Cartridge-type coating machine and cartridge thereof

一种涂漆机、卡盒的技术,应用在其卡盒领域,能够解决卡盒数量大、增大成本、卡盒不再有用等问题,达到大小降低、成本降低、降低再利用成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

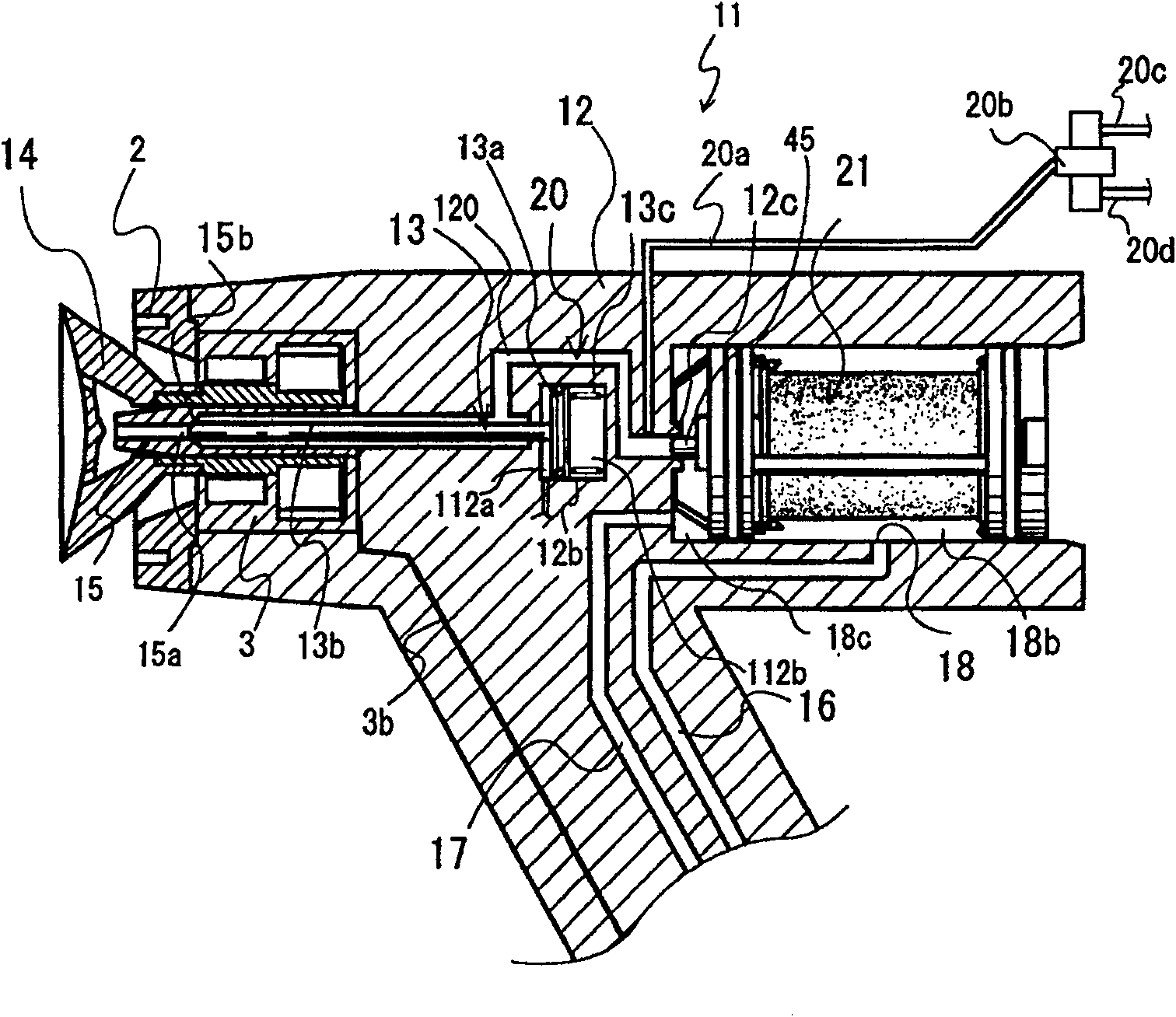

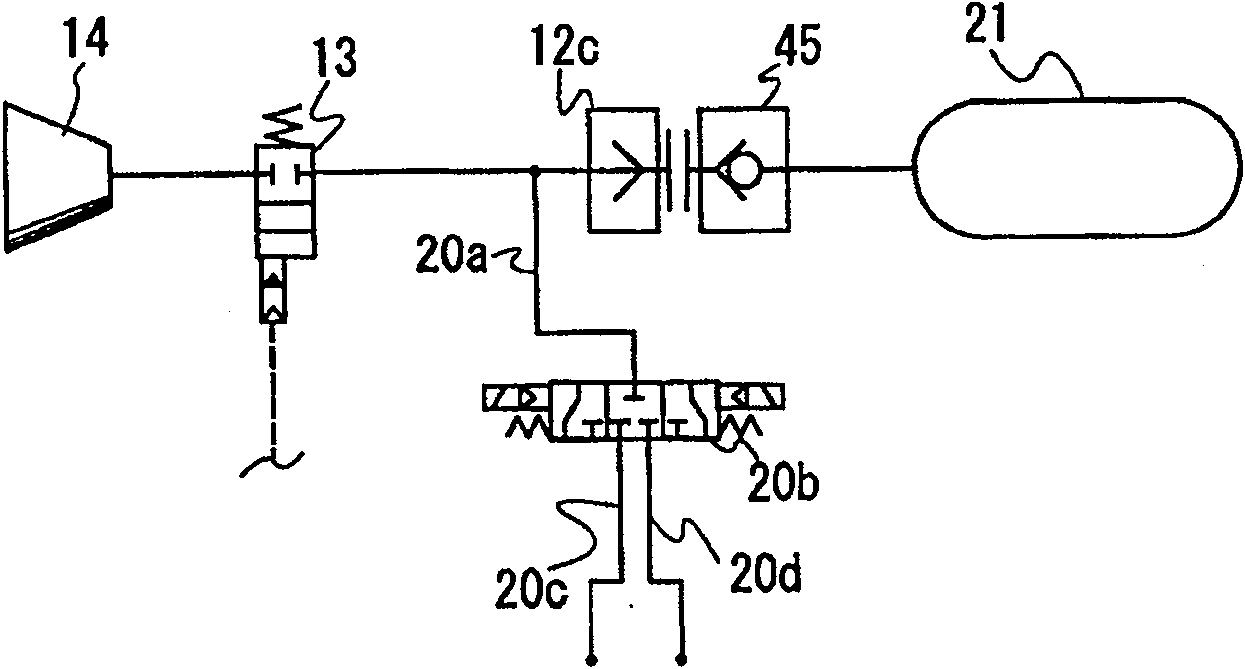

[0056] Embodiments of the present invention will be explained with reference to the drawings.

