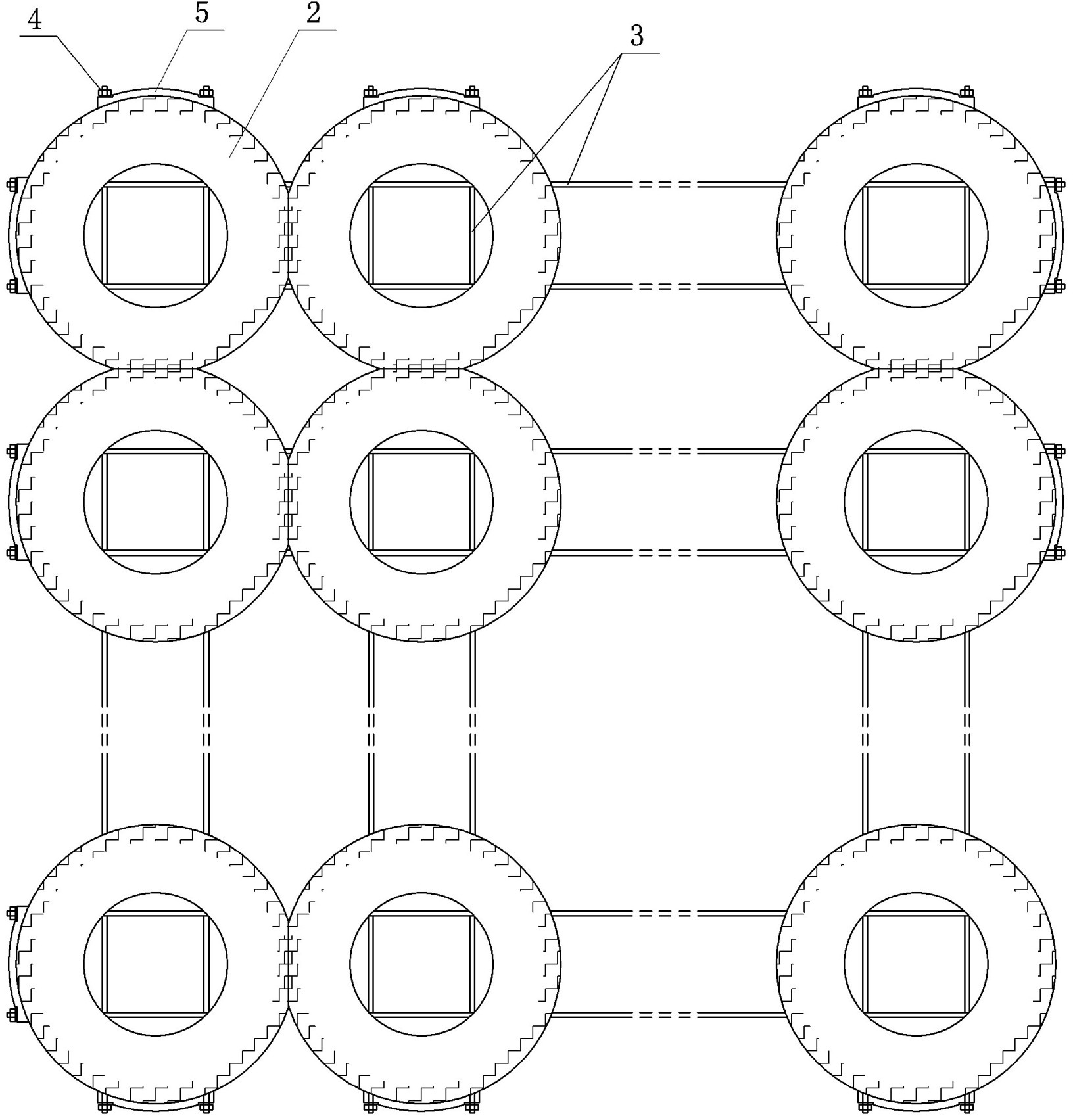

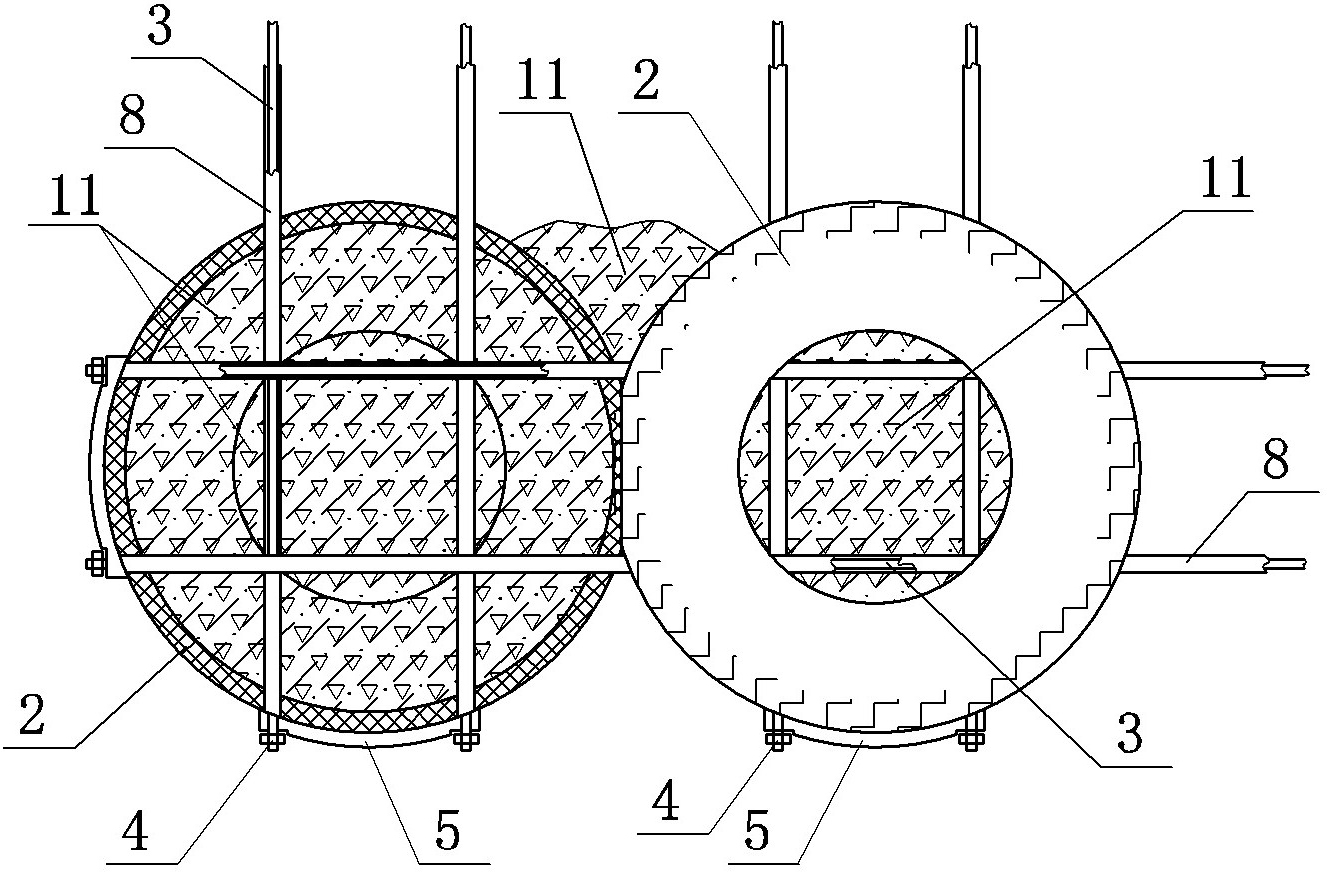

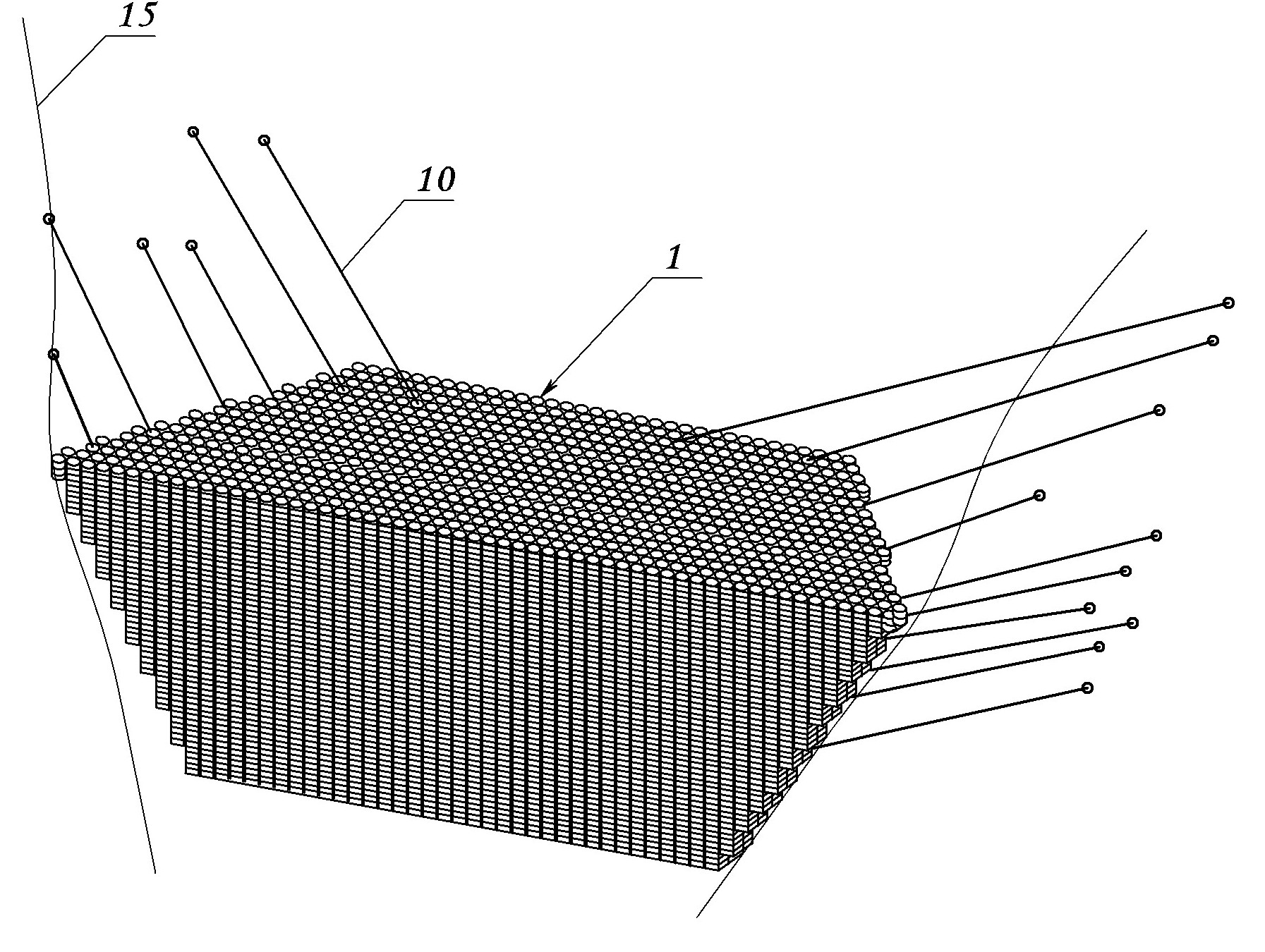

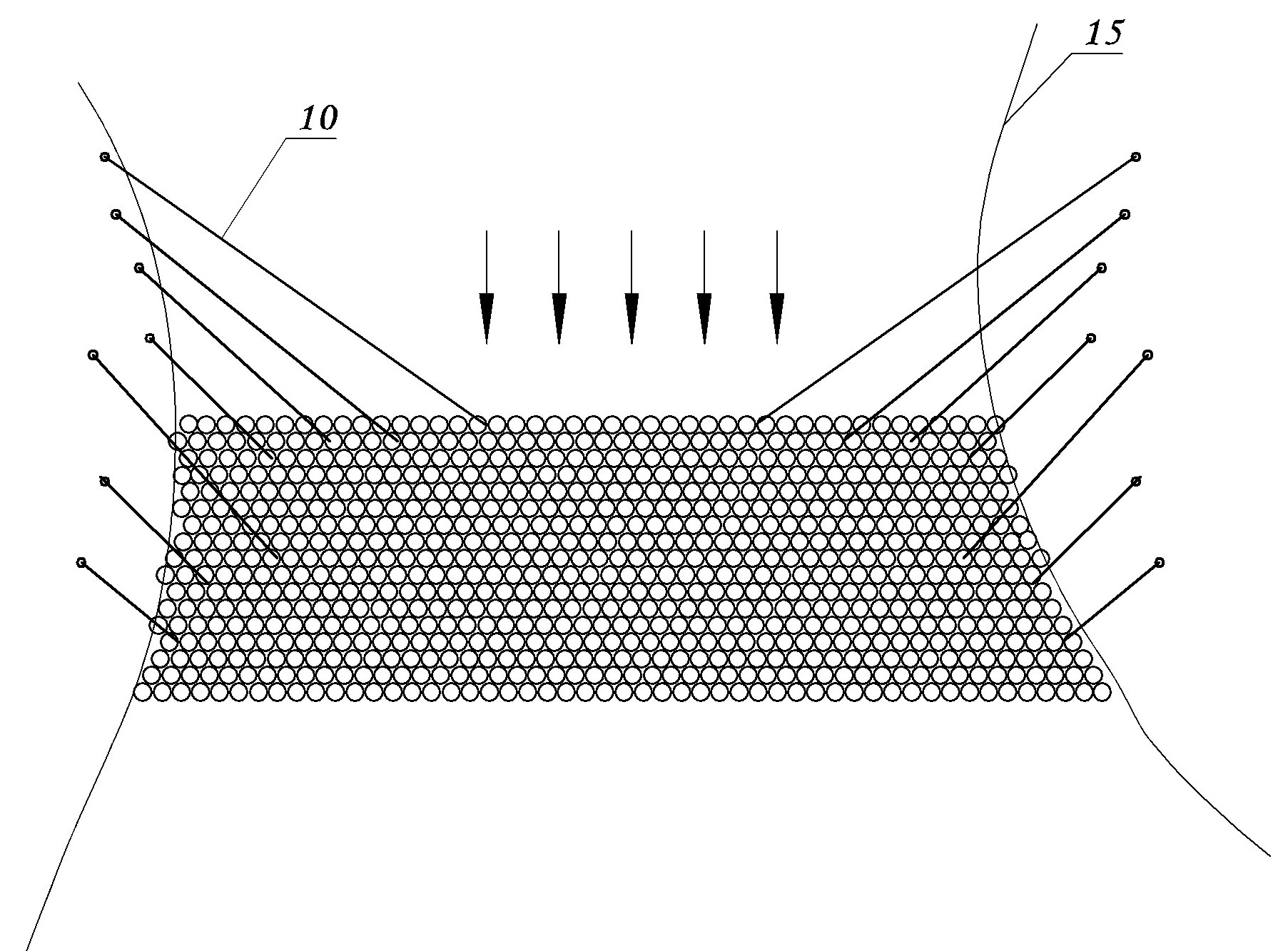

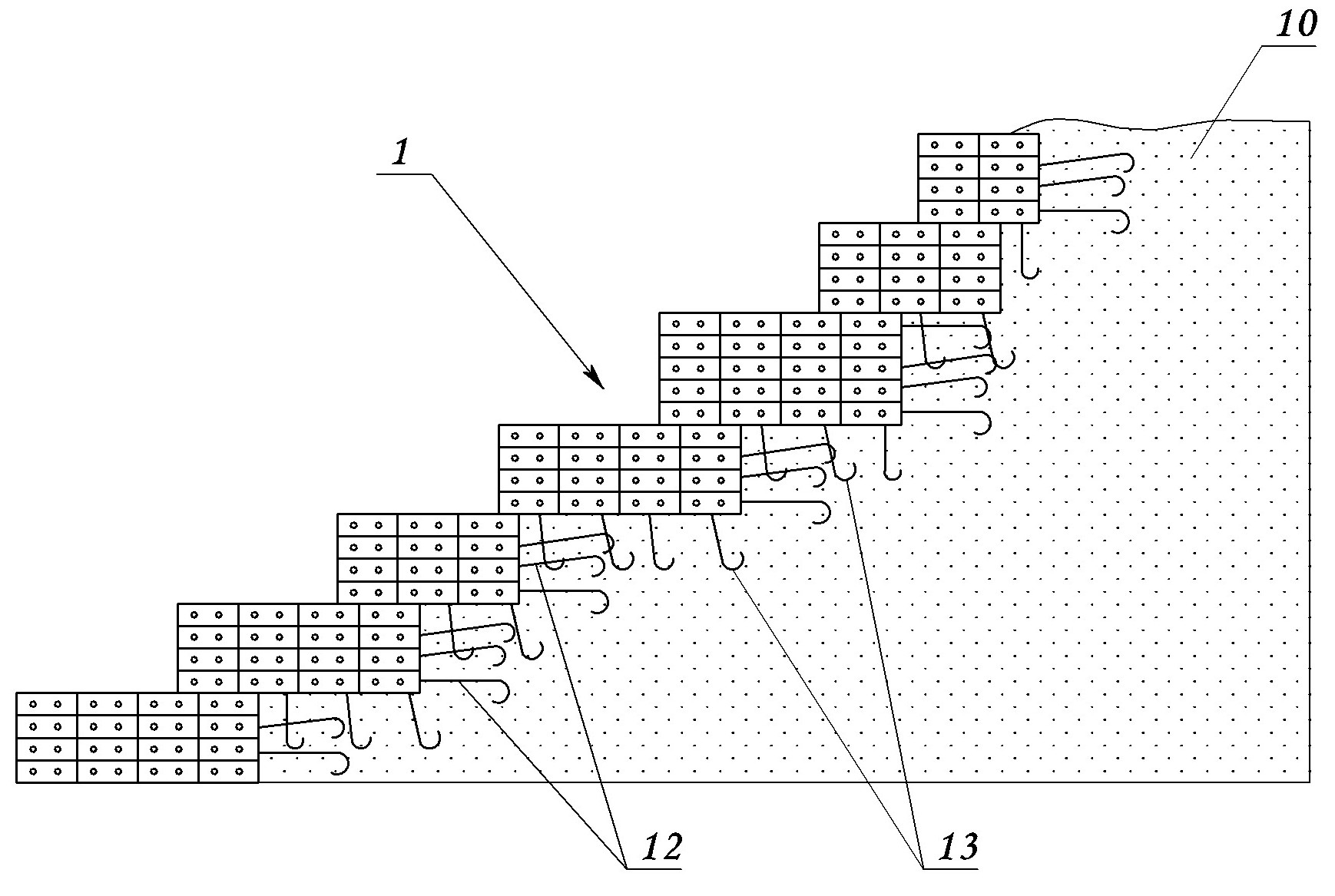

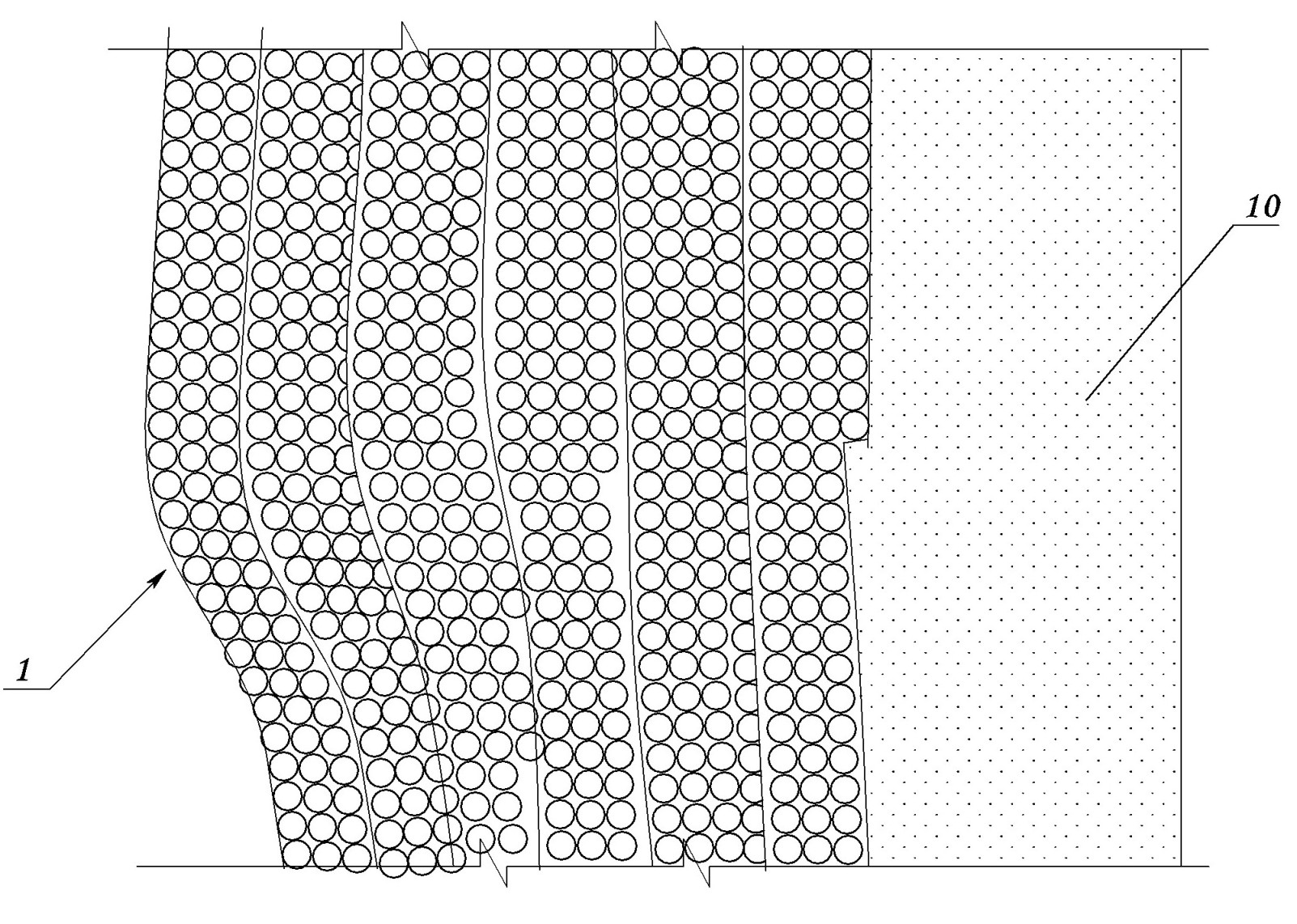

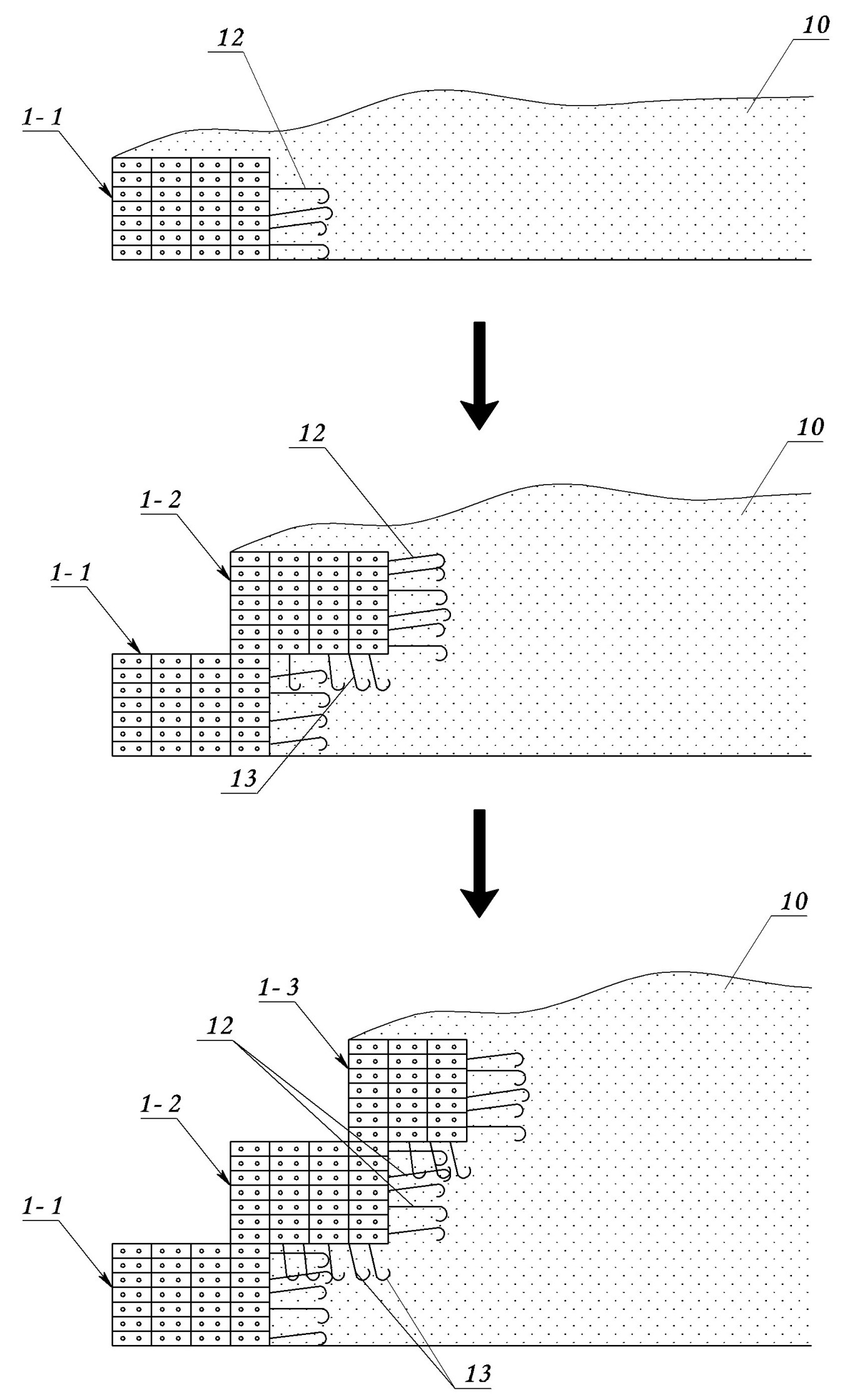

Slope protection or flood control dam using discarded tyres

InactiveCN102425138AAchieve reuseReduce Reuse CostsBreakwatersQuaysGeotechnical engineeringSelf weight

The invention discloses a slope protection or flood control dam using discarded tyres. The slope protection or flood control dam is built by superposing multiple layers of discarded tyre prestressed mesh plates; the discarded tyre prestressed mesh plates are formed by combining multiple discarded tyre prestressed straps; and the discarded tyre prestressed straps are formed by penetrating parallel steel strands through the discarded tyres, prestressing the steel strands, and fixing two ends of the steel strands on outer edges of outmost tyres on two sides. The slope protection or flood control dam using the discarded tyres realizes recycling of wastes at a low cost, and has the advantages of high processing speed, low cost, high transportation speed, rapidness and flexibility in combination and detachment, less resource consumption, capability of regulating the height, the length and other sizes freely, and the like; and the slope protection or flood control dam using the discarded tyres is applicable to on-site quick processing, can meet an emergency requirement, is high in strength, high in impact resistance, high in self-supporting strength, stable and unloose in structure and durable, and is also applicable to manual filling of concrete or stones or filling of gaps between the discarded tyres by using naturally silting sands, stones and the like so as to improve the self weight and the stability and firmness.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Process for recovering waste acid in producing titanium white powder by sulfuric acid method

InactiveCN1171777CImprove filtering effectInhibitionSulfur-trioxide/sulfuric-acidTitanium dioxideAcid concentrationWhite powder

A process for recovering the waste acid in producing titanium oxide powder by the sulfuric acid method features use of gas-liquid separation type non-volatile solution concentrating apparatus. It includes such steps as depositing the waste acid to receiver solid Ti, pre-concentrating at 50-60 deg.C until acid concentration is 40-50%, filtering, and concentrating at 65-75 deg.C until its concentration reaches more than 70%.

Owner:吉林市吉研高新技术开发公司 +1

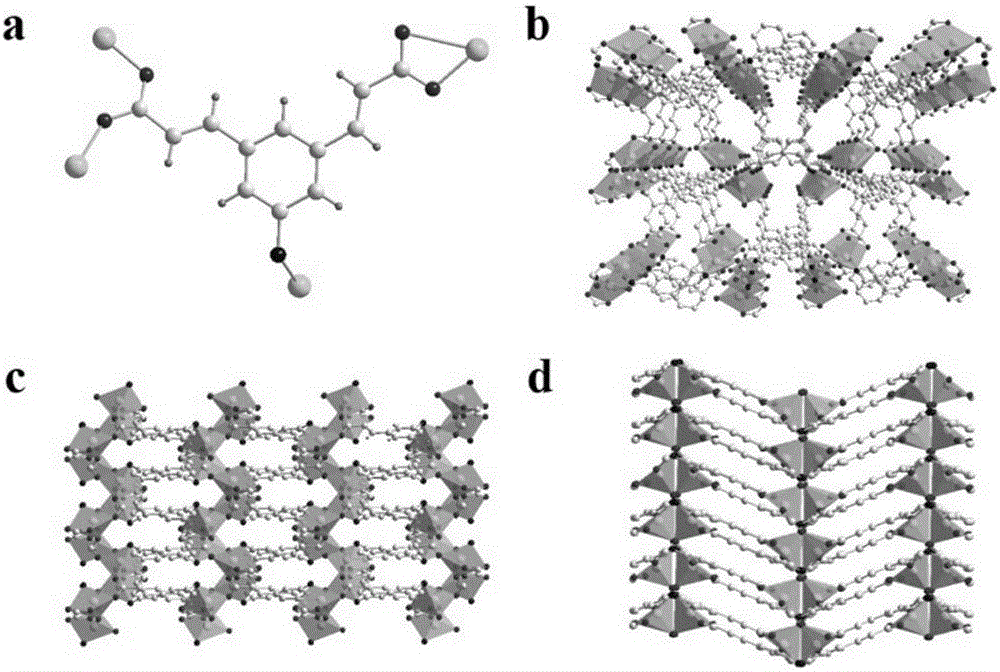

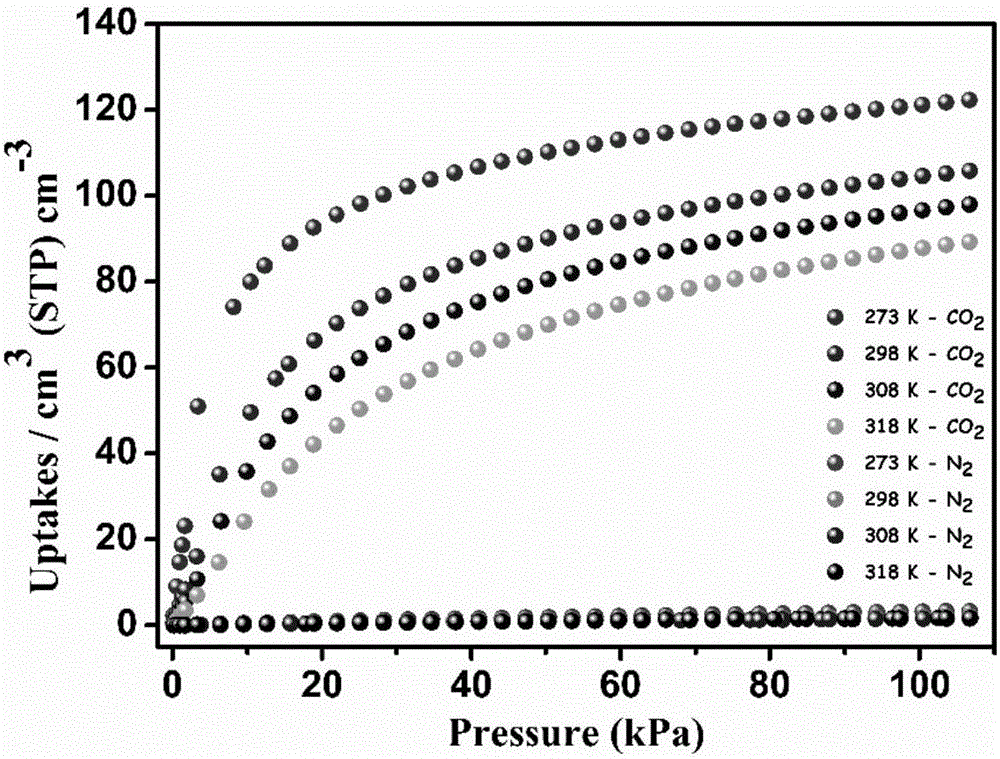

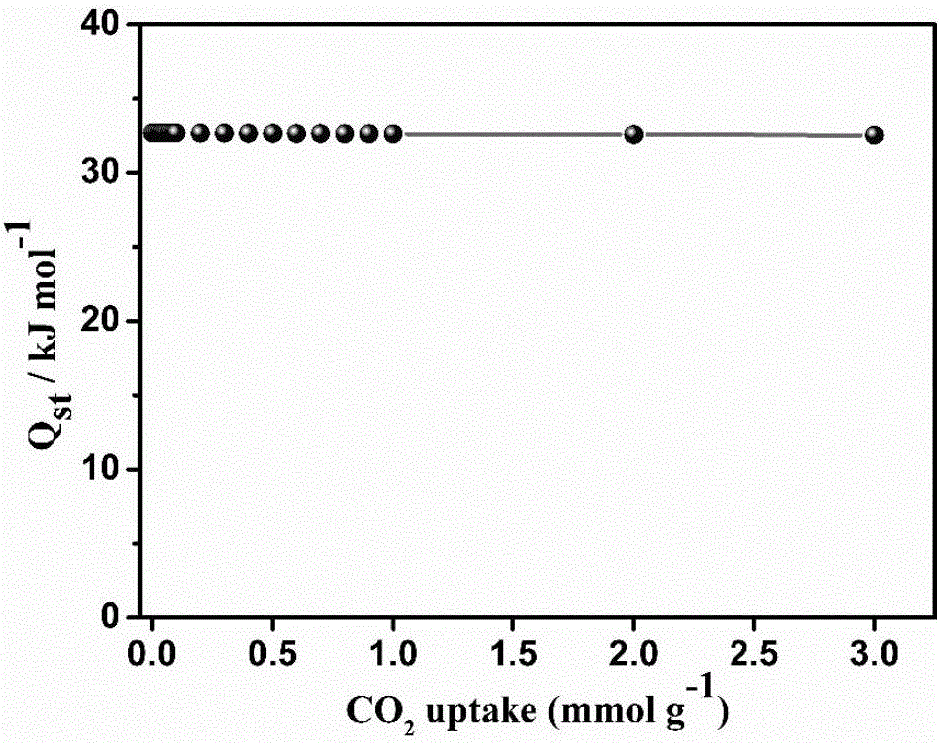

Metal-organic framework material for efficient CO2/N2 selective separation and adsorption and preparation method of metal-organic framework material

