Porous catalytic material and preparation method

A catalytic material and microporous technology, applied in the field of multi-structured porous catalytic materials and their preparation, can solve the problems of increasing filtrate and waste residue treatment costs, high recycling costs, and increasing the cost of production, reducing preparation costs, promoting pre-cracking, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

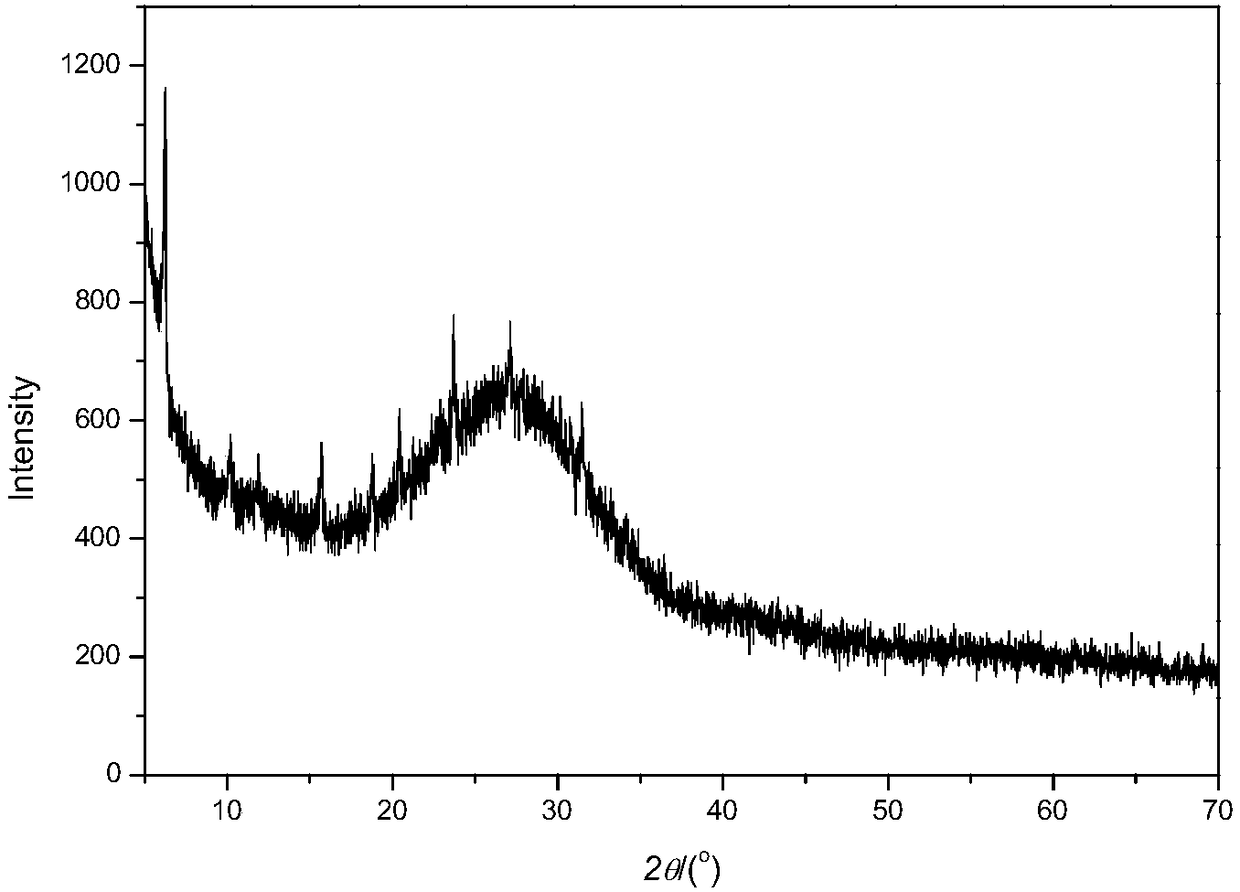

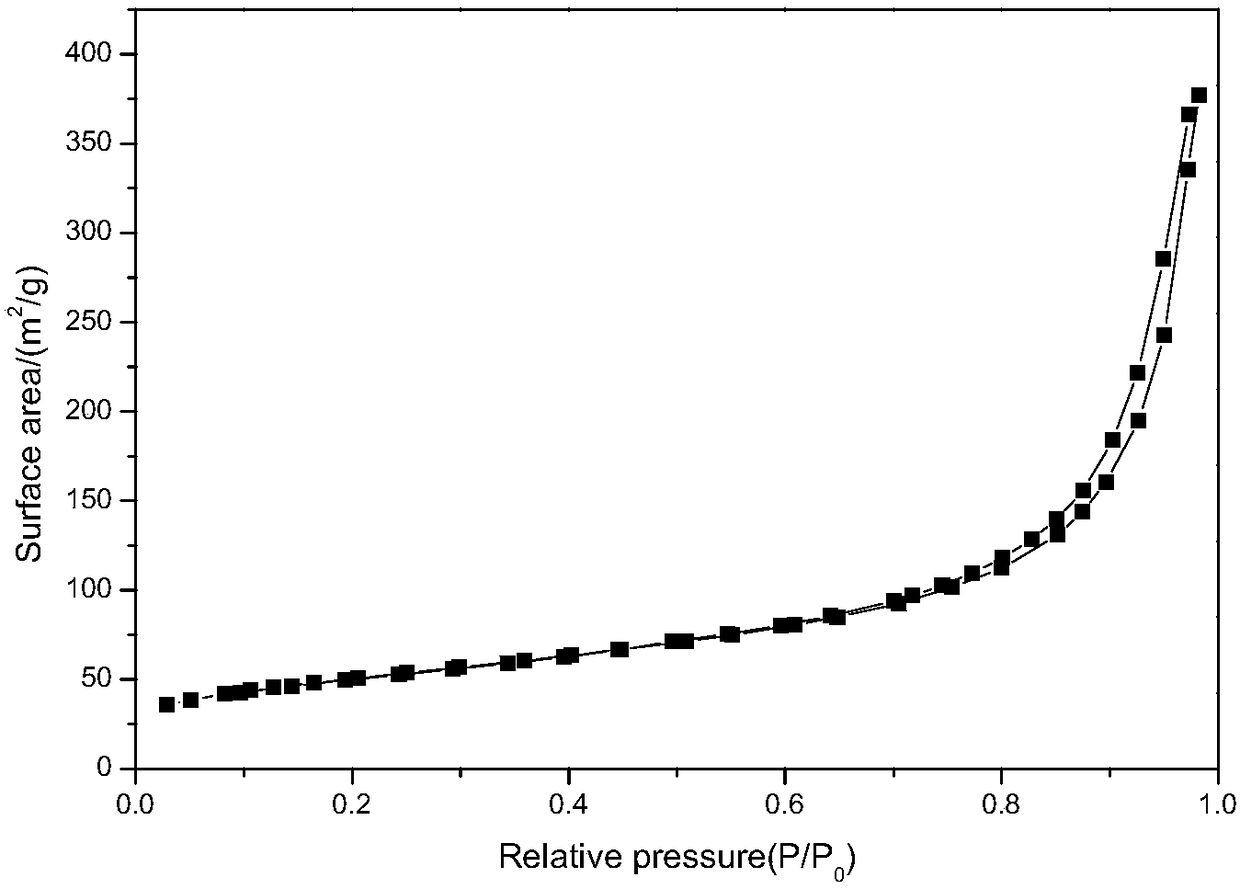

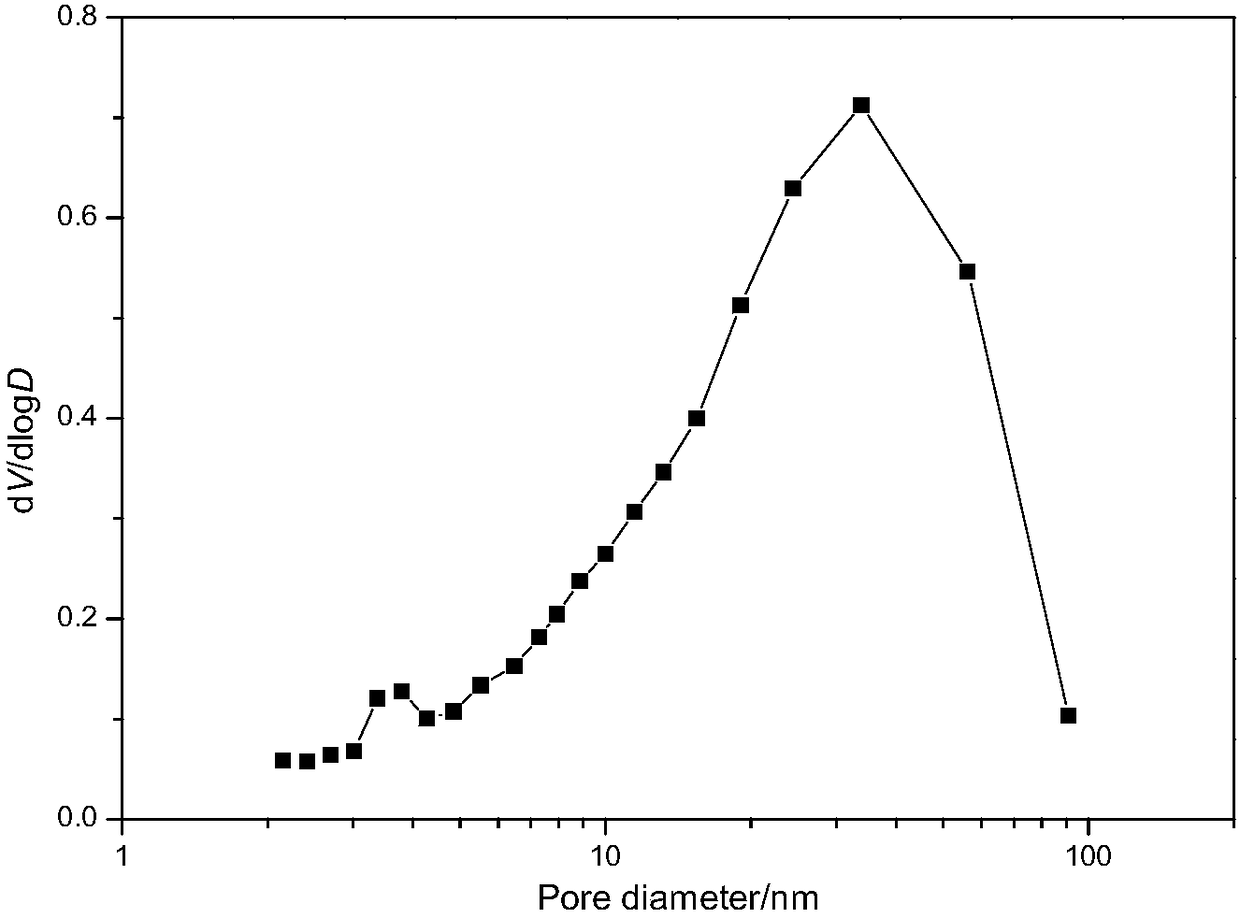

Image

Examples

Embodiment 1

[0035] This example illustrates the catalytic material of the present invention and its preparation process.

[0036] First add a small amount of deionized water in the container, and under room temperature and vigorous stirring, the NaY molecular sieve crystallization mother liquor (concentration 55gSiO 2 / L, suspended matter concentration 39mg / L) and sodium metaaluminate solution (186 gAl 2 o 3 / L, caustic ratio 2.45) is simultaneously added into the container in a co-current manner to form a gel continuously, and the pH value is controlled to be 13.7; then the metered AlCl is added 3 Solution (concentration 