Removal method for dissolved oxygen in recycled water

A technology of dissolved oxygen and high-pressure water, applied in chemical instruments and methods, water pollutants, degassed water/sewage treatment, etc., to achieve low operating costs, improve catalytic reduction performance, and promote uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The raw activated carbon fibers were cut into small cubes of 0.5 cm × 0.5 cm, boiled in a boiling water bath for 30 min, the surface was rinsed with deionized water, repeated 3 times, and dried in a drying oven, recorded as ACF.

[0042] Take 5g of pretreated activated carbon fiber, put it in a high-pressure reaction kettle, add 200ml of deionized water, seal it, and raise the temperature to 270°C for pressurized hydrothermal modification for 3h. The modified activated carbon fiber was taken out after cooling down, and dried in an electric blast drying oven at 105°C to constant weight, which was denoted as GSACF.

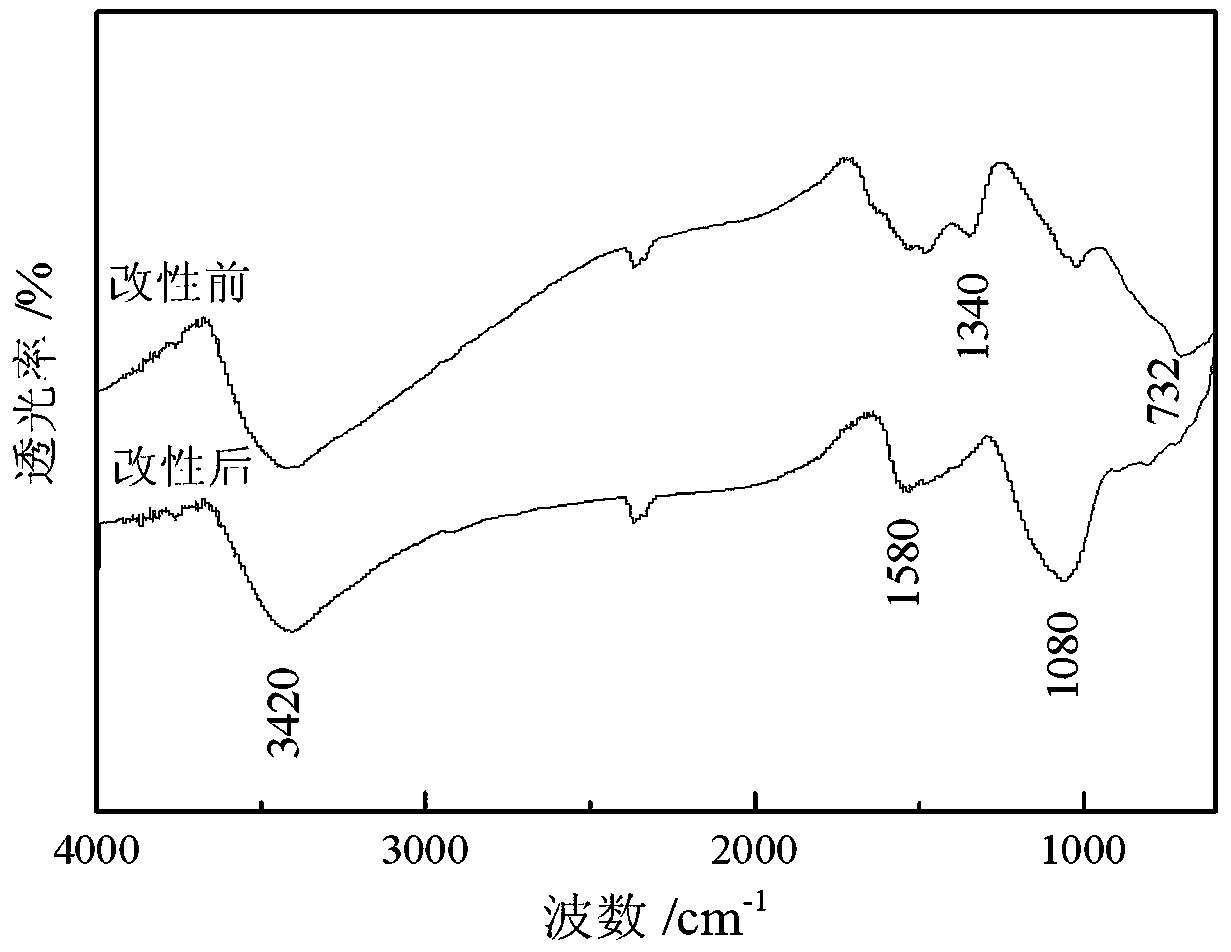

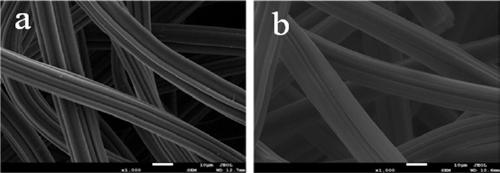

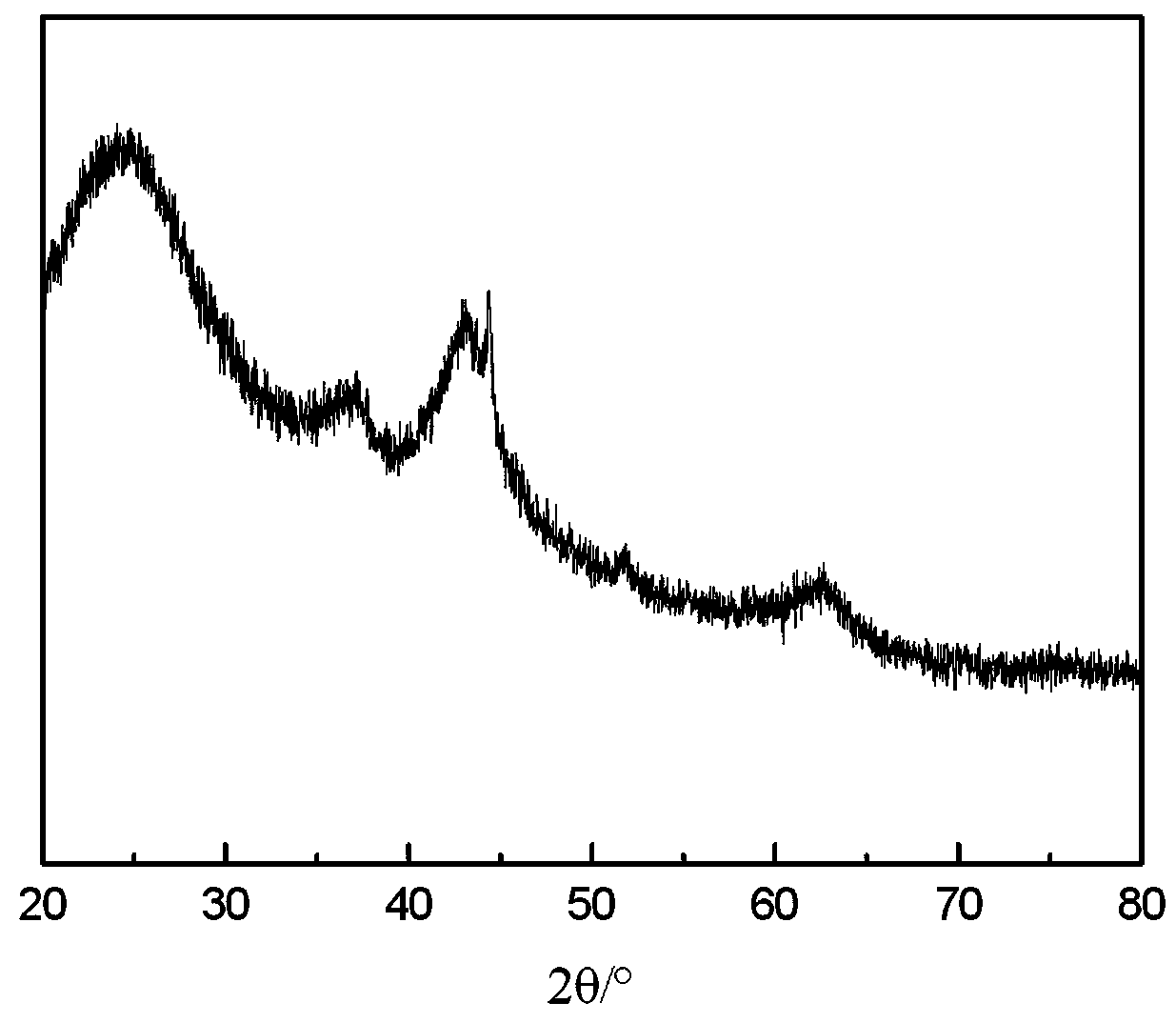

[0043] figure 1 The infrared spectra of activated carbon fibers and modified activated carbon fibers are given. 3450-3400cm in the picture -1 The absorption peak at is attributed to -OH stretching vibration, 1580cm -1 The absorption peak at is attributed to C=O stretching vibration, 1340cm -1 The absorption peak at is attributed to the C-H bending vibrati...

Embodiment 2

[0049] Take 5g of pretreated activated carbon fiber, put it in a high-pressure reaction kettle, add 200ml of deionized water, seal it, and raise the temperature to 300°C for pressurized hydrothermal modification for 2h. The modified activated carbon fiber was taken out after cooling down, and dried to constant weight in an electric blast drying oven at 105°C.