The invention discloses a metal-organic framework material for efficient CO2 / N2 selective separation and adsorption and a preparation method of the metal-organic framework material. The preparation method of the metal-organic framework material comprises steps as follows: firstly, organic ligands are obtained through cross coupling reaction, secondly, a homogeneous-phase crystal material is obtained with a solvent thermal method, thirdly, repeated solvent exchange is performed with anhydrous acetone with a lower boiling point, and finally, solvent molecules in holes of the material are removed in a higher vacuum state, so that the activated crystal material is obtained. The material realizes zero adsorption of N2 for the first time, has high CO2 / N2 selective separation and adsorption performance and lower isothermal adsorption enthalpy and is low in reuse cost; besides, the material has excellent chemical stability and heat stability, greatly meets multi-aspect requirements for the CO2 / N2 selective separation and adsorption material in the actual application field, and has great application prospect in the field of CO2 / N2 selective separation and adsorption and in the aspect of relieve of greenhouse effect.

Owner:ZHEJIANG UNIV

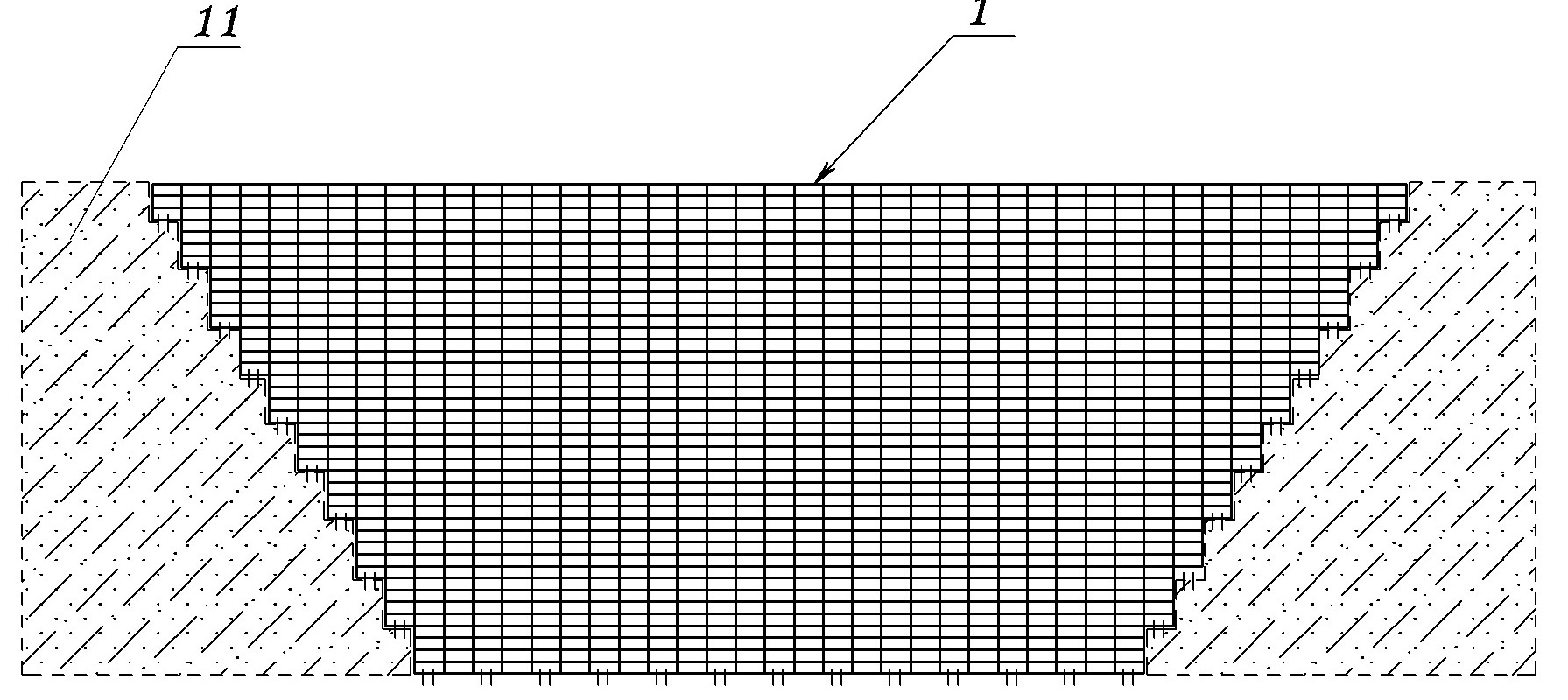

Soil-retaining dam and construction method thereof

InactiveCN102518086AHigh strengthExtended service lifeEmbankmentsWall damsPre stressArchitectural engineering

The invention discloses a soil-retaining dam which is formed by combining waste tyres, and a construction method thereof. A dam body is formed by stacking a plurality of layers of waste tyre prestressed mesh sheets; each of the waste tyre prestressed mesh sheets is formed by combining a plurality of waste tyre prestressed belts; each of the waste tyre prestressed belts is formed when parallel steel stranded wires pass through each waste tyre; two ends of each of the steel stranded wires are fixed on the outer edges of the outmost tyres of two ends respectively after each of the steel stranded wires applies prestress to each waste tyre; nodes are arranged on the prestressed steel stranded wires on the inner side of the dam body; a steel rope is fixedly arranged on each node; and each steel rope is pulled towards the upstream of a channel obliquely along a counter current direction and is fixed at a dam slope of a dam foundation. Through the soil-retaining dam and the construction method thereof, wastes can be recycled in low cost; the soil-retaining dam is suitable to be processed on site quickly so as to meet the requirements in emergencies, is high in strength and impact resistance, has a stable structure, cannot be loose and is durable in use; the dam body is high in self-supporting strength; and the self weight and stability of the soil-retaining dam can be improved by filling concrete, stone materials, sand and stones which are silted up naturally and the like manually in gaps among the waste tyres.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

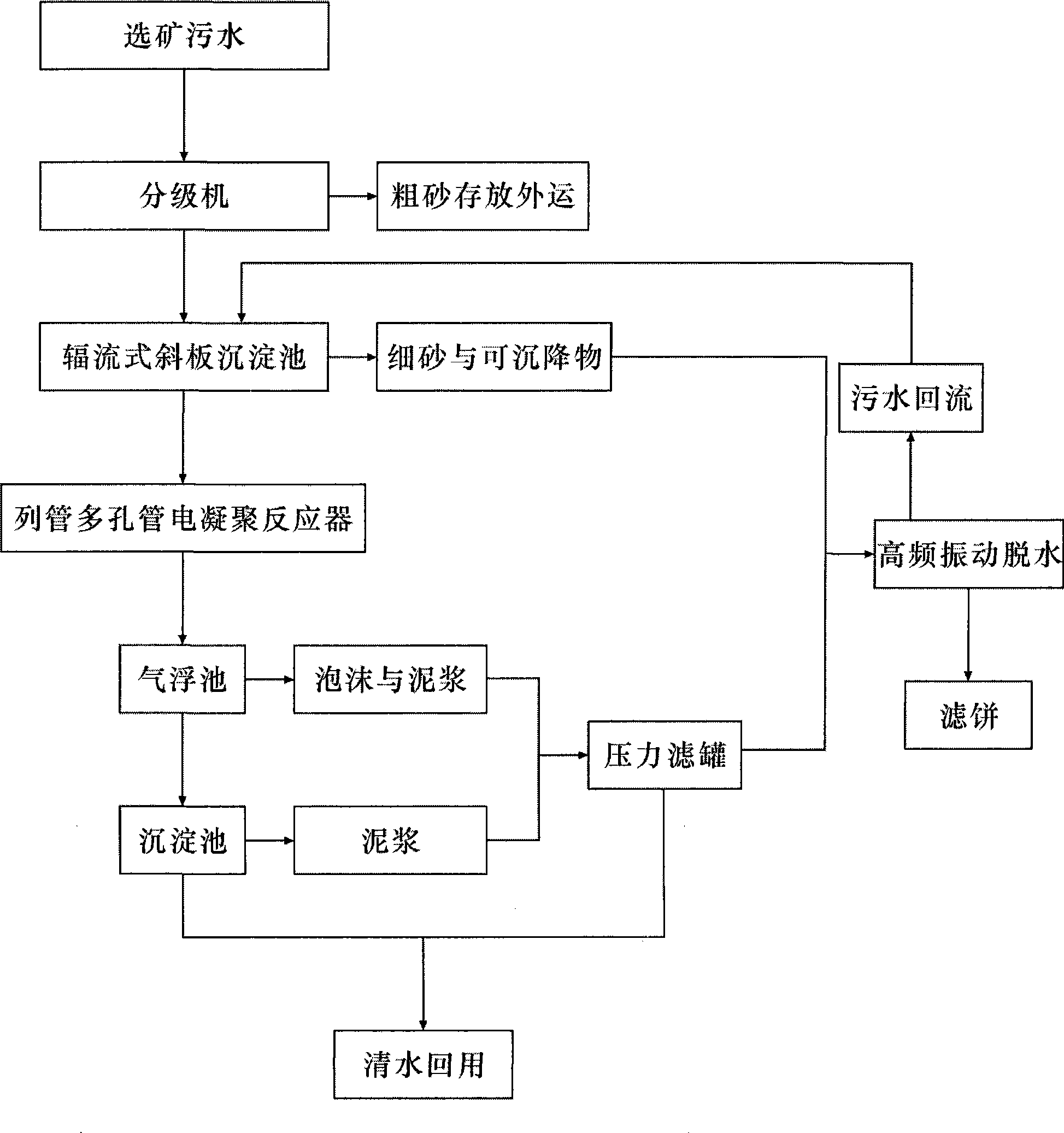

Sewage treatment method for fluorite concentration plant

InactiveCN101468857AStrong colloidal activityNo worries about secondary pollutionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFiltrationPollution

The invention relates to a method for treating wastewater in a fluorite dressing plant. The method comprises the following treating steps: fractionated precipitation, electrocoagulation, air floatation and decontamination, advection-type precipitation, filtration of a treated solution and dehydration treatment of sediment. The method has the advantages of no addition of a chemical agent, low treatment cost, no secondary pollution, no regulation of pH value of wastewater and wide application range.

