Sewage treatment method for fluorite concentration plant

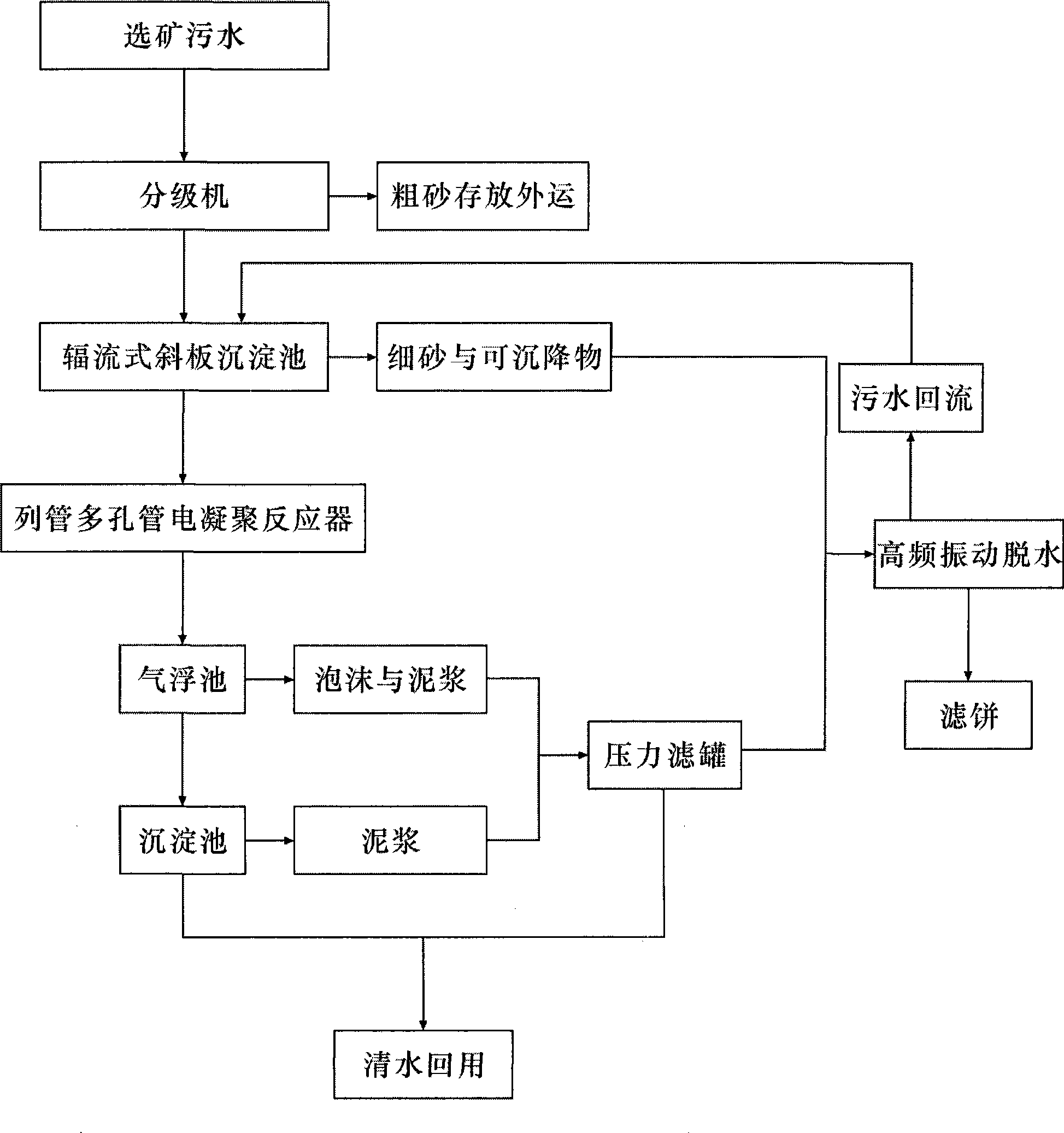

A sewage treatment method and the technology of a concentrator, applied in the direction of flotation water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of increased reuse costs, high tailings storage costs, high treatment costs, etc. problem, to achieve the effect of small footprint, wide application range, and improved removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] 1. Grading sedimentation: The sewage is graded and sedimented according to the thickness of the sediment particles. The equipment used is a classifier and a radial flow sinking and floating tank

[0040] ①The working principle of the classifier, the sewage enters the sedimentation area of the classifier after being rectified and energy-dissipated from the side of the classifier, and the coarse sand settles to the bottom by gravity, and then is conveyed to a high place inclined at 15° by the rotating screw shaft at 5 revolutions per minute. Dehydration, the sewage is discharged from the overflow port.

[0041] ② Radial flow sinking and floating tank, the sewage enters from the center of the tank because the diameter is much larger than the depth. The water flows radially to the surroundings, and the sewage after sedimentation is discharged back to the solid collection tank. The sludge slowly enters the sludge hopper in the center of the pool under the action of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com