[0050] Ni(NO 3 ) 2 As a precursor material, the precursor solution was prepared according to the theoretical copper loading of 8wt%, dropped into the modified activated carbon fiber at 16ml / g, ultrasonically treated for 30min, placed in a constant temperature oscillator, and oscillated under the conditions of 25°C and 150r / min 3h, after drying to constant weight at 105°C, put it in a quartz tube, under N 2 The combined modified activated carbon fiber catalyst was prepared by heating to 300°C and calcining for 3 h under atmosphere.

Embodiment 3

[0052] Take 5g of pretreated activated carbon fiber, put it in a high-pressure reactor, add 200ml of deionized water, seal it, raise the temperature to 250°C and pressurize hydrothermal modification for 2.5h. The modified activated carbon fiber was taken out after cooling down, and dried to constant weight in an electric blast drying oven at 105°C.

[0053] Ni(NO 3 ) 2 As a precursor material, the precursor solution was prepared according to the theoretical zinc loading of 15wt%, dropped into the modified activated carbon fiber at 16ml / g, ultrasonically treated for 30min, placed in a constant temperature oscillator, and oscillated under the conditions of 25°C and 150r / min 3h, after drying to constant weight at 105°C, put it in a quartz tube, under N 2 The combined modified activated carbon fiber catalyst was prepared by heating to 350°C and calcining for 2 h under atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com