Owner:陈艳锋

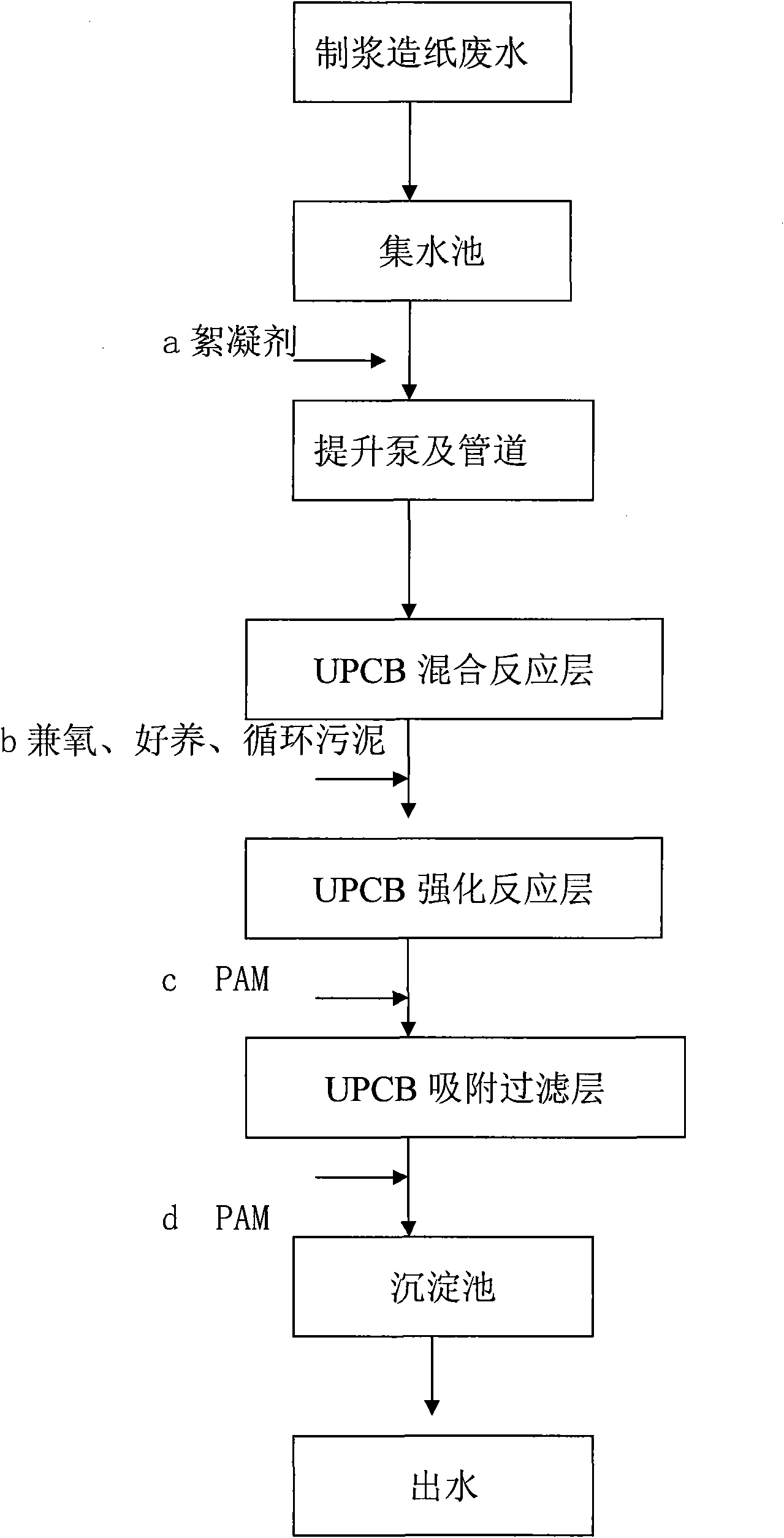

Treatment method of waste papermaking water

ActiveCN101781055ALow densitySlow separationSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentFlocculationFiltration

The invention relates to a treatment method of waste papermaking water, which comprises the steps of filtration, sand setting, flocculation and sedimentation and separation and reuse. The invention is characterized in that before adding flocculating agents into reclaimed water to be treated for flocculation and sedimentation, the flocculating agents which account for 70 to 90 weight percent of the total consumption carry out desalted treatment. When the method of the invention is adopted, the waste papermaking water with high salt content can be treated at the low cost, and in addition, satisfactory results can be obtained.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Method for recycling wasted SCR denitrification catalyst

InactiveCN104624050AReduce Reuse CostsSimple and fast operationDispersed particle separationPolyethylene glycolAmmonium metavanadate

The invention discloses a method for recycling a wasted SCR denitrification catalyst. The method comprises the following steps of effectively cleaning a wasted SCR catalyst by a cleaning solution prepared from a microporous penetrating agent JFC-1, peregal O and acetic acid by adopting a bubble cleaning method; and cutting the wasted SCR catalyst, cleaning, drying, crushing, mixing the crushed wasted SCR catalyst with ammonium molybdate, ammonium metavanadate, oxalic acid, glass fibers, hydroxypropyl methyl cellulose, polyethylene glycol-400 and water, and re-preparing a plate-type denitrification catalyst. The method provided by the invention is simple and convenient to operate, low in cost, and free of secondary pollution to the environment in the recycling process; in addition, the plate type catalyst prepared from the recycled material is high in activity, intensity and abrasion resistance, has the certain sulfur poisoning resistant capability, and recycles the waste SCR denitrification catalyst well.

Owner:北京宏庚环保科技有限公司

Method for building waste tyre sand resisting dam and waste tyre sand resisting dam

InactiveCN102518053AAchieve reuseReduce Reuse CostsDamsProtective constructionEnvironmental engineeringWaste management

The invention discloses a method for building a waste tyre sand resisting dam and the waste tyre sand resisting dam. The waste tyre sand resisting dam is formed by piling up one to n waste tyre sand resisting layers gradually, wherein each sand resisting layer is formed by stacking a plurality of layers of waste tyre prestressed mesh sheets; each of the waste tyre prestressed mesh sheets is formed by combining a plurality of waste tyre prestressed belts; each of the waste tyre prestressed belts is formed when parallel steel stranded wires pass through each waste tyre; and two ends of each of the steel stranded wires are fixed on the outer edges of the outmost tyres of two ends respectively after each of the steel stranded wires applies prestress to each waste tyre. Through the method for building the waste tyre sand resisting dam and the waste tyre sand resisting dam, wastes can be recycled in low cost; the waste tyre sand resisting dam can be processed quickly, is low in cost, can be allocated and transported quickly, can be assembled or disassembled quickly and flexibly, is low in resource consumption and is high in strength and impact resistance; and a transverse anchor rod is arranged at the position where the inner side edge of each waste tyre sand resisting layer contacts sand to ensure that the waste tyre sand resisting dam is high in self-supporting strength, has a stable structure, cannot be loose and is durable in use.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

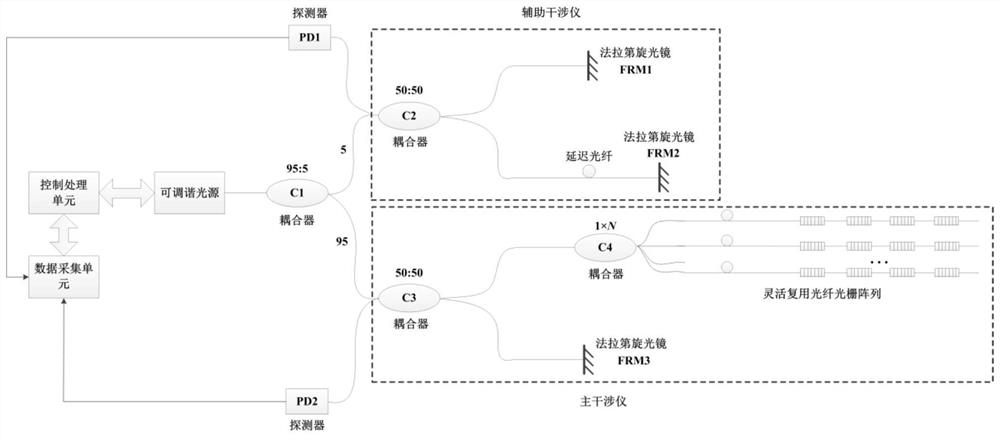

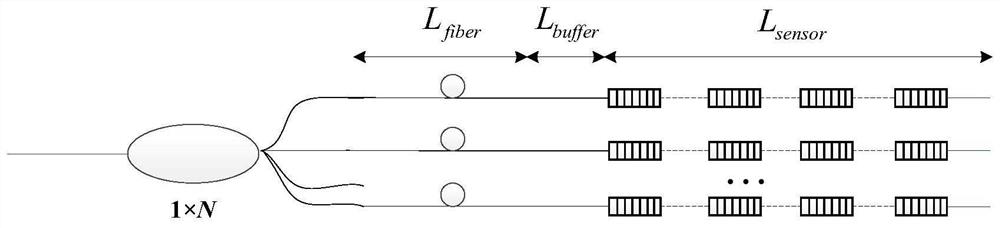

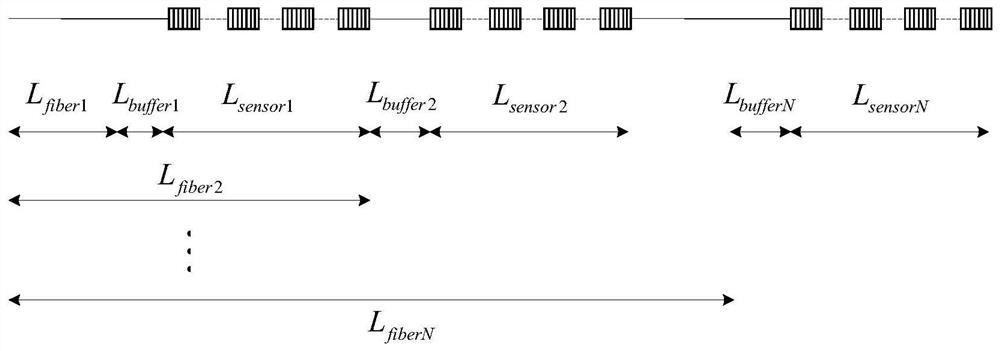

Large-scale fiber bragg grating sensor flexible multiplexing device based on OFDR

PendingCN112129332ARealize flexible reuseReduce Reuse CostsConverting sensor output opticallyMultiplexingGrating

The invention discloses a large-scale fiber grating sensor flexible multiplexing device based on OFDR. The device comprises a tunable light source, a main interferometer, an auxiliary interferometer,photoelectric detectors PD1 and PD2, a data acquisition unit and a control processing unit, wherein the tunable light source provides periodic scanning light with linearly changing wavelengths for themain interferometer and the auxiliary interferometer, the main interferometer comprises a reference arm and a measuring arm, wherein the reference arm is composed of a single-mode optical fiber and aFaraday rotator mirror connected to the tail end of the single-mode optical fiber, the measuring arm is composed of a plurality of identical weak reflection fiber grating sensors, the auxiliary interferometer comprises two paths of single-mode optical fibers with different lengths and Faraday rotator mirrors connected with the tail ends of the single-mode optical fibers, the data acquisition unittakes an auxiliary interferometer beat frequency signal acquired by the photoelectric detector PD1 as an external sampling clock and performs equal optical frequency interval sampling on a main interferometer beat frequency signal acquired by the photoelectric detector PD2, and the sweep frequency nonlinearity of the tunable light source is compensated. According to the scheme, on the premise that devices such as an optical divider and a photoelectric detector are not additionally arranged, flexible multiplexing of the single-channel multi-channel fiber grating sensor is achieved, and the device can be widely applied to multiple fields.

Owner:SHANDONG INST OF AEROSPACE ELECTRONICS TECH

Porous catalytic material and preparation method

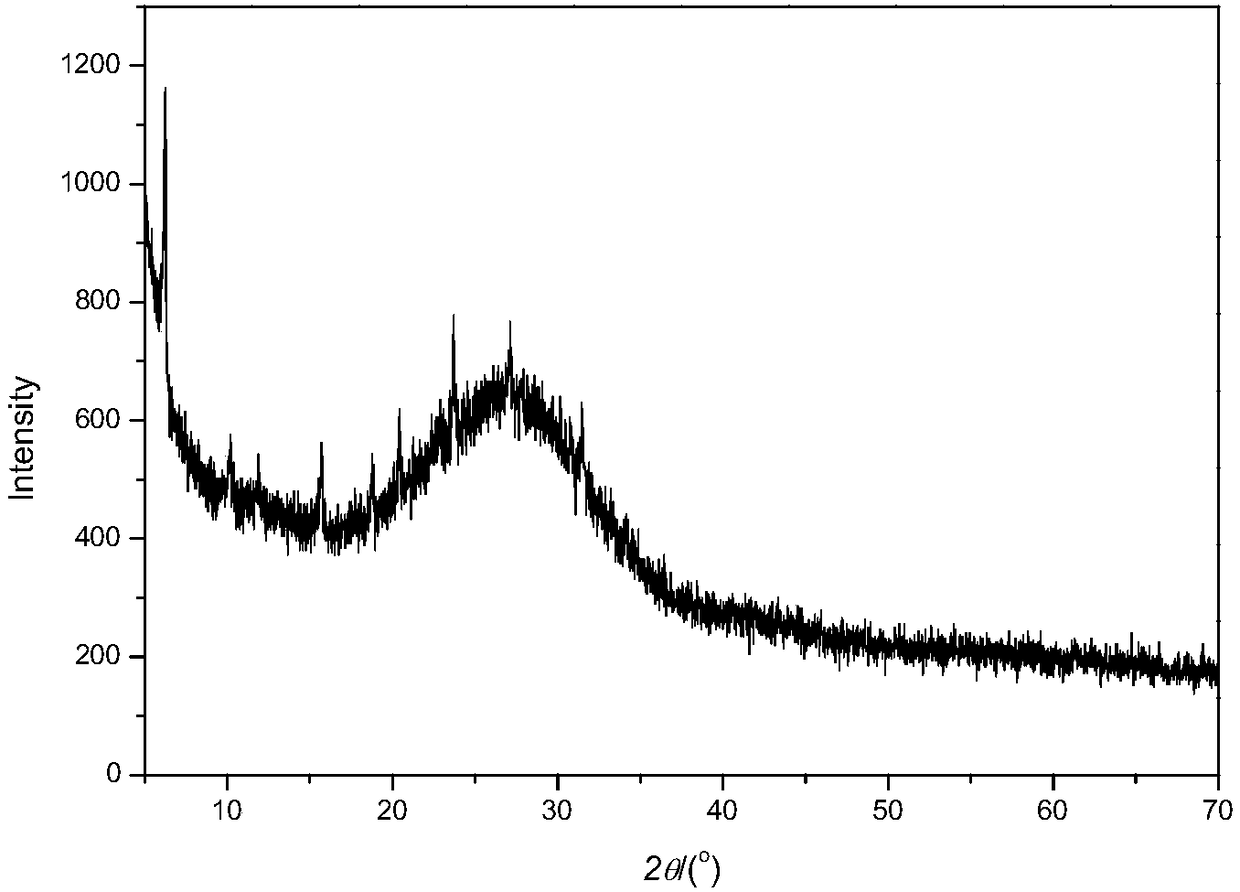

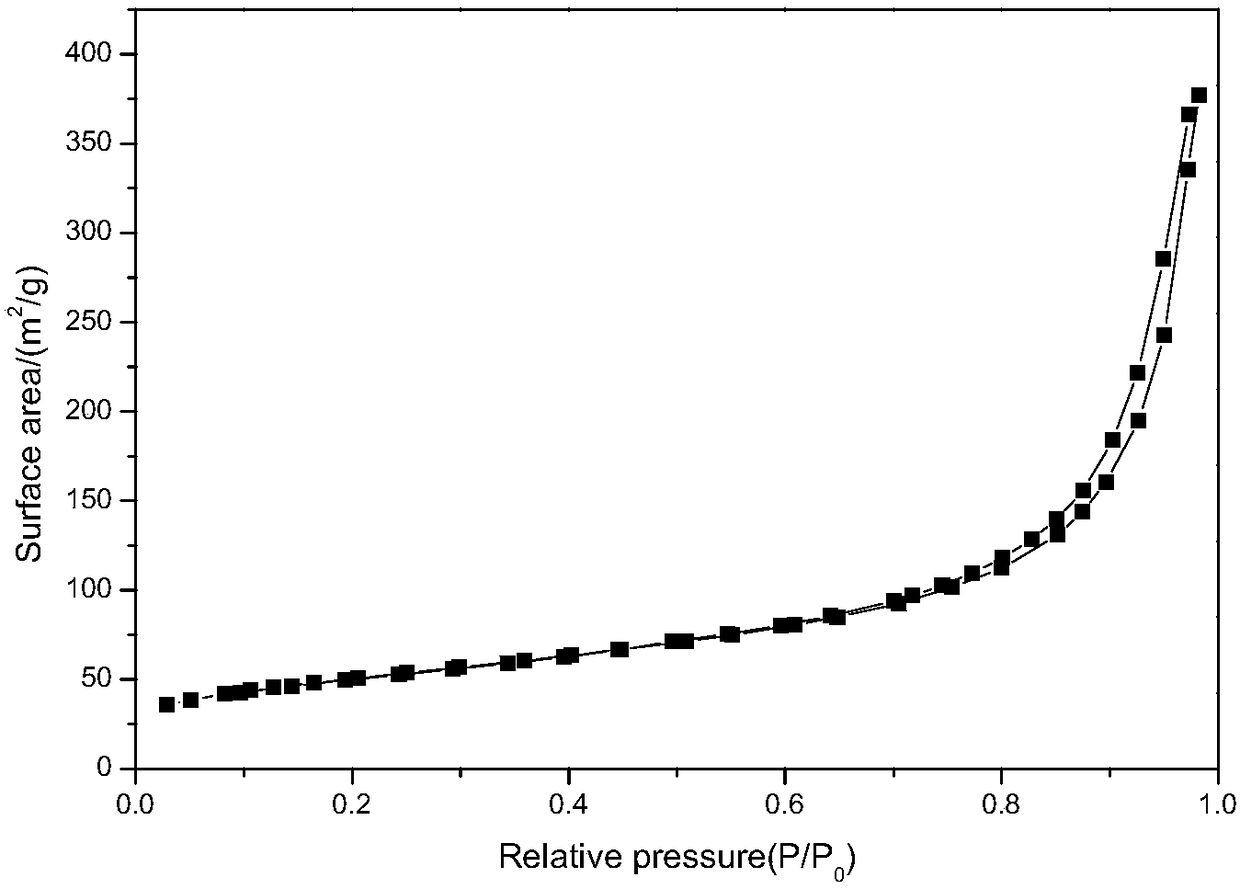

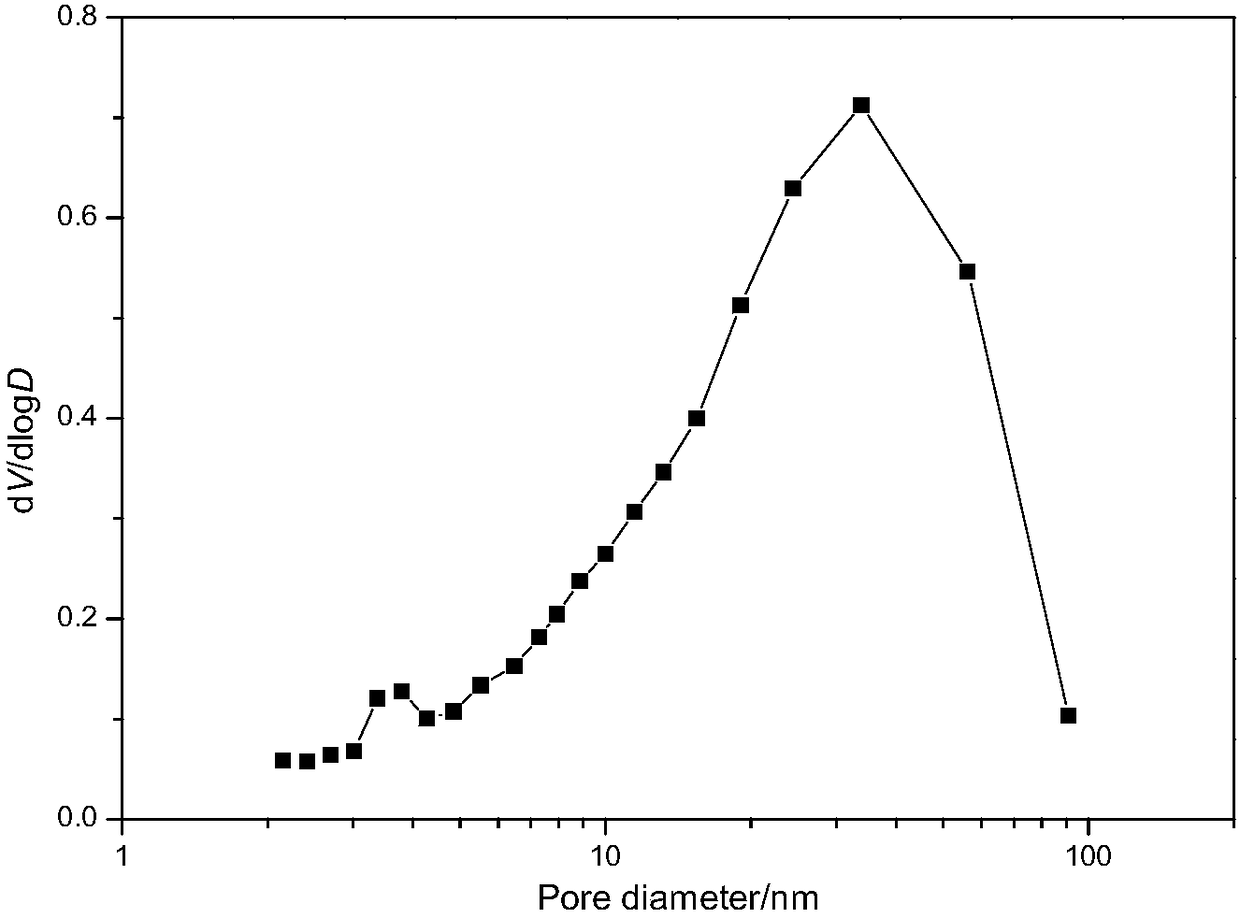

ActiveCN108927123AEnsure accessibilityFacilitate pre-crackingCatalytic crackingPhysical/chemical process catalystsChemical compositionPyridine

Provided is a porous catalytic material. The porous catalytic material has the characteristics that in the XRD spectrum of the catalytic material, a dispersed diffraction peak is shown at a 2theta angle of 25-27 degree, and meanwhile the catalytic material has an FAU crystal phase structure; the chemical composition of the porous catalytic material contains 50-80% of silicon and 20-50% of aluminumby weight of oxides, the total specific surface area is not more than 250 m<2> / g, the ratio of the micropore specific surface area to the total specific surface area is not more than 28%, and the ratio, measured through pyridine-IR at 200 DEG C, of the number of B acid centers to the number of L acid centers is not less than 0.30; and when the surface Al / Si atomic ratio measured by using an XPS method is a, and the bulk-phase Al / Si atomic ratio measured by using an XRF method is b, a / b = 1.1-1.6.

