Soil-retaining dam and construction method thereof

A technology for dam body and waste tires, which is applied in the direction of filling, dam, wall dam, etc., can solve the problems of secondary pollution, etc., and achieve the effects of stable structure, fast processing speed and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

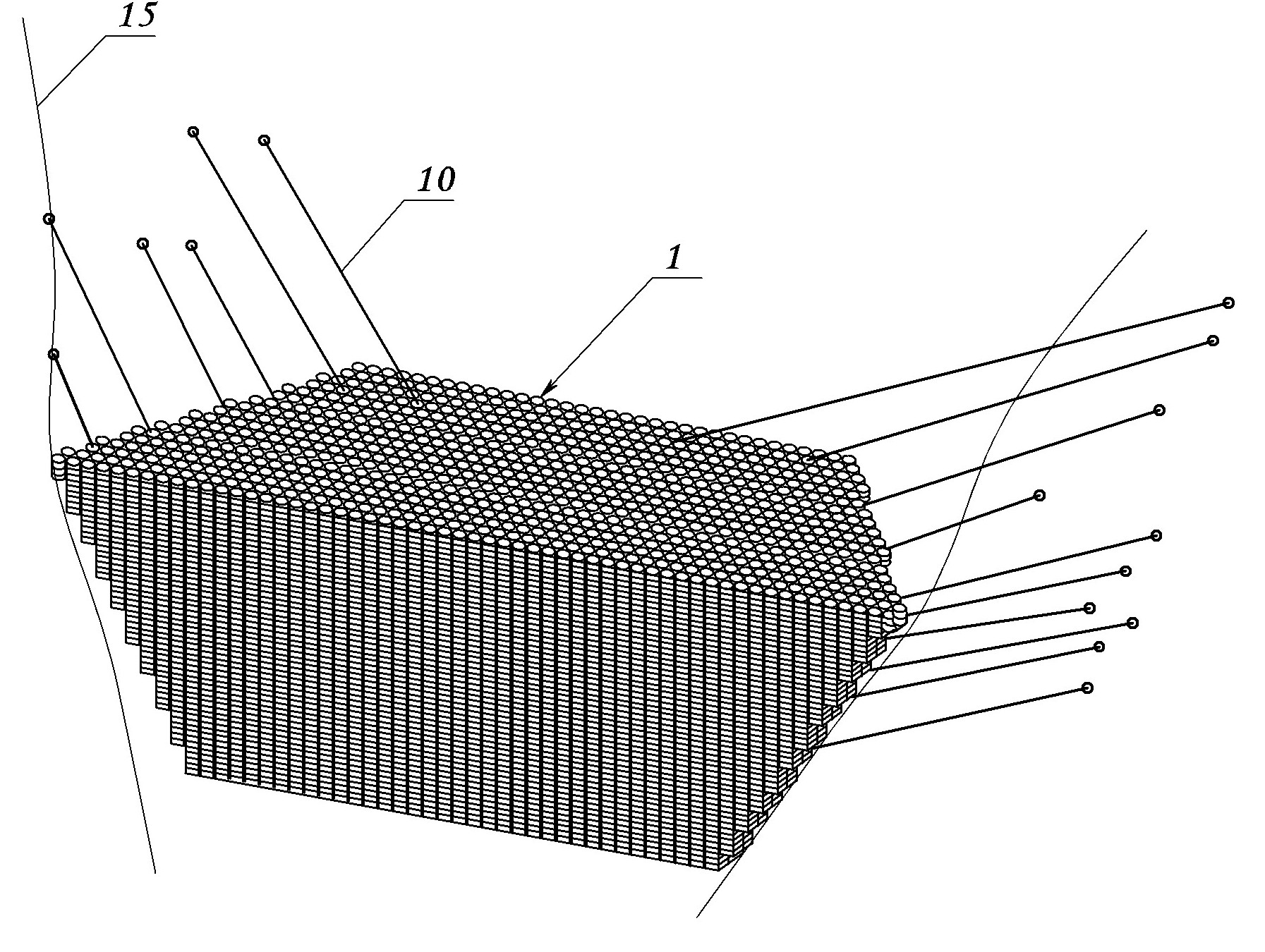

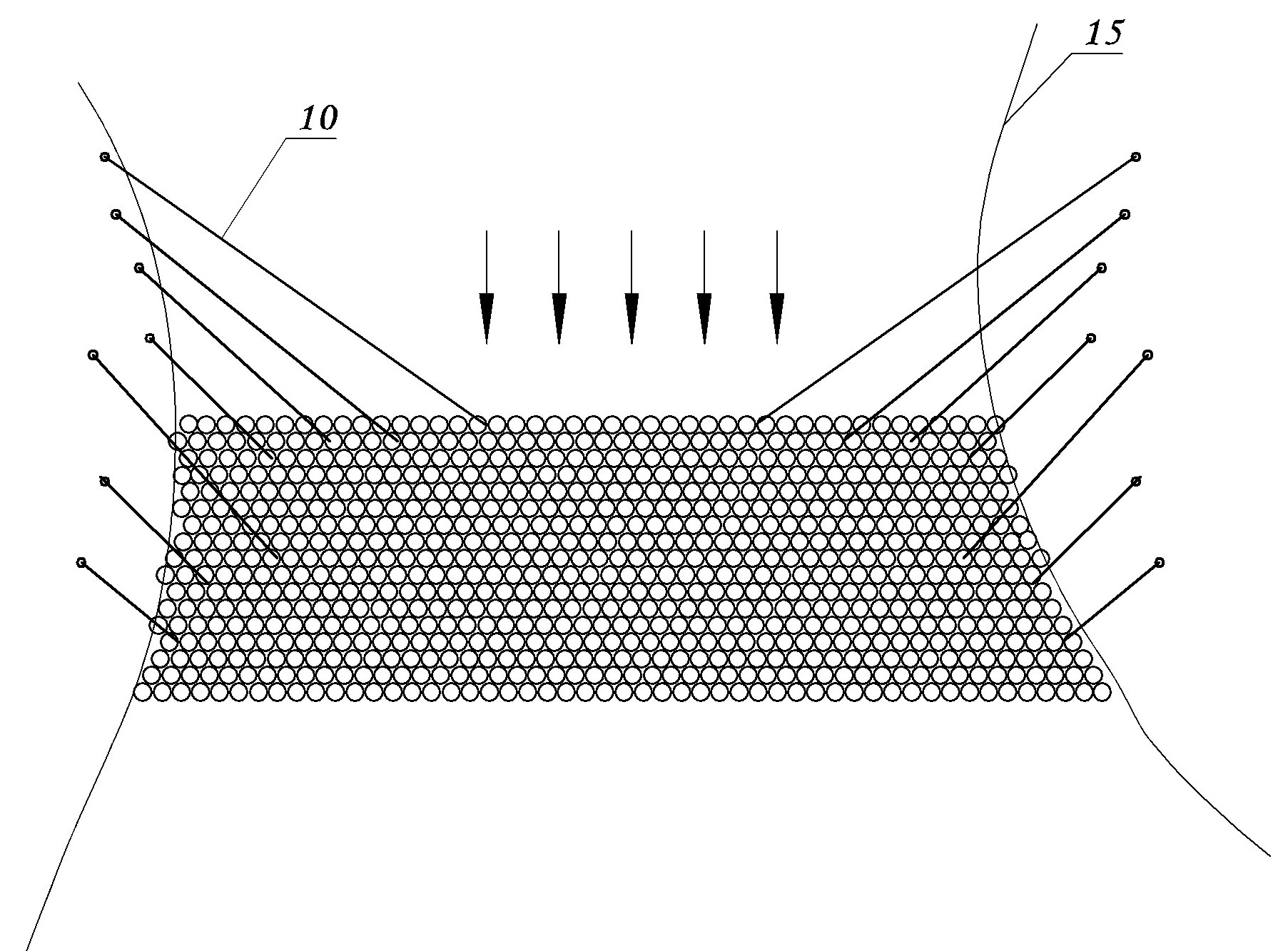

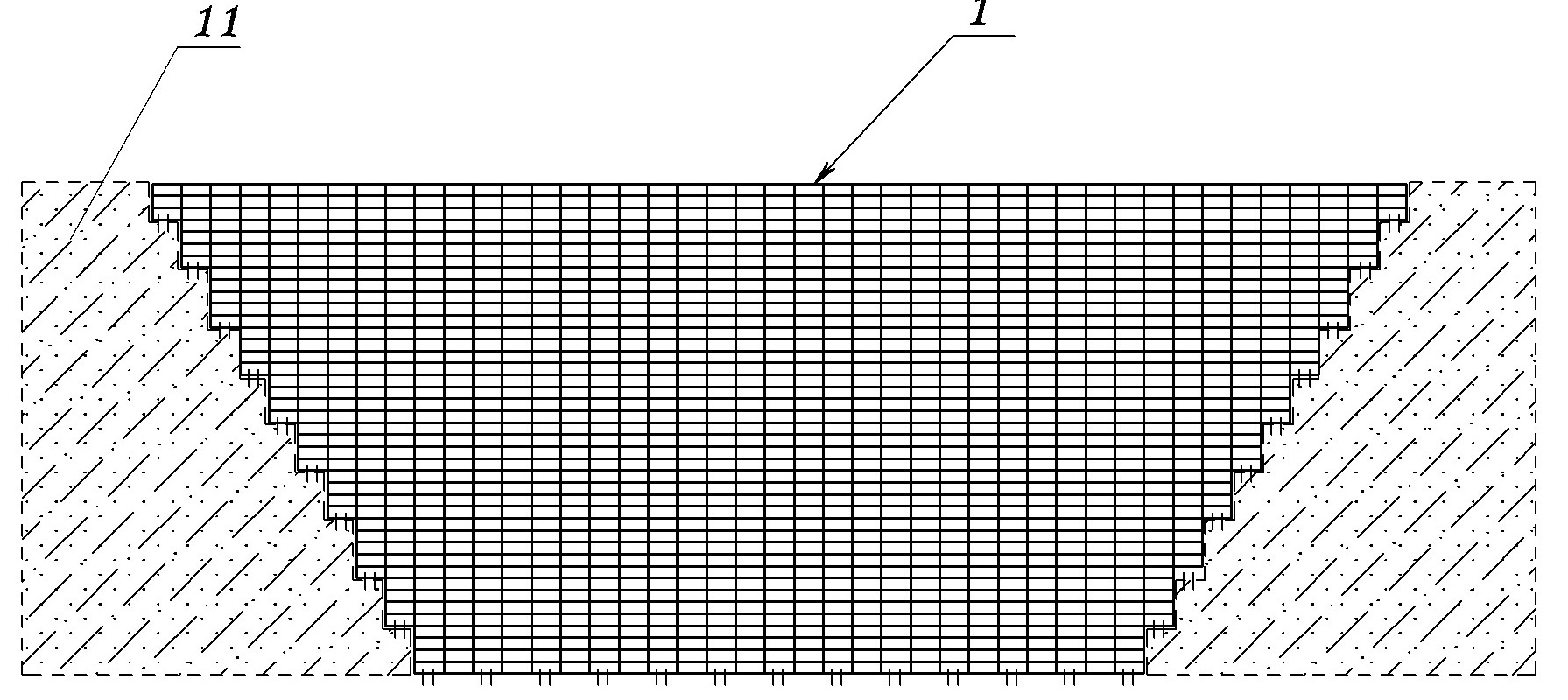

[0054] Embodiment one: see figure 1 , Figure 4 and Figure 5 , the dam body of the integral check dam is composed of multiple layers of the waste tire prestressed mesh vertically stacked. A group of waste tires on the same vertical line of the dam body penetrates vertically parallel steel strands vertically, and the two ends of the steel strands are respectively