Method for controlling extreme broken roof in roadway head

A control method and extremely crushing technology, used in tunnels, earth-moving drilling, temporary shielding, etc., to achieve the effect of improving strength and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

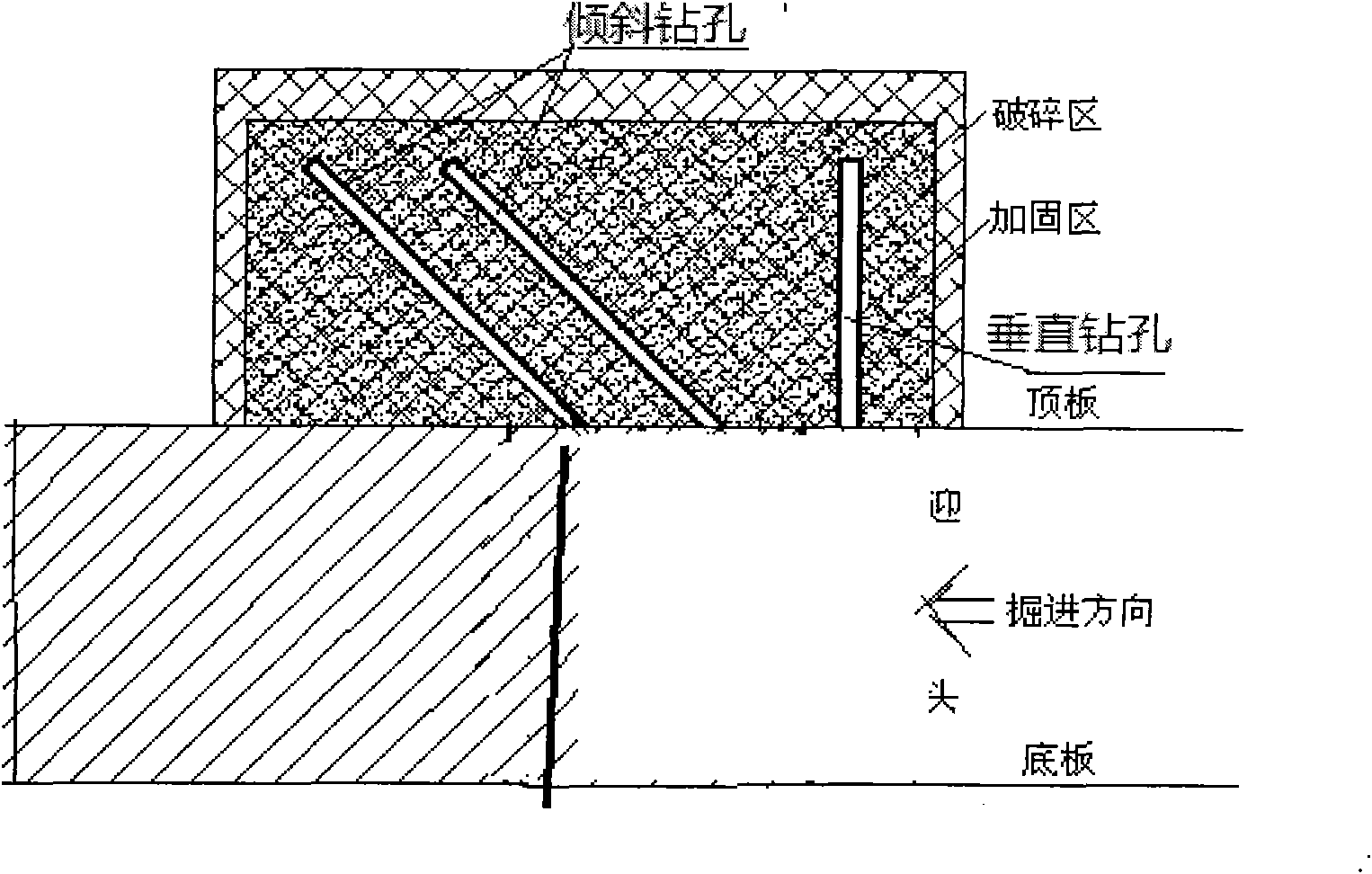

[0018] Such as Figure 1-3 As shown, the specific steps of the roadway head-on pole broken roof control method of the present invention are:

[0019] Step 1: Arranging the bolt support boreholes at the head of the roadway excavation

[0020] During the excavation process of the roadway, when it is found that the roof cracks develop, the small area is broken, the support body is abnormal, and the damage range extends to the deep part of the roadway (such as figure 1 As shown), 3-4 rows of drill holes are arranged on the roof of the roadway excavation, the drill hole spacing is 0.8m, the drill hole row spacing is 0.8-1.0m, and the drill hole depth is 3.0-5.0m; the direction of the outermost row of drill holes is perpendicular to On the rock face, the remaining rows of drilling holes are drilled obliquely upward at an angle of 60-75 degrees;

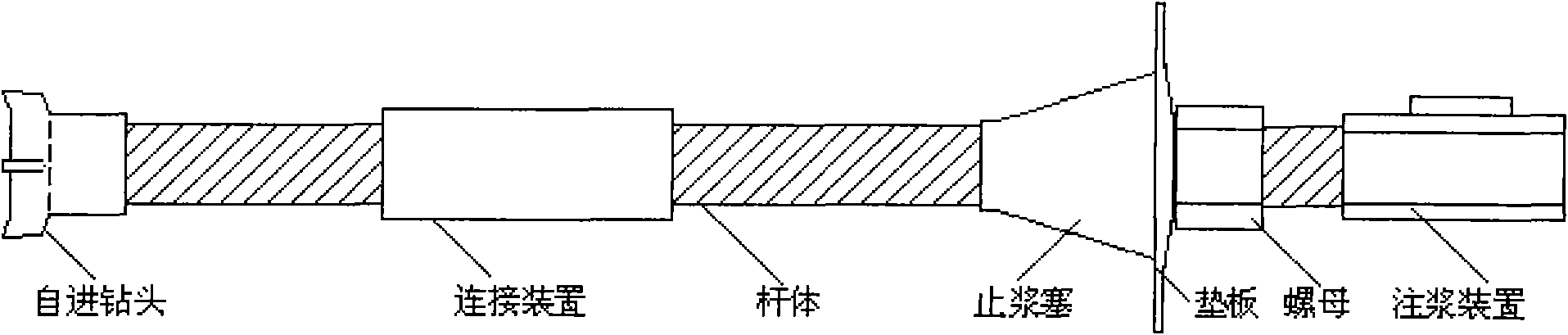

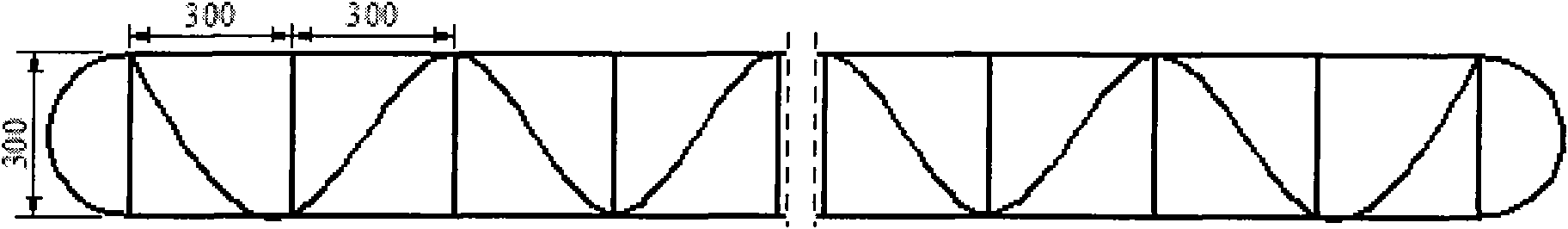

[0021] Step 2: Install self-drilling ordinary anchor rods with temporary roof protection with steel bars

[0022] Install self-drilling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com