Owner:CHINA PETROLEUM & CHEM CORP +1

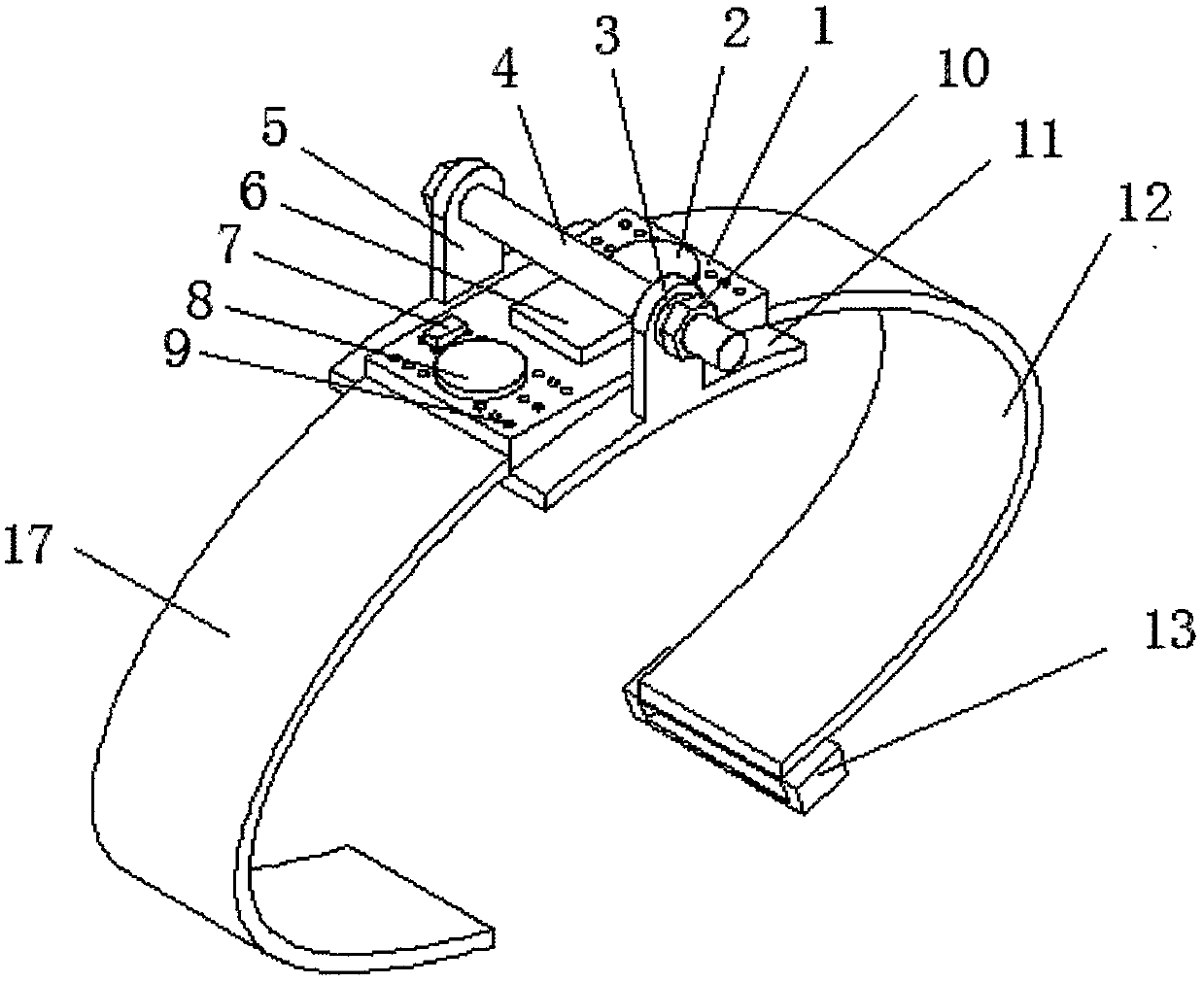

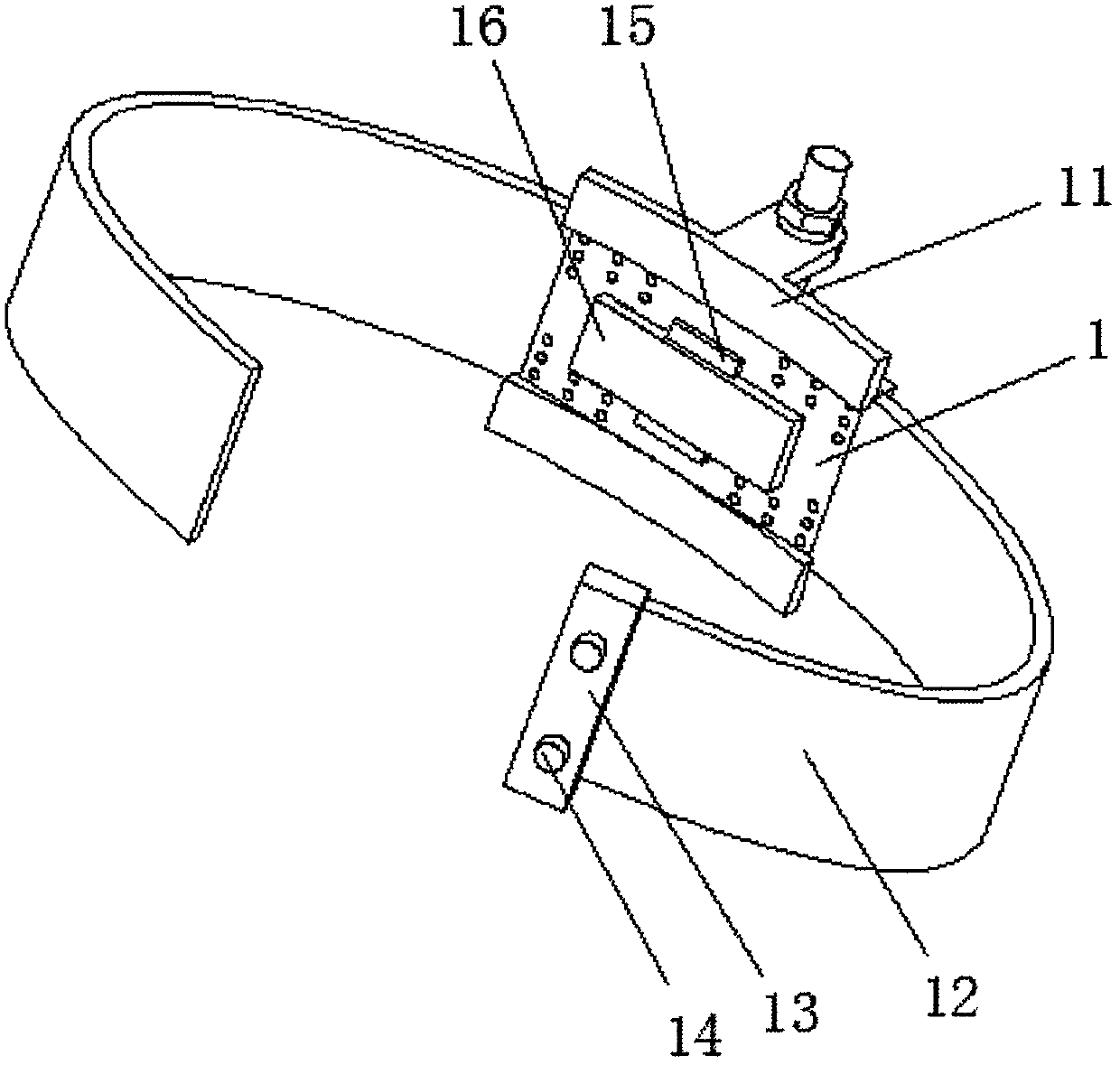

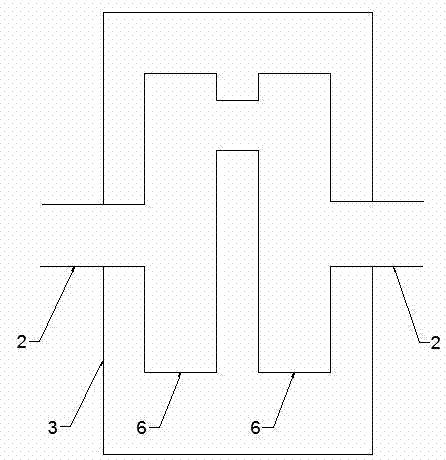

A hemostatic device for vascular surgery arteriovenous surgery

The invention discloses a novel vascular surgery department artery-vein surgical hemostasis device which comprises a first pressing plate. The left end of the first pressing plate is fixedly connected with one end of a second elastic cord, the right end of the first pressing plate is fixedly connected with one end of a first elastic cord, a second pressure gauge, a battery and a first pressure gauge are sequentially arranged on the upper surface of the first pressing plate from left to right, a switch is arranged on one side of the second pressure gauge, second pressing plates are arranged on the front and back sides of the lower surface of the first pressing plate, and the second pressing plates are in sliding connection with the first pressing plate; according to the novel vascular surgery department artery-vein surgical hemostasis device, hemostasis of a wound by compression is achieved through the first pressing plate and a hemostatic medicine bag, the pressure for compressing the wound is convenient to control, adjustment is convenient, artery-vein vessels on the two sides of the wound are made closer through the second pressing plates, wound healing is convenient, rapid hemostasis can be achieved, and the device is simple in structure and convenient to use, capable of being recycled after being disinfected by replacing the hemostatic medicine bag and low in cost.

