Rapid maintaining method for broken roof in stope

A broken roof and rapid maintenance technology, applied in drilling equipment and methods, mining equipment, earthwork drilling and mining, etc., can solve the problems of insufficient effect and untimely prevention, and achieve the effect of preventing expansion and improving the strength of rock formations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The inventive method step is as follows:

[0019] Step 1: Design and maintain the anchor drilling for the broken roof of the stope