[0057] Paint manipulator

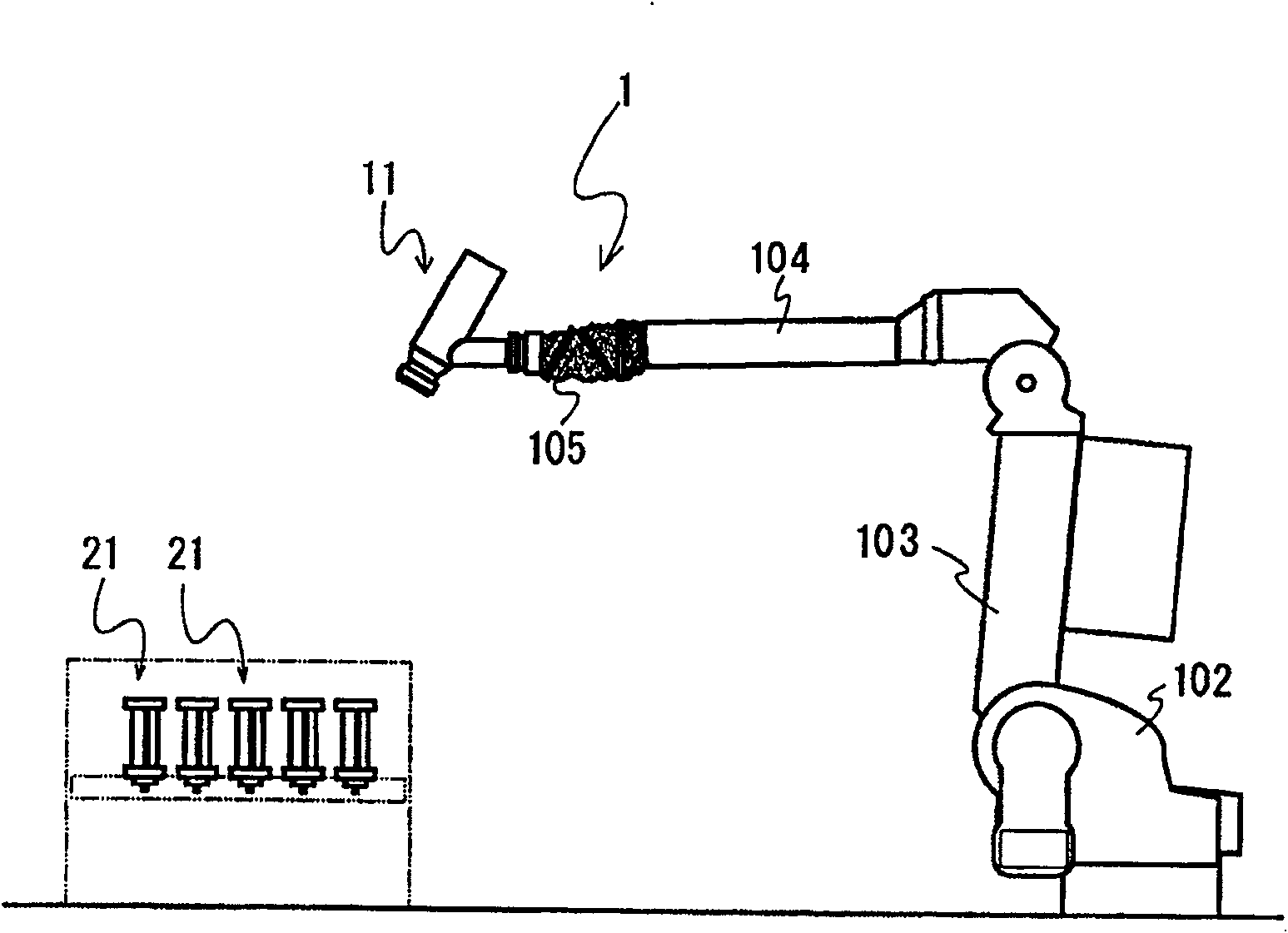

[0058] First, an explanation will be given of an exemplary configuration of a painting robot 1 provided with a cassette type paint machine according to the present invention.

[0059] figure 1 A painting robot 1 provided with a cassette painting machine according to the invention is illustrated.

[0060] The painting robot 1 includes a base 102 , a vertical arm 103 rotatably and swingably provided on the base 102 , an arm 104 swingably provided at the top end of the vertical arm 103 , and a joint portion 105 provided at the top end of the arm 104 . The cassette type rotary spray paint machine 11 is configured at the joint portion 105 .

[0061] The paint machine 11 is provided with an exchangeable cartridge 21 in which paint is stored. A switch (not shown) automatically exchanges the cassette 21 with another cassette 21 conveyed from the storage locati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com