Owner:胡潍青

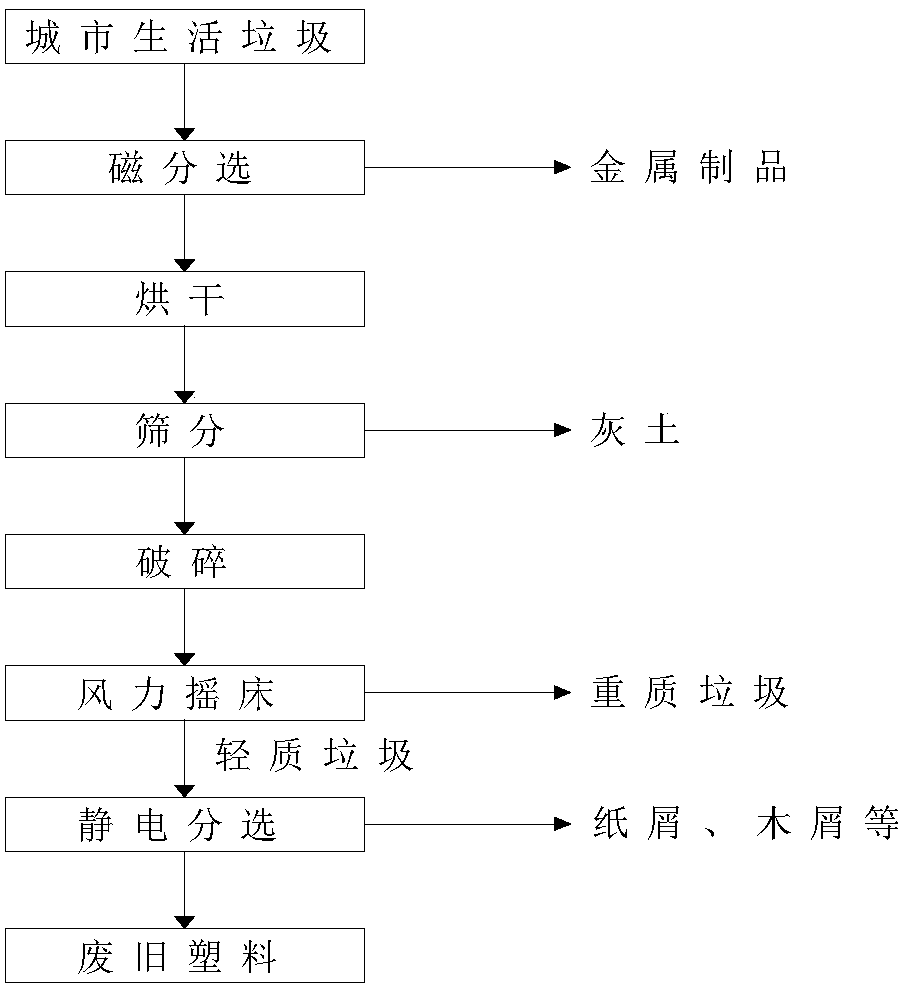

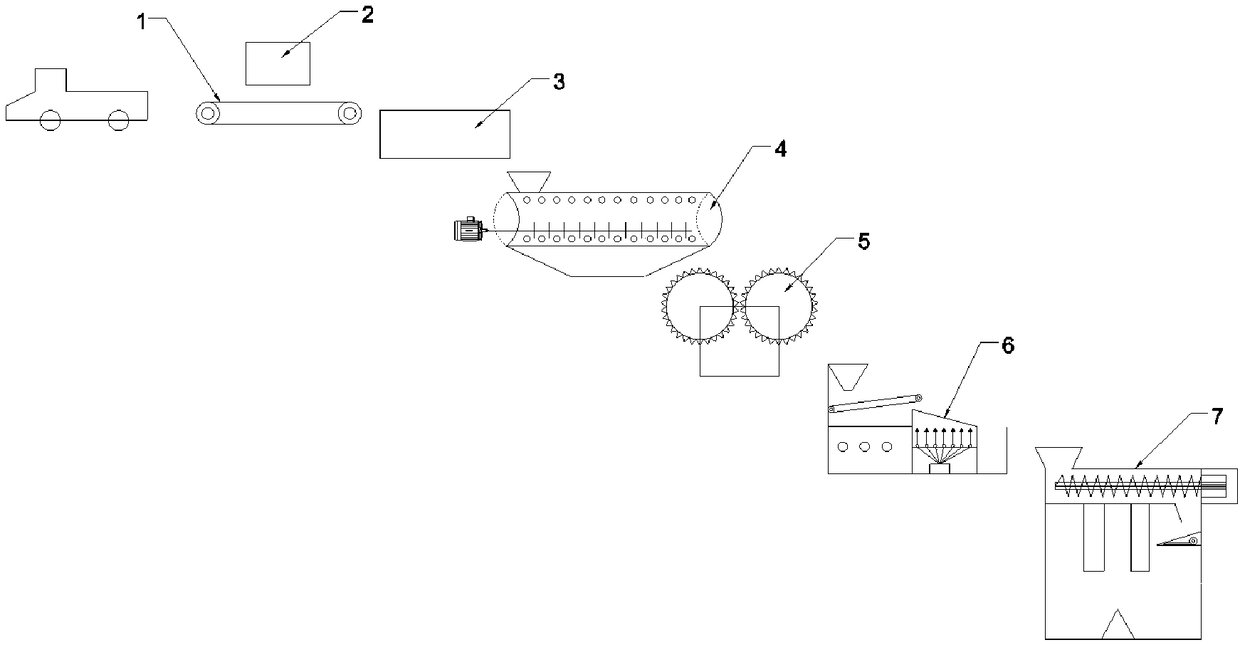

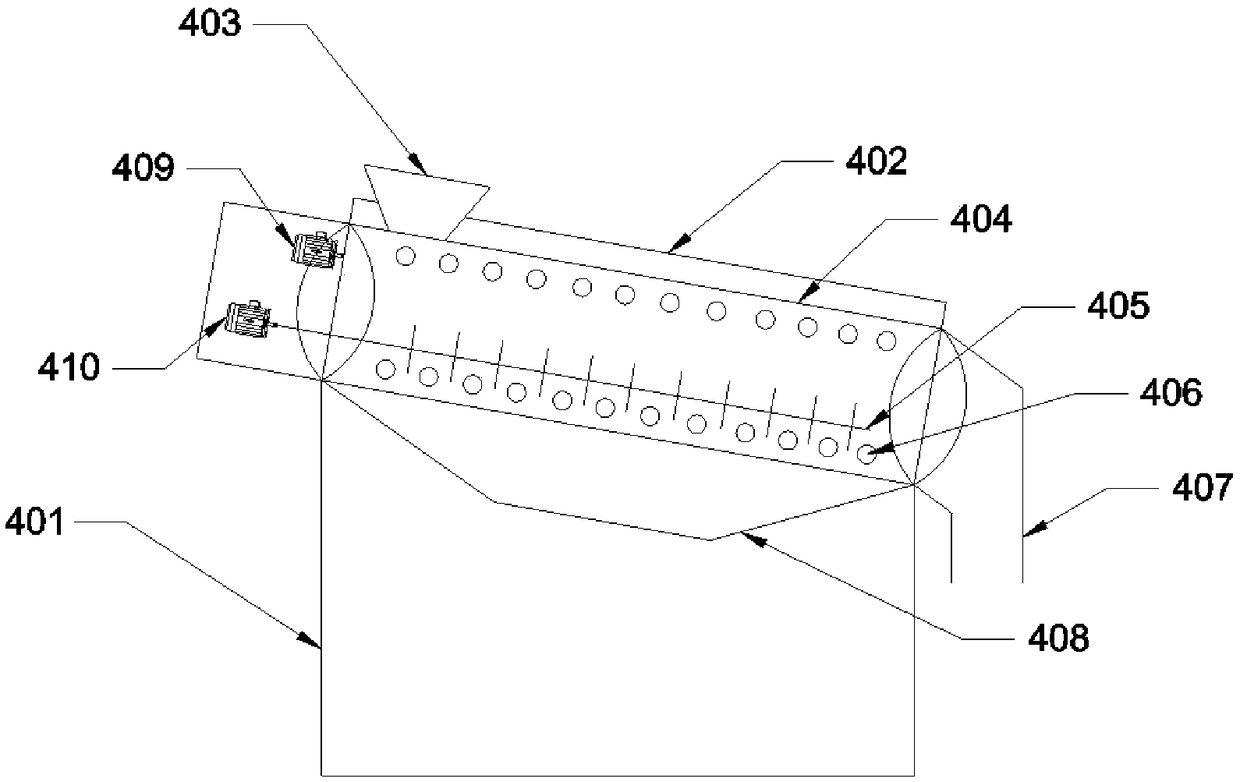

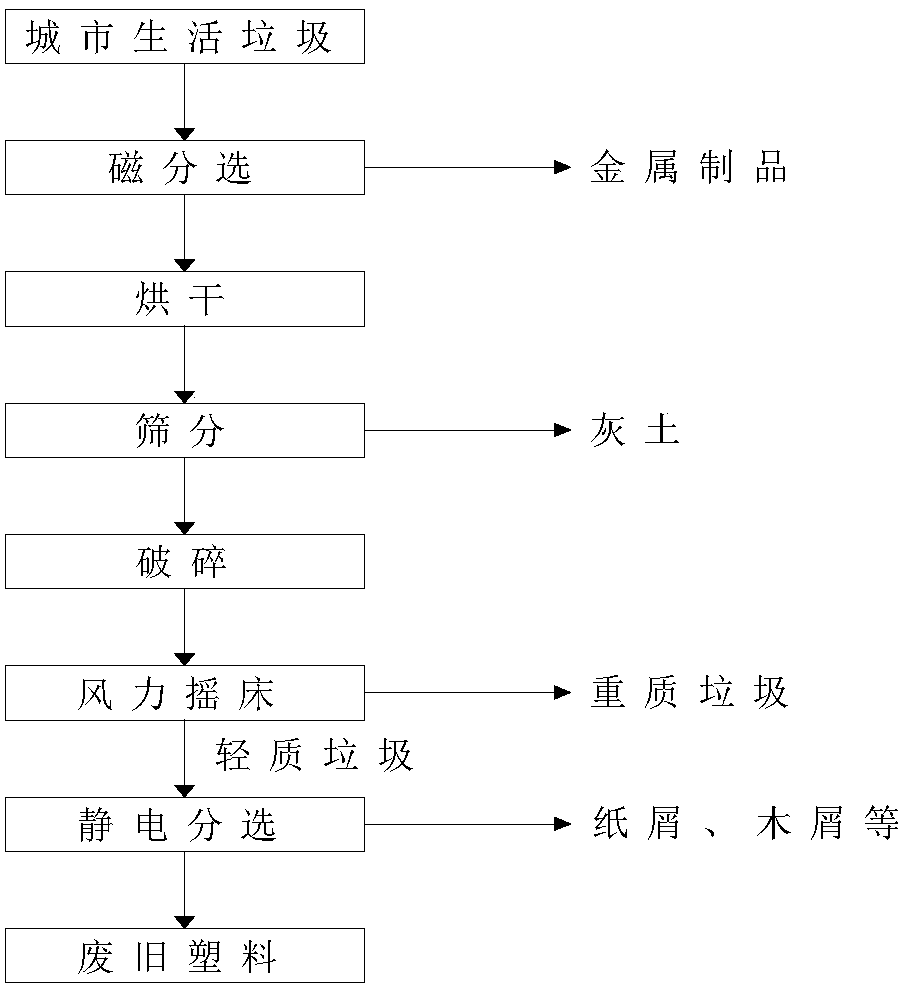

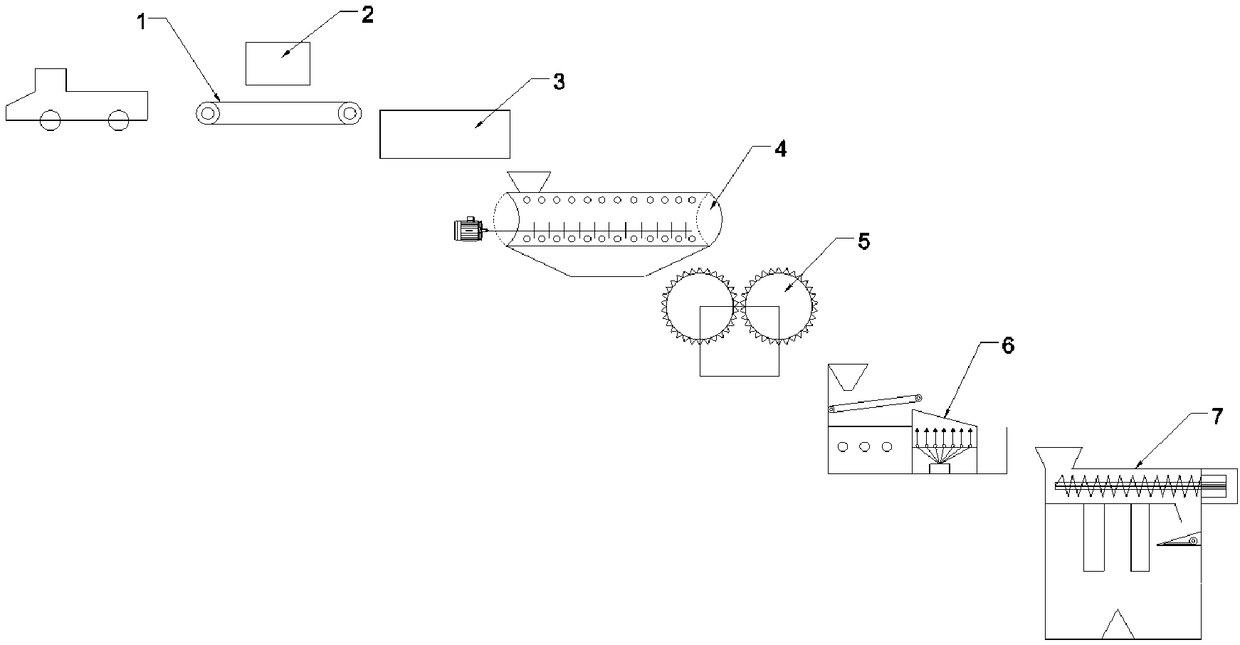

Method and device for sieving plastic from urban household wastes

ActiveCN108312386AHigh purityAvoid flyingPlastic recyclingMechanical material recoveryEngineeringMechanical engineering

The invention discloses a method and a device for sieving plastic from urban household wastes. The method comprises the steps of conveying the household wastes, magnetic sorting, drying, sieving, crushing, sorting through a pneumatic shaking table, electrostatically sorting, and obtaining waste and old plastic. The device adopted in the method comprises a magnetic sorting device, a drying device,a sieving device, a crushing device, a pneumatic shaking bed sorting device and an electrostatic sorting device which are sequentially connected. According to the method, the steps are performed in amatching manner, thus more than 95% plastic can be sorted from the household wastes, and moreover, the sorted plastic is high in purity.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Removal method for dissolved oxygen in recycled water

InactiveCN109110852AEfficient removalEvenly dispersedWater contaminantsWater/sewage treatment by degassingActivated carbonFiber

The invention discloses a removal method for dissolved oxygen in recycled water. The removal method comprises the following steps: enabling the recycled water with dissolved carbohydrazide to pass through a reactor filled with a combined modified activated carbon fiber catalyst; catalyzing carbohydrazide reduction at the low temperature of 40 to 50 DEG C to remove the dissolved oxygen in the recycled water, wherein the combined modified activated carbon fiber catalyst is a catalyst obtained by carrying out high-pressure hydrothermal modification treatment on activated carbon fibers, immersingand loading an active metal salt precursor and roasting. According to the removal method disclosed by the invention, the reaction temperature of the dissolved oxygen in the carbohydrazide and the recycled water is effectively reduced, and the removal effect of the dissolved oxygen in the recycled water is improved; the removal method is especially suitable for removing the dissolved oxygen in output water of three-grade treatment of a sewage treatment plant.

Owner:TAIYUAN UNIV OF TECH

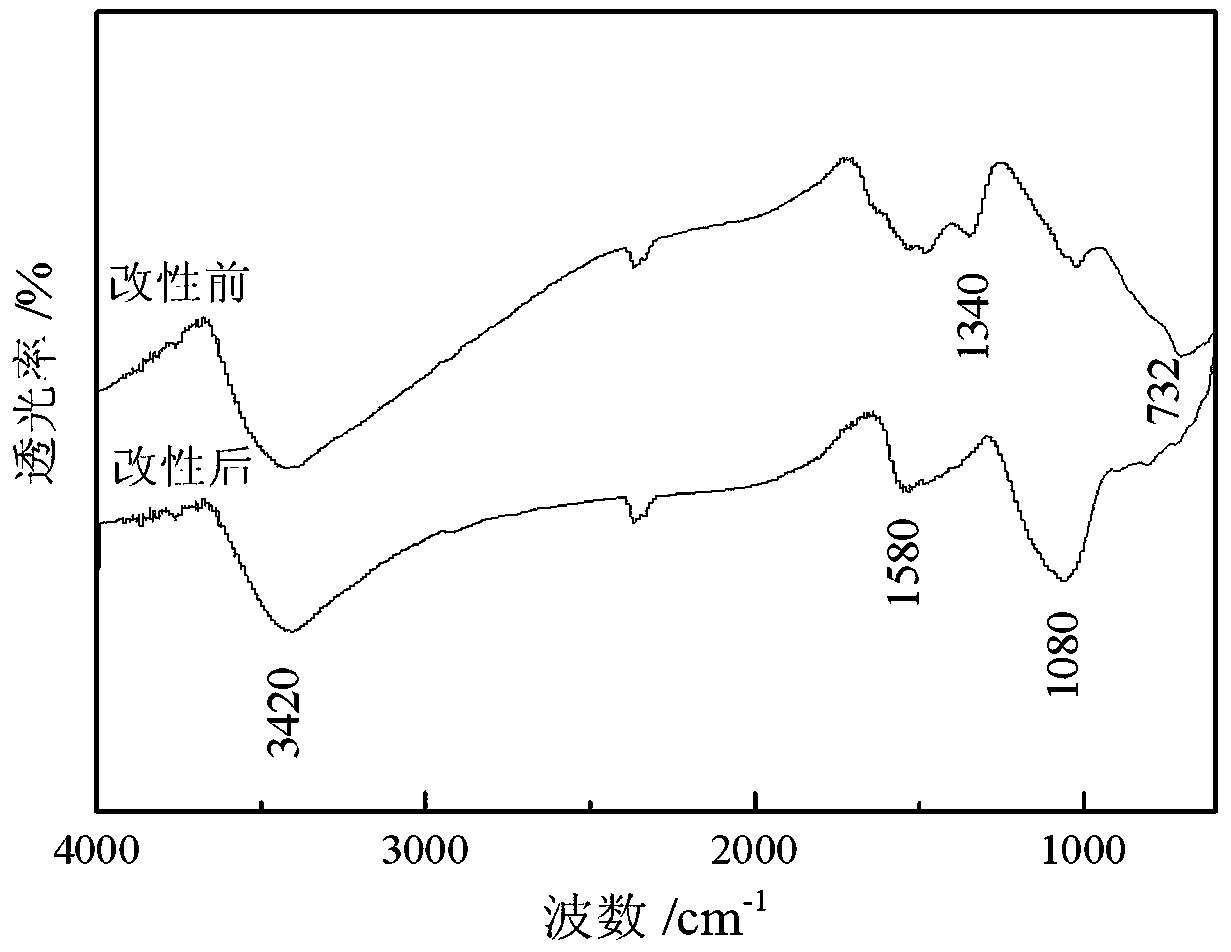

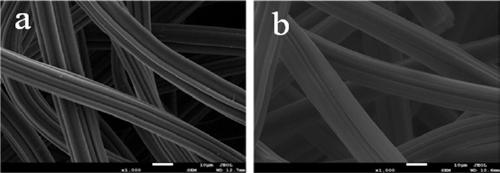

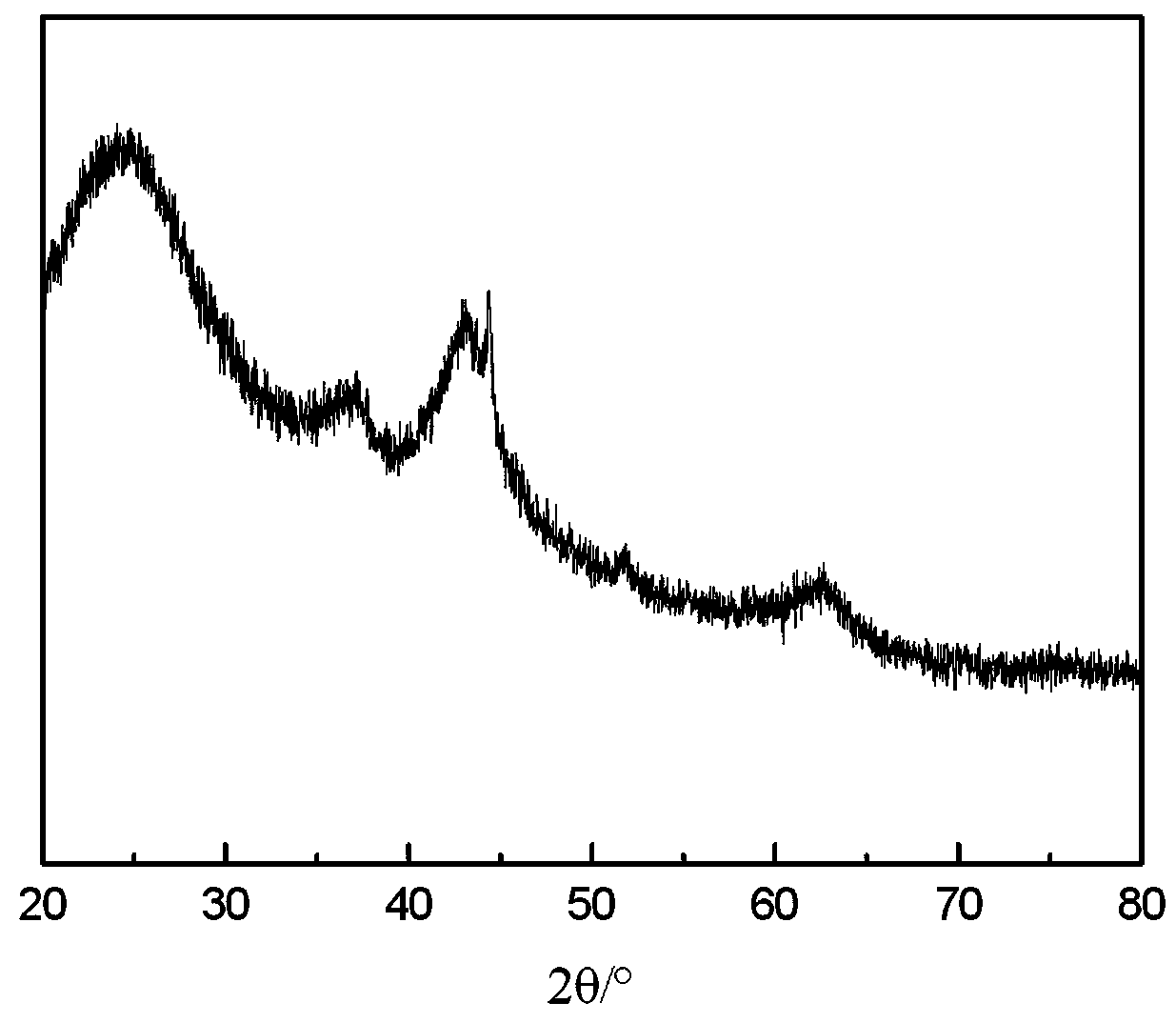

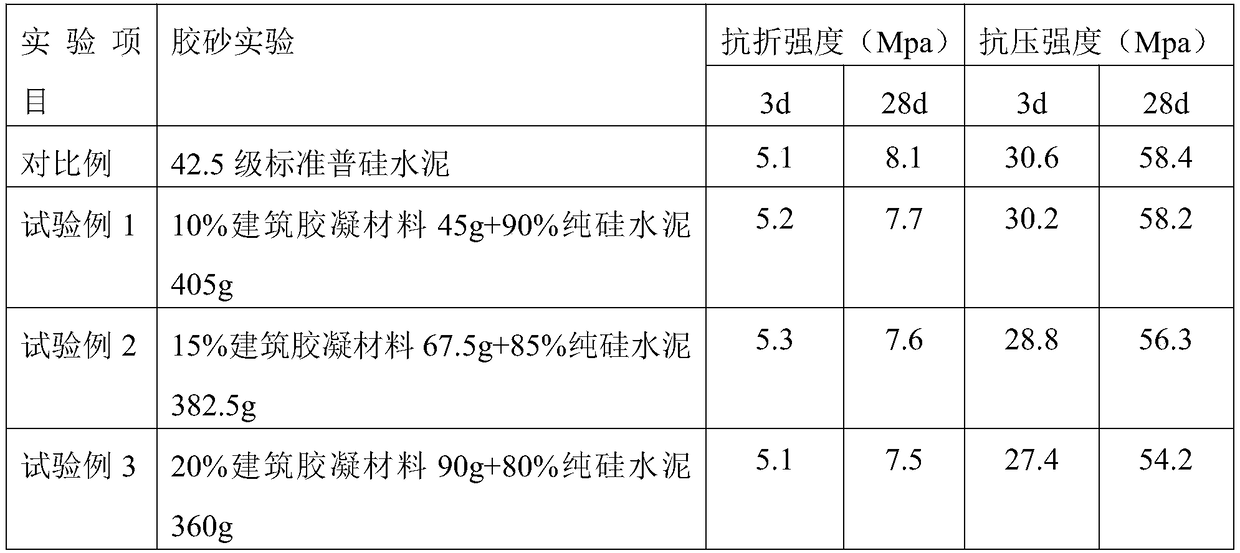

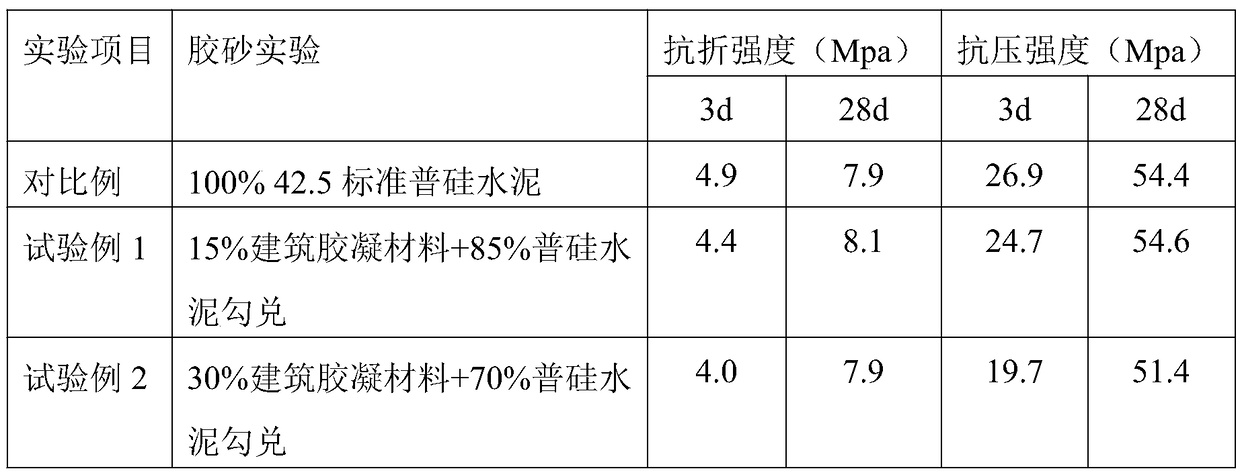

Constructional binding material and construction material

PendingCN109180030ASolving RecyclingHigh content of active ingredientsCement productionSlagBULK ACTIVE INGREDIENT

The invention provides a constructional binding material made by utilizing refined steel slag and industrial residues and a construction material made by utilizing the constructional binding material.The constructional binding material is made by mixing and grinding stainless steel refined steel slag and industrial residues, wherein the stainless steel refined steel slag is AOD (Argon Oxygen Decarburization) furnace steel slag while smelting stainless steel; and the industrial residues refer to steel plant residues and / or steel slag tailings. The construction material is made by mixing the constructional binding material and cement or concrete. According to the constructional binding material and the construction material provided by the invention, the problem that the stainless steel refined steel slag cannot be recycled can be effectively solved. Moreover, the constructional binding material is high in content of active ingredients, and during practical application, the use intensity of the construction material can be effectively improved, and the timeliness of the use intensity is prolonged.