fixed on the outer surfaces of the upper and lower tires after prestressing; the inside of the dam body Nodes are set on the prestressed steel strands, and steel cables are distributed and fixed on each node. Each steel cable is pulled upstream along the countercurrent direction and fixed in the rock formation or on the slopes of the two banks.

[0055] Each layer of waste tire prestressed mesh is a network structure formed by sequentially butt jointing of a plurality of waste tire prestressed belts in the longitudinal direction, and longitudinally parallel steel strands 3 are inserted into the longitudinally adjace...

Embodiment 2

[0060] Embodiment 2: the accompanying drawings are not drawn, the content is basically the same as that of Embodiment 1, the similarities will not be repeated, the difference is: the two ends of the steel strand are respectively fixed with bolts, and the bolts cooperate with the nuts to fix the steel strand On the side spacers on the outer edge of the outermost tire.

Embodiment 3

[0061] Embodiment three: the accompanying drawings are not drawn, and the content is basically the same as that of embodiment one, and the similarities will not be repeated. The difference is: the opposite sides of the waste tire prestressed mesh are provided with conjoined gaskets, that is The ends of each steel strand are fixed on the same conjoined spacer, and the through hole at the intersection of the steel strand and the conjoined spacer is a bar-shaped hole, so as to facilitate the adjustment of the prestress of the steel strand in different directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com