60gAl 2 o 3 / L) and adjust the pH value of the slurry to 9.7, heat up to 55°C and treat at a constant temperature for 2 hours; filter the resulting solid precipitate according to the dry basis of the precipitate: ammonium salt: H 2 The weight ratio of O=1:0.6:10 was exchanged at 55° C. for 0.5 hour, repeated exchange once, filtered and washed with water to obtain the...

Embodiment 2

[0045] This example illustrates the catalytic material of the present invention and its preparation process.

[0046] First, a small amount of deionized water was added to the container and the temperature was raised to 40°C, and the NaY molecular sieve crystallization filtrate (concentration 20gSiO 2 / L, suspended matter concentration 98mg / L) and sodium metaaluminate solution (159 gAl 2 o 3 / L, caustic ratio 1.65) is simultaneously added into the container in a co-current manner to form a gel continuously, and the pH value is controlled to be 13.5; then added metered Al 2 (SO 4 ) 3 Solution (concentration 90gAl 2 o 3 / L) and adjust the pH of the slurry to be 10.1, heat up to 80°C and treat at a constant temperature for 4 hours; filter the resulting solid precipitate according to the dry basis of the precipitate: ammonium salt: H 2 The weight ratio of O=1:0.7:10 was exchanged at 60° C. for 0.5 hour, repeated exchange once, filtered and washed with water to obtain the cat...

Embodiment 3

[0051] This example illustrates the catalytic material of the present invention and its preparation process.

[0052] First, a small amount of deionized water was added to the container and the temperature was raised to 50°C, and the NaY molecular sieve crystallization filtrate (concentration 41gSiO 2 / L, suspended matter concentration 2112mg / L) and sodium metaaluminate solution (102gAl 2 o 3 / L, caustic ratio 2.55) is simultaneously added into the container in a parallel flow mode to form gel continuously, and the pH value is controlled to be 13.4; then add metered Al(NO 3 ) 3 Solution (concentration 60gAl 2 o 3 / L) and adjust the pH value of the slurry to 9.0, continue to treat at a constant temperature at 50°C for 8 hours; filter the resulting solid precipitate according to the dry basis of the precipitate: ammonium salt: H 2 The weight ratio of O=1:1:12 was exchanged at 70° C. for 1 hour, filtered and washed with water to obtain the catalytic material provided by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com