Owner:广西北港新材料有限公司

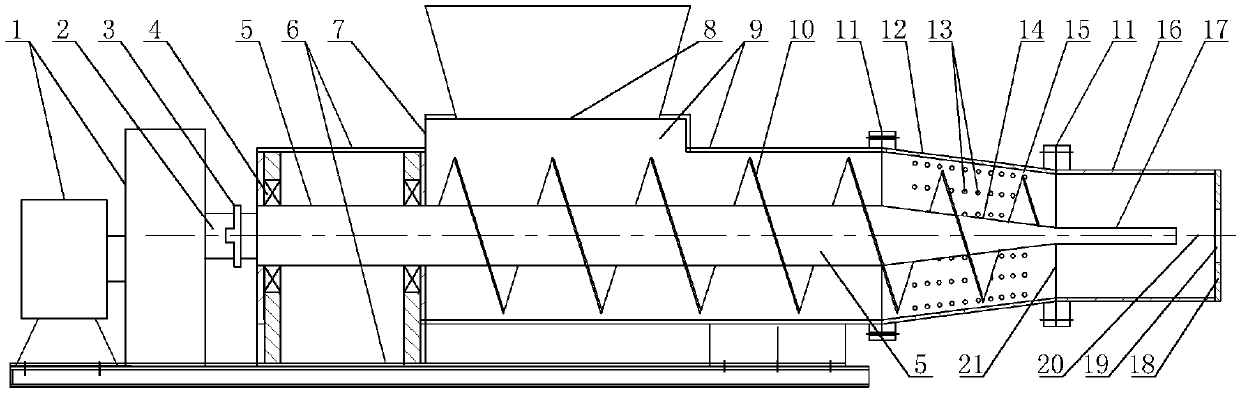

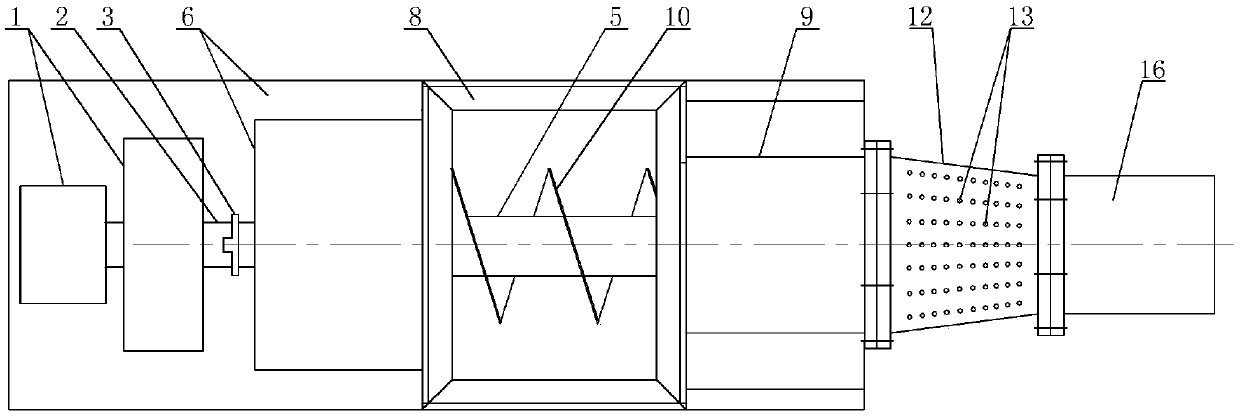

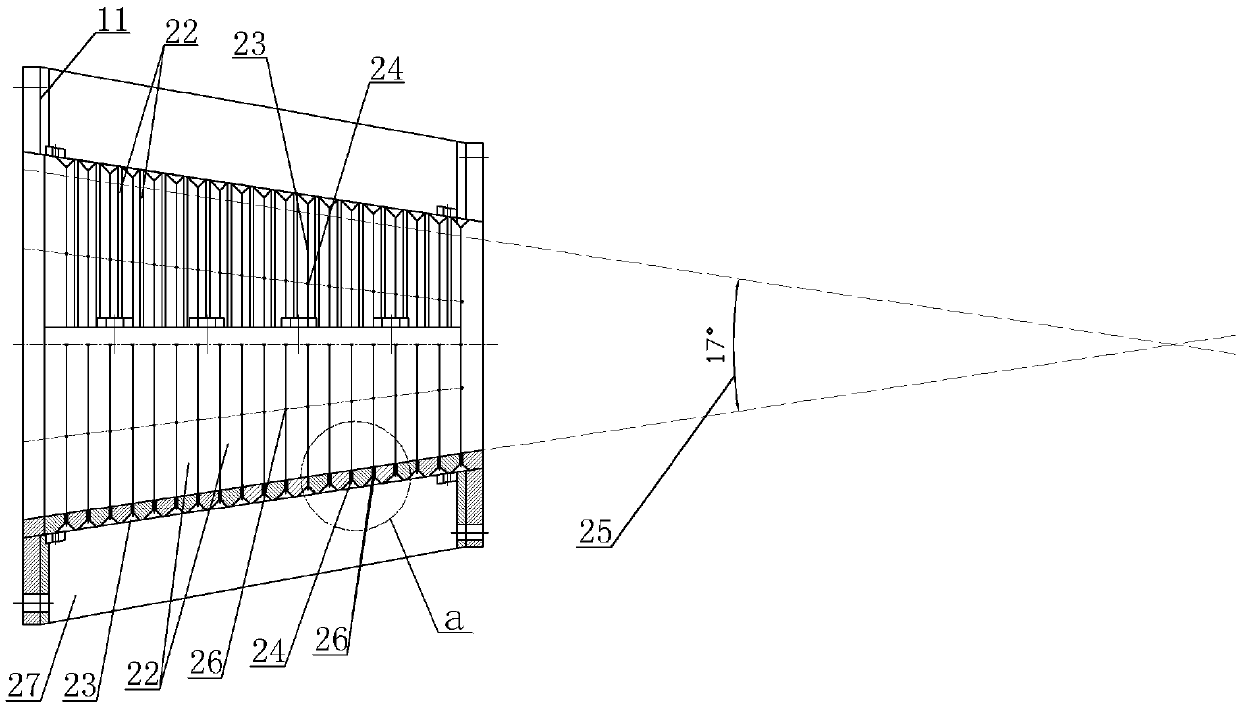

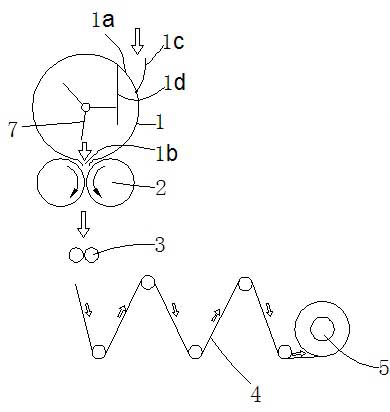

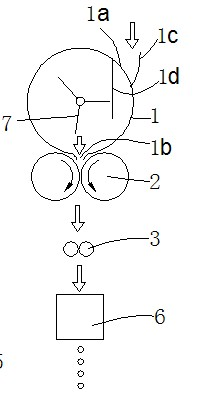

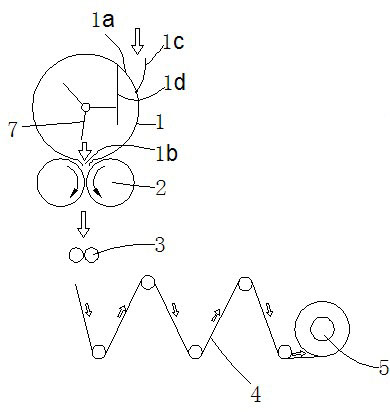

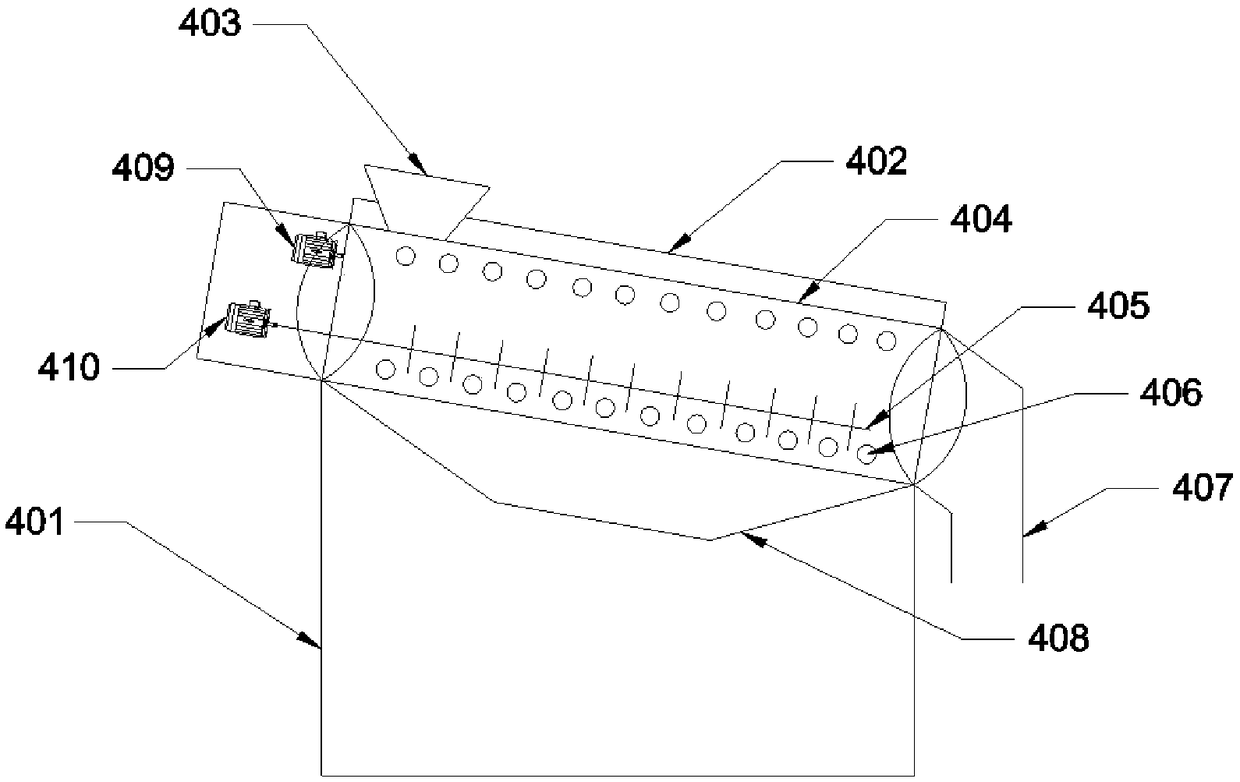

Straw dehydration extrusion forming machine

A straw dehydration extrusion forming machine is used for dehydrating and processing smashed straw into block materials, and is provided with a machine frame; an auger and a material pressing pipelineare installed on the machine frame; the material pressing pipeline is composed of a material pipe and a conical pipe, the material pipe is provided with a feeding inlet, one end of the material pipeis a blind end, the opening of the other end of the material pipe is connected with a flaring flange of the conical pipe, the narrow opening end of the conical pipe is a discharging outlet, and the pipe wall of the conical pipe is provided with a plurality of gas-liquid discharging holes; and the auger is provided with a main shaft, one end of the main shaft is rotationally connected to the machine frame, the other end of the main shaft is arranged in the material pressing pipeline, a shaft body of the main shaft is fixedly connected with a spiral rib sheet, and the axis of the main shaft coincides with that of the conical pipe. The straw block materials which are high in density, small in size and low in water content can be obtained by processing the smashed straw through the straw dehydration extrusion forming machine and can be directly used as fuel for a power plant, storing and transporting are facilitated, and the recycling cost of the straw is reduced.

Owner:磐石市富元机械厂

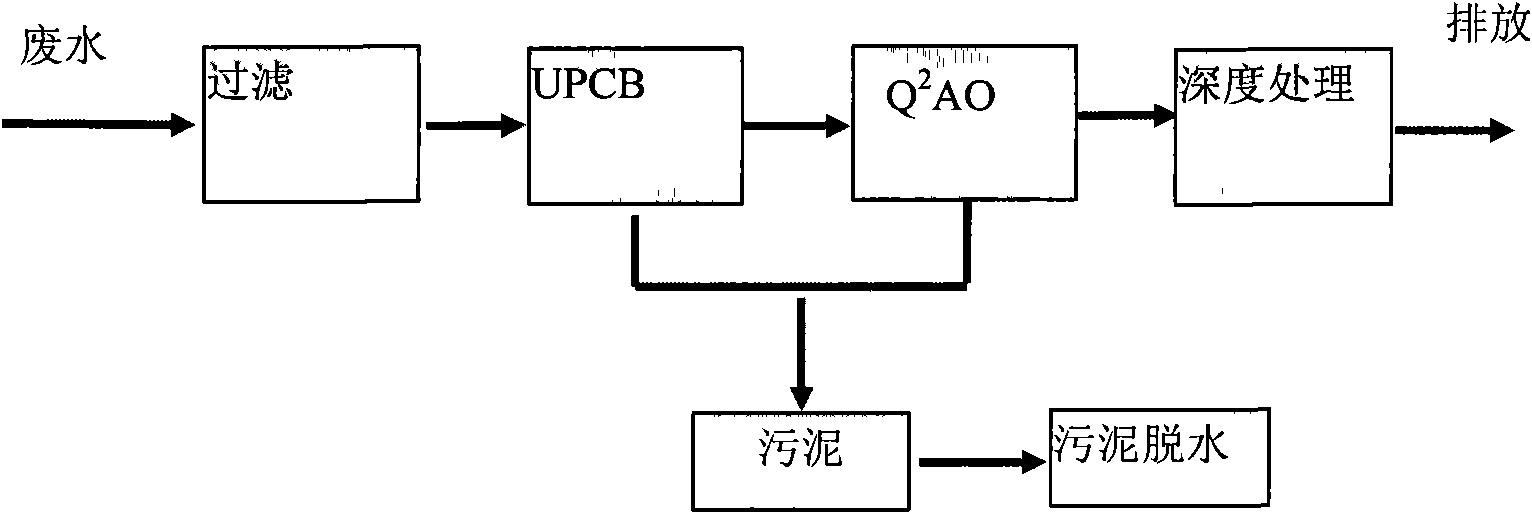

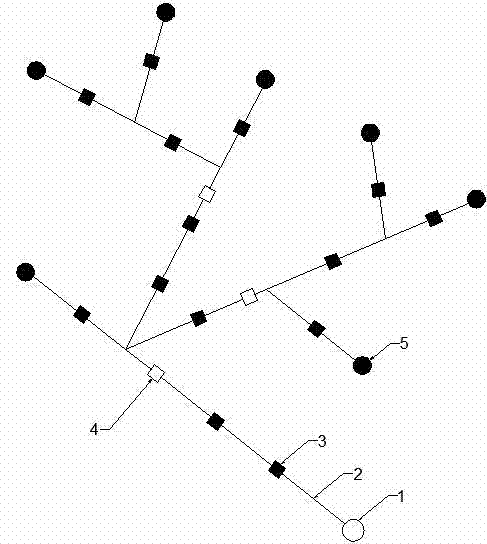

Distributed type sewage treatment system

InactiveCN104843933ATo achieve intensive utilizationReduce land costSludge treatmentMultistage water/sewage treatmentLand resourcesIntelligent management

The invention relates to the technical fields of sewage collection, discharge and sewage treatment, and especially relates to a distributed type sewage treatment system which includes a tree-shaped sewage pipe network, a plurality of sewage treatment base stations in a distributed type arrangement along the tree-shaped sewage pipe network, and sewage treatment devices arranged in the sewage treatment base stations. Compared with the prior art, the distributed type sewage treatment system can significantly save land resources, save the cost of project construction, realize modularization, automation and intelligent management of sewage collection, discharge and sewage treatment and realize sewage classification treatment.

Owner:邓立新

Biomass water-coal-slurry prepared by using livestock breeding wastes

The invention discloses biomass water-coal-slurry prepared by using livestock breeding wastes. The biomass water-coal-slurry is prepared by the following steps: uniformly mixing coal powder, the livestock breeding wastes and water; and adjusting the pH value to 7-9 by sodium hydroxide, wherein the mass ratio of solid matters in the livestock breeding wastes to dry base coal in coal powder is (0.15-1.5) to 100. By replacing additives and part of coal by means of the livestock breeding wastes, the livestock breeding wastes are used as resources, and meanwhile, the use level of coal and water in the pulping process is reduced. The biomass water-coal-slurry has the characteristics of low cost, simple process and environment friendliness. The mass percentage concentration of the obtained biomass water-coal-slurry is not less than 60% and the biomass water-coal-slurry meets the industrial requirements in size distribution, viscosity, pH value and stability.

Owner:XIAN UNVERSITY OF ARTS & SCI +1

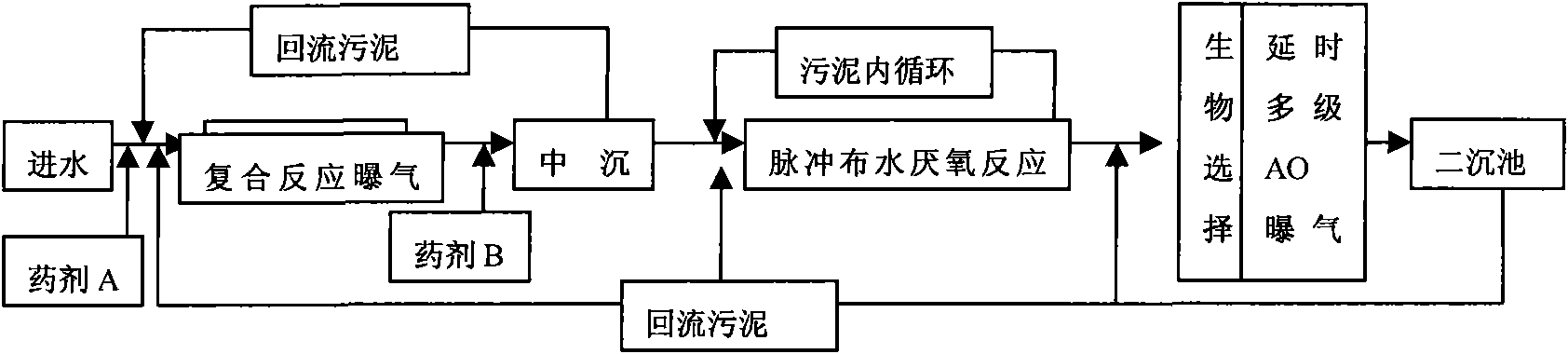

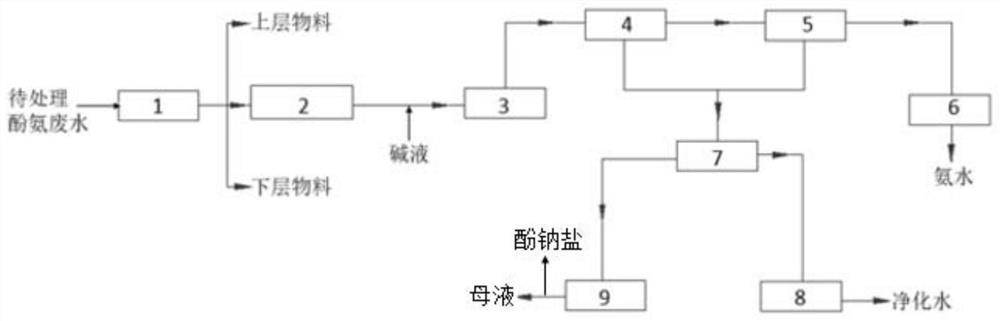

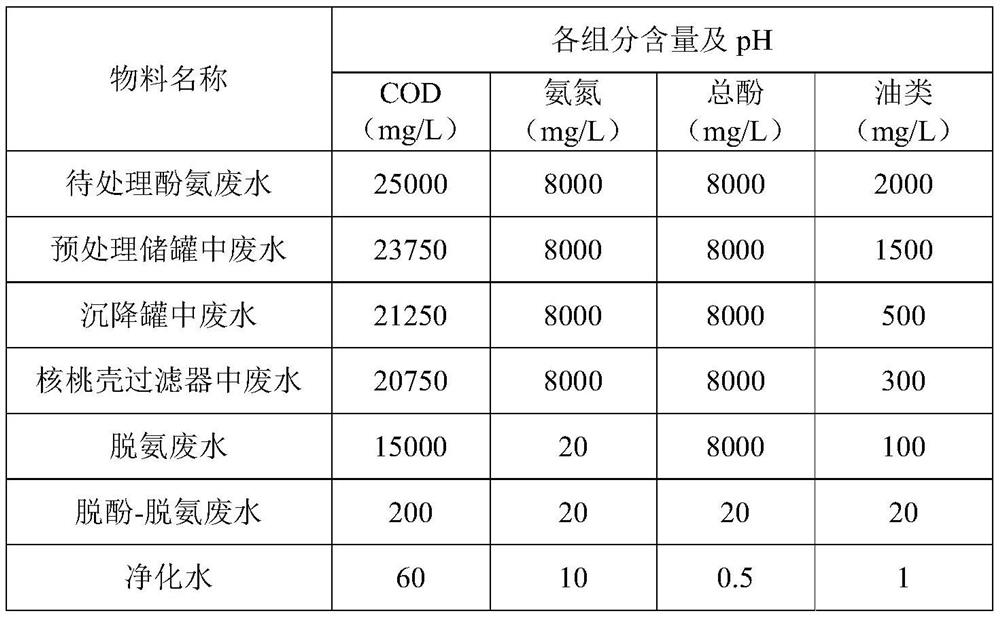

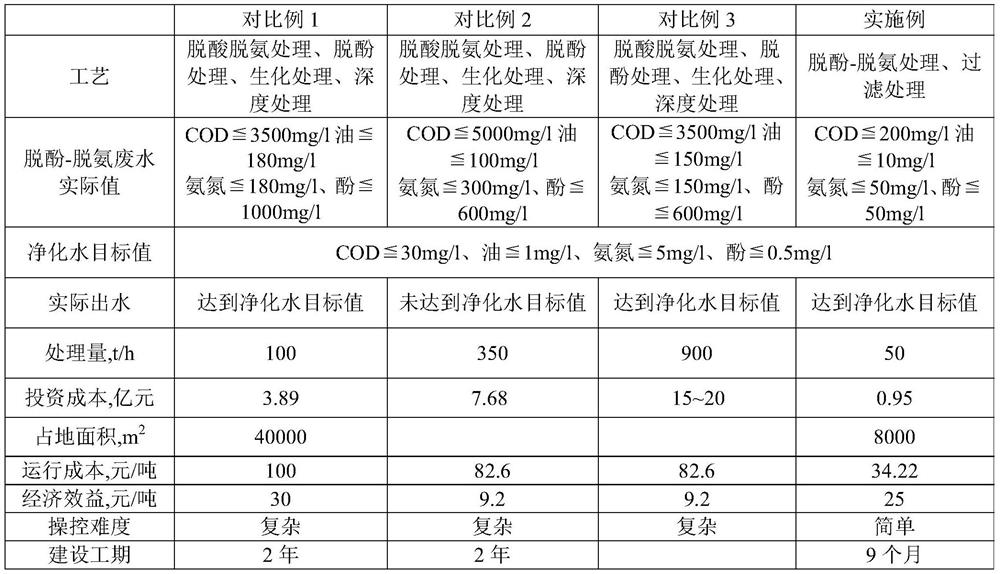

Method and system for treating phenol-ammonia wastewater

ActiveCN112390445AReduce COD contentReduce ammonia nitrogen contentFatty/oily/floating substances removal devicesWater contaminantsSodium PhenolateProcess engineering

The invention relates to a method and system for treating phenol-ammonia wastewater, and the method comprises the following steps: adding an oil removal agent into the phenol-ammonia wastewater to obtain pretreated oil-removed wastewater, further performing deamination treatment on the oil-removed wastewater to obtain deaminated wastewater, and then introducing the obtained deaminated wastewater into an evaporation device to perform dephenolization treatment to obtain dephenolized and deaminated wastewater; and finally, filtering the dephenolized and deaminized wastewater to obtain purified water meeting reuse requirements, wherein ammonia gas, coal tar and sodium phenolate are byproducts at the same time, the reuse cost is low, and the COD content, the ammonia nitrogen content, the totalphenol content and the oil content in reuse water are all low.

Owner:新疆宣力环保能源股份有限公司

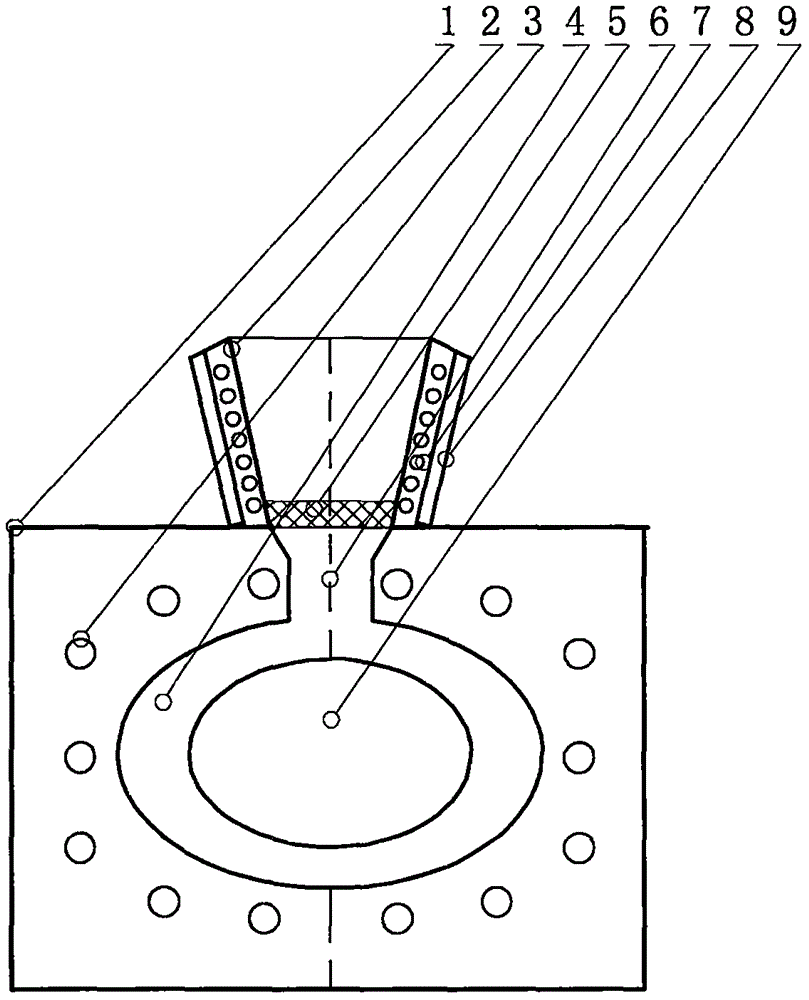

Casting-head-free metal mold

A metal mold for a pouring-free riser is characterized in that it includes a metal mold mechanism and a feeding mechanism; profile; the feeding mouth of the feeding mechanism is set on the left and right molds of the metal mold, divided into left and right parts, the outer wall of the feeding mouth is provided with an electric heater, and the outer wall of the electric heater is provided with a vacuum insulation There is a filter screen in the shell and the feeding port; the feeding mechanism installed on the metal mold is used to replace the existing film-coated sand riser, which can be reused and the cost is low; the electric heater installed on the outer wall of the feeding port is used to control the feeding The feeding port is heated to meet the feeding requirements of the molten metal in the feeding port; the vacuum insulation shell installed on the outer wall of the electric heater is used to insulate the feeding port, which is more energy-saving.

Owner:WUXI LIHU PRESSURIZE TECH CO LTD

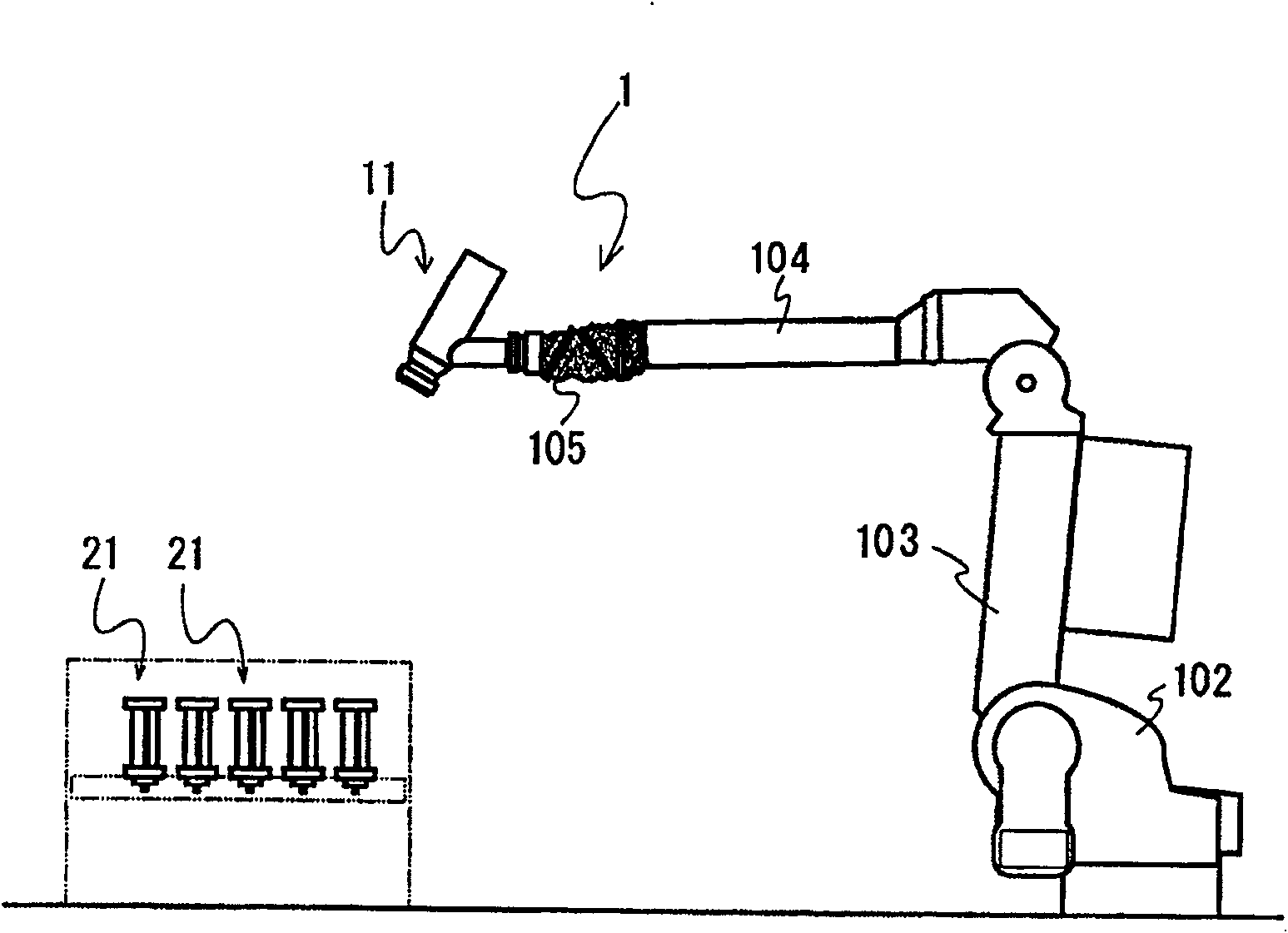

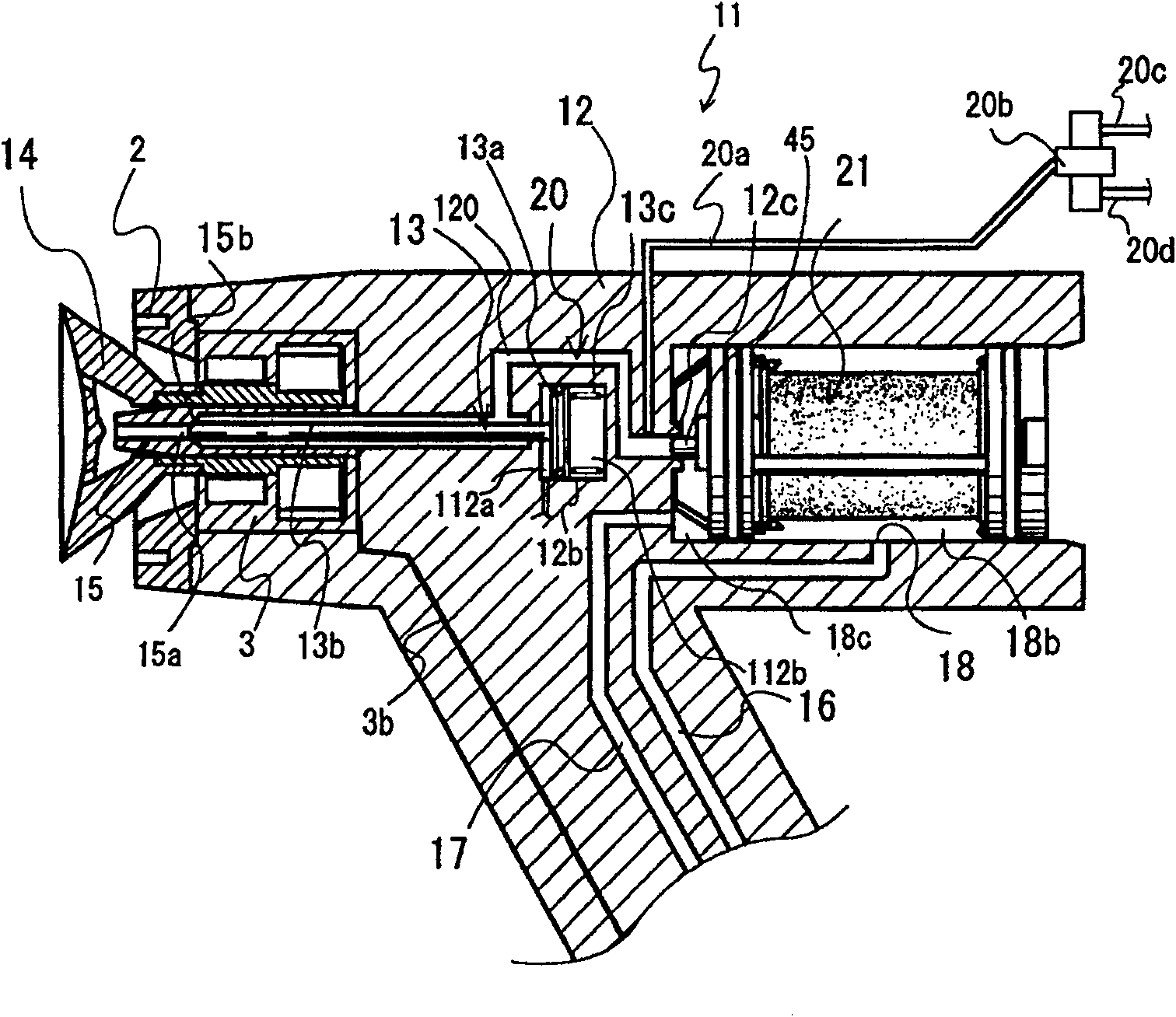

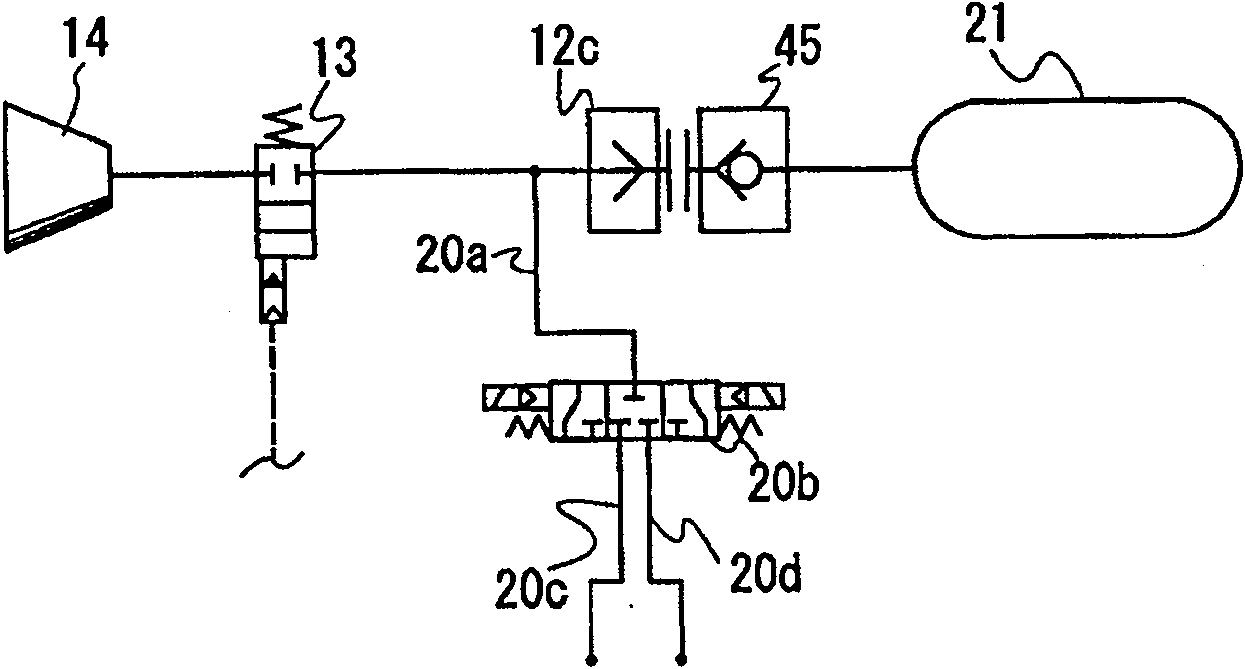

Cartridge-type coating machine and cartridge thereof

InactiveCN100553790CReduce Reuse CostsImprove reusabilityLiquid surface applicatorsLiquid supply arrangementsEngineeringMechanical engineering

The object of the present invention is to provide a cassette paint machine with a painting unit for spraying paint, a simple, light and cheap cartridge for storing paint therein and for supplying paint to this painting unit A cassette is removably mounted to the paint coater. In the painting machine (11), a painting device having a rotary spray head (14) etc. is arranged at the front part of the casing (12), and a cartridge (21) in which paint is stored is detachably mounted to the casing ( 12) back part. The paint in the cartridge (21) is supplied to the rotary spray head (14) by pressurizing the cartridge (21) with a liquid, and the housing (12) and the cartridge (21) form a chamber for storing the liquid Pressurize the solvent storage chamber (18b).

Owner:TOYOTA JIDOSHA KK +1

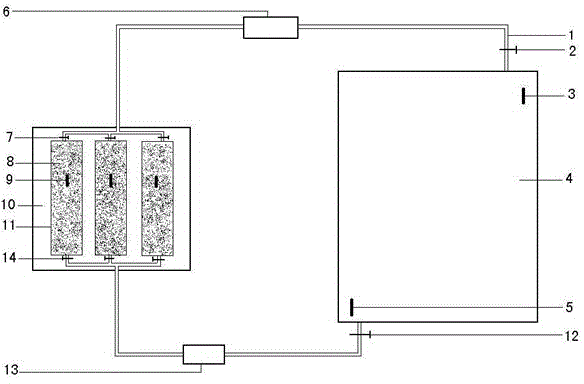

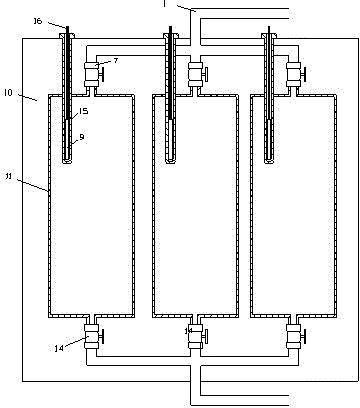

System for reutilizing bromomethane by vacuum heating

InactiveCN102150651BSolve the problem of difficult replacementImprove the desorption effectDispersed particle separationFumigatorsFiberVacuum pumping

The invention relates to a system for reutilizing bromomethane by vacuum heating, which comprises a heating cavity, a closed fumigation facility, a valve, a vacuum pump and pipelines, wherein a plurality of carbon material packed columns are arranged in the heating cavity, and the structure of each carbon material packed column is a cylinder with a cavity; the carbon material packed columns are connected in parallel and communicated; the upper communicating pipeline is led out of the upper part of the heating cavity and then connected with the vacuum pump, passes through the vacuum pump and is further connected to an upper pipeline interface of the closed fumigation facility; the lower communicating pipeline is led out of the lower part of the heating cavity and then connected with a circulating fan, passes through the circulating fan and is further connected to a lower pipeline interface of the closed fumigation facility; the carbon material packed columns adopt the vertical placement, thereby effectively solving the difficult problems of non-uniform distribution of activated carbon or carbon fibers, and difficulty in replacement of the activated carbon or the carbon fibers; the vacuum pump is adopted for vacuum-pumping of the carbon material packed columns, and then the bromomethane adsorbed in carbon material is heated for desorption, thereby improving the desorption effectand reducing the heating desorption temperature; and the bromomethane which is desorbed by vacuum heating can be directly discharged to the fumigation facility with goods to be fumigated, thereby reducing the reutilizing cost of the bromomethane.

Owner:中华人民共和国天津出入境检验检疫局

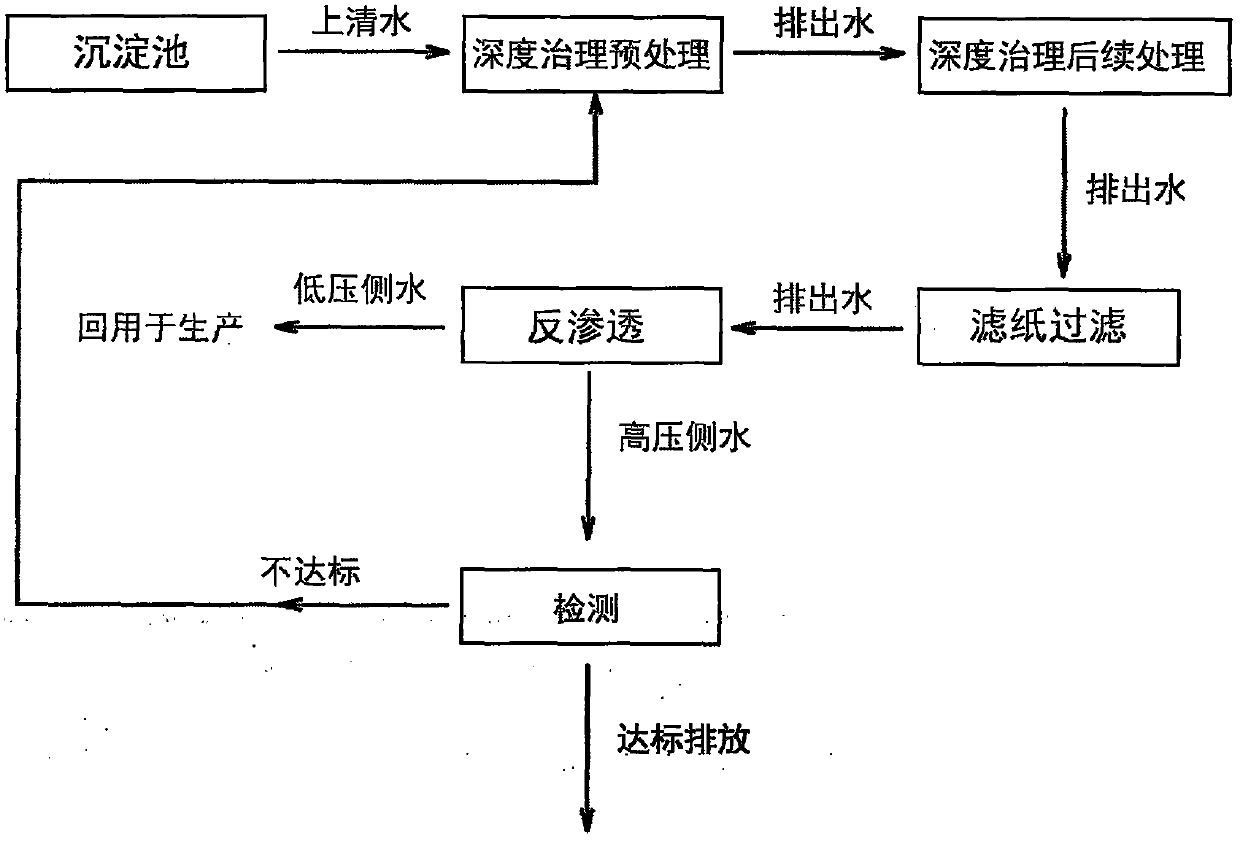

A recycling process of electroplating wastewater

ActiveCN105645632BImprove water qualityStable water volumeWater contaminantsTreatment involving filtrationWater qualityReverse osmosis

The invention discloses a process for recycling electroplating wastewater. The process comprises the following steps: (1) carrying out advanced-treatment pretreatment on the electroplating wastewater; (2) carrying out advanced-treatment aftertreatment on discharge water; (3) enabling treated wastewater to flow through filter paper so as to filter the treated wastewater; (4) pumping the wastewater into reverse-osmosis equipment; (5) carrying out detecting. By adopting the wastewater recycling process disclosed by the invention, requirements of the reverse-osmosis equipment on influent water quality can be met, the water quality of recycled water is stable, normal operation for the reverse-osmosis equipment can be ensured, the reverse-osmosis equipment can normally work for 10 months and even longer than 1 year, and meanwhile, the wastewater of a high-pressure side can be discharged after reaching standard.

Owner:余美媟

Method and equipment for recovering machine head material of plastic extruder/injection molding machine on site

The invention discloses a method and equipment for recovering machine head material of a plastic extruder / an injection molding machine on a site. The method comprises the following steps of: preserving heat in a heating way, pressing a plate, batten, dicing or winding after cooling. The equipment comprises a heating insulation can, a plate pressing machine and a plodder, wherein the heating insulation can, the plate pressing machine and the plodder are distributed from up to down in an assembly line, a material transporting port and a material discharging port are arranged on the heating insulation can, the machine head material sequentially passes through the heating insulation can, the plate pressing machine and the plodder, and are diced into grains by a dicing machine, or are drawn onto a wire spool by a tractor to be wound into coils. The invention skillfully processes the machine head material by a noodle processing method and equipment, so that the on-site recovery problem of the machine head material of the plastic extruder / the injection molding machine can be effectively solved, the invention has the characteristics of energy saving, lower cost and convenience in recovery, and the use performance of the machine head material can be simultaneously guaranteed.

Owner:陈蕴

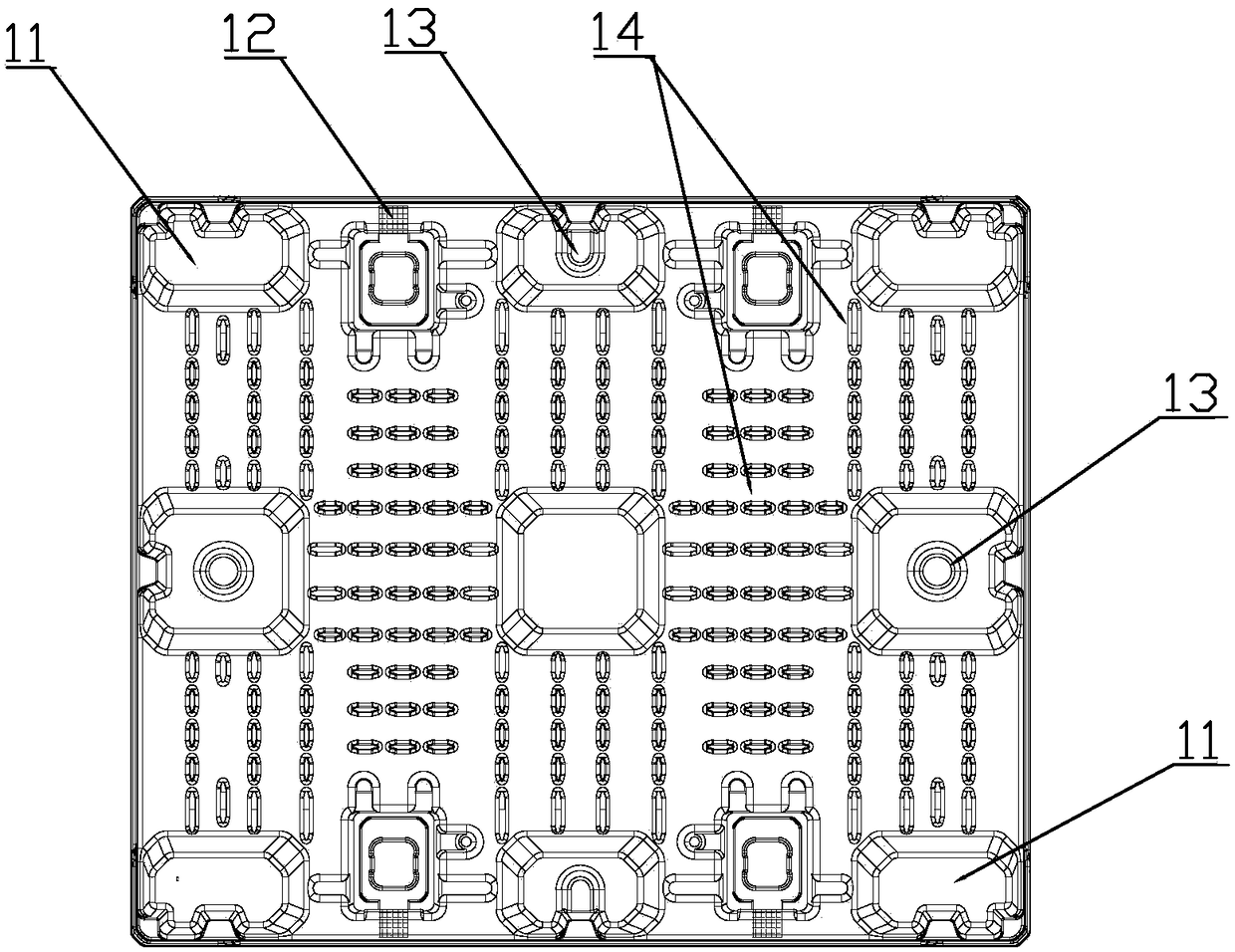

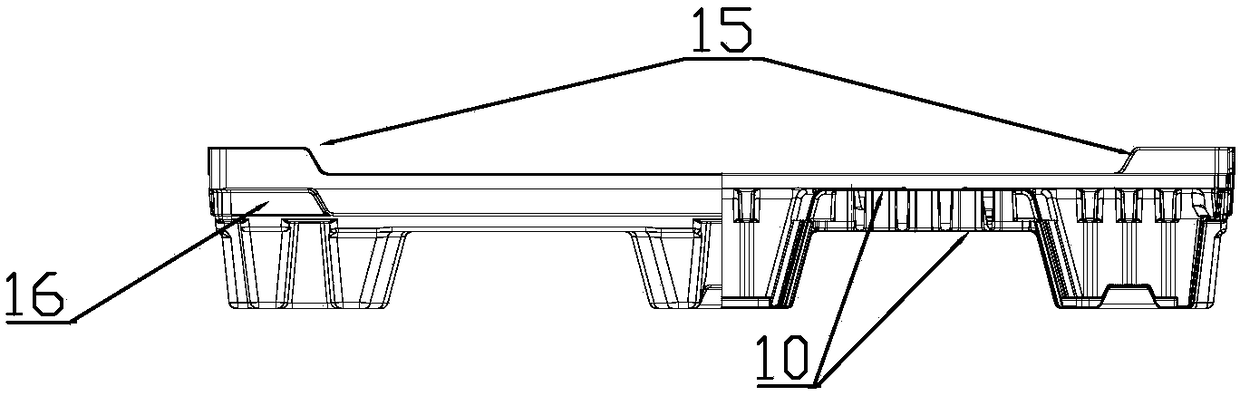

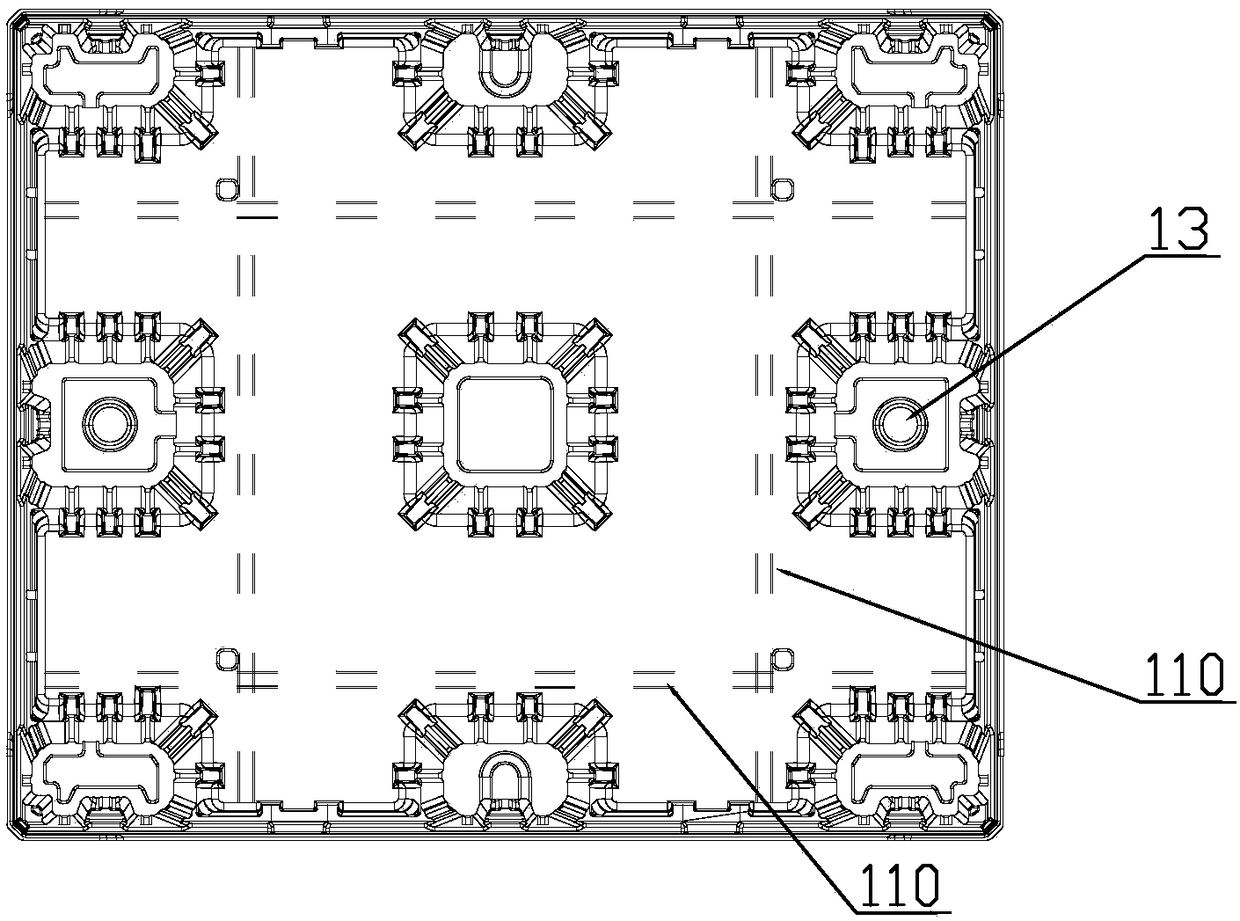

Double-layer plastic-absorption top-and-bottom cover of folding enclosing plate box

PendingCN108202897ASimple structureEasy to cleanPackage recyclingRigid containersGroundcoverEngineering

The invention discloses a double-layer plastic-absorption top-and-bottom cover of a folding enclosing plate box. The double-layer plastic-absorption top-to-bottom cover comprises a double-layer groundcover, a double-layer top cover and a folding enclosing plate; the double-layer ground cover and the double-layer ground cover are formed by combining plastic-absorbing materials and well-shaped square tubes through double-layer plastic-absorption mode, nine foot piers are arranged on the double-layer ground cover, limiting flanges are arranged at the upper part of the corner of the double-layerground cover, nested limiting tables are arranged on the lower portions of the lower part of the corner of the double-layer ground cover; the double-layer top cover is formed through a plurality of circular rib holes which are uniformly distributed in a double-layer plastic-absorbing mode; and the folding enclosing plate, the double-layer ground cover and the double-layer top cover form an enclosing plate box body by enclosing plate limiting grooves. The double-layer top cover and the double-layer ground cover are machined through double-layer plastic-absorbing processing, and the overall comprehensive strength is increased by arranging the U-shaped square tubes, waist-shaped ring ribs and round rib holes; the double-layer plastic-absorption top-and-bottom cover is simple in structure, firm, durable, easy to clean and low in repeated use cost, and the integral recycling or three-in-one stacking and recycling can be carried out in a nested mode; and the recovery ratio is high, the overall bearing capacity is large, and the requirements of different customers can be better met.

Owner:江苏鑫广才包装材料有限公司

A kind of extraction method of ferulic acid in rice bran meal

ActiveCN107190028BReduce Reuse CostsReduce pollutionHydrolasesFermentationCross-linkFeruloyl esterase

The invention discloses an extraction method for ferulic acid in rice bran meal. According to the method, cross-linking fixation is carried out on biomagnetic nanometer materials such as magnetosome and feruloyl esterase by adopting transglutaminase so as to obtain immobilized feruloyl esterase, then ferulic acid ester in rice bran meal after rice bran oil is extracted is pretreated by adopting the immobilized feruloyl esterase, extraction is carried out by using isopropyl alcohol after pretreatment, after solid-liquid separation of the extracting solution, then microfiltration and nanofiltration two-stage decontamination and low-temperature vacuum concentration are adopted, and activated carbon decoloration and recrystallization carried out on concentrated solution, so that a ferulic acid product with the purity of more than 98% is obtained. Natural ferulic acid is extracted from rice bran meal by adopting the immobilized feruloyl esterase, so that the problems of environmental pollution, low safety and high industrialized production cost existing in the prior art are overcome, and the extraction method has preferable application prospects.

Owner:XIAN HEALTHFUL BIOTECH

Extraction method for ferulic acid in rice bran meal

ActiveCN107190028ALow reuse costReduce environmental pollutionHydrolasesFermentationChemistryActivated carbon

The invention discloses an extraction method for ferulic acid in rice bran meal. According to the method, cross-linking fixation is carried out on biomagnetic nanometer materials such as magnetosome and feruloyl esterase by adopting transglutaminase so as to obtain immobilized feruloyl esterase, then ferulic acid ester in rice bran meal after rice bran oil is extracted is pretreated by adopting the immobilized feruloyl esterase, extraction is carried out by using isopropyl alcohol after pretreatment, after solid-liquid separation of the extracting solution, then microfiltration and nanofiltration two-stage decontamination and low-temperature vacuum concentration are adopted, and activated carbon decoloration and recrystallization carried out on concentrated solution, so that a ferulic acid product with the purity of more than 98% is obtained. Natural ferulic acid is extracted from rice bran meal by adopting the immobilized feruloyl esterase, so that the problems of environmental pollution, low safety and high industrialized production cost existing in the prior art are overcome, and the extraction method has preferable application prospects.

Owner:XIAN HEALTHFUL BIOTECH

System for separating plastic from city garbage

The invention discloses a system for separating plastic from city garbage. The system comprises a magnetic separation device, a drying device, a screening device, a smashing device, a wind power shaking table separation device and an electrostatic separation device in sequence. The processes of household garbage, magnetic separation, drying, screening, smashing, wind power shaking table separation, electrostatic separation and waste plastic are implemented. 95% or above of plastic in the household garbage is separated, the separated plastic has higher purity, the content of impurities in the plastic is very low, the waste garbage is recycled more conveniently in the future, the recycle cost is saved, and the problem caused by impure raw materials in the reprocessing process is solved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

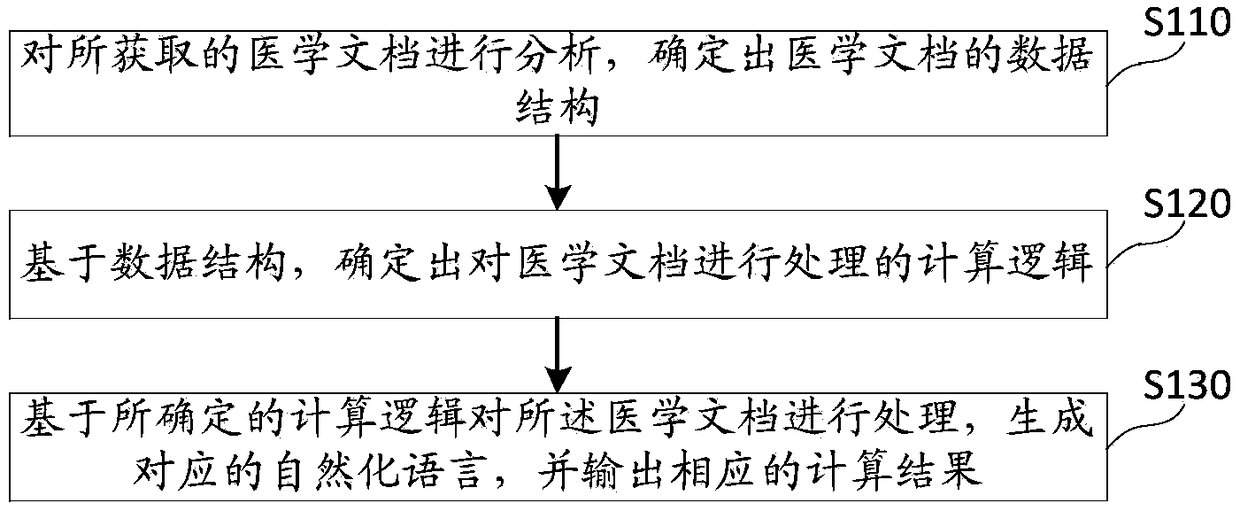

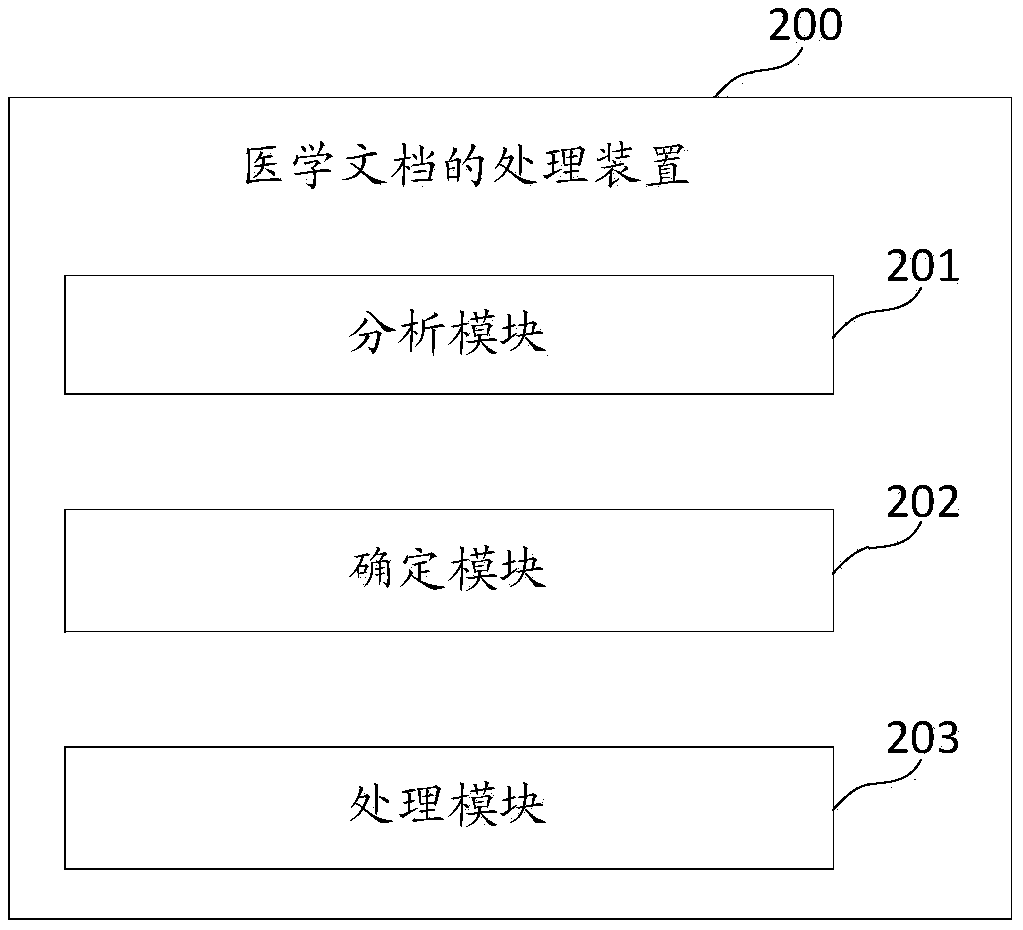

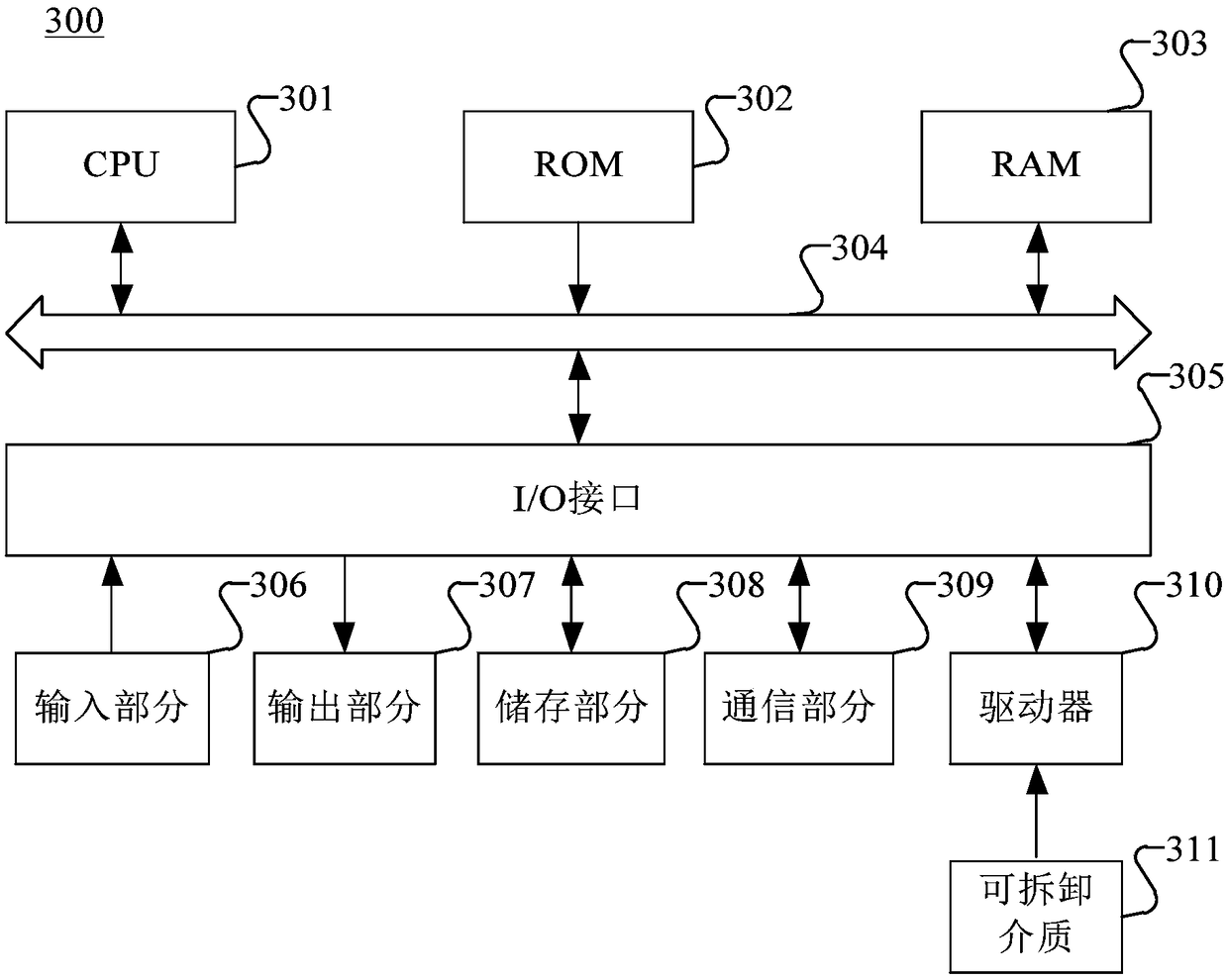

Medical document processing method, device, medium and electronic device

ActiveCN109299475AAvoid duplicationReduce Reuse CostsNatural language data processingSoftware reuseComputational logicDocumentation

The embodiment of the invention provides a processing method, a device, a medium and an electronic device of a medical document. The processing method of the medical document comprises the following steps: analyzing the obtained medical document to determine a data structure of the medical document; Based on the data structure, the computational logic of medical document processing is determined.The medical document is processed based on the determined computational logic, a corresponding naturalized language is generated, and a corresponding computational result is outputted. The technical proposal of the embodiment of the invention provides a universal, naturalized language for describing the calculation logic and the process, avoids writing the code repeatedly, only needs to write thecalculation language and submit to the calculation frame, and the user can customize the basic calculation logic, thereby reducing the code reuse cost.

Owner:GOLDEN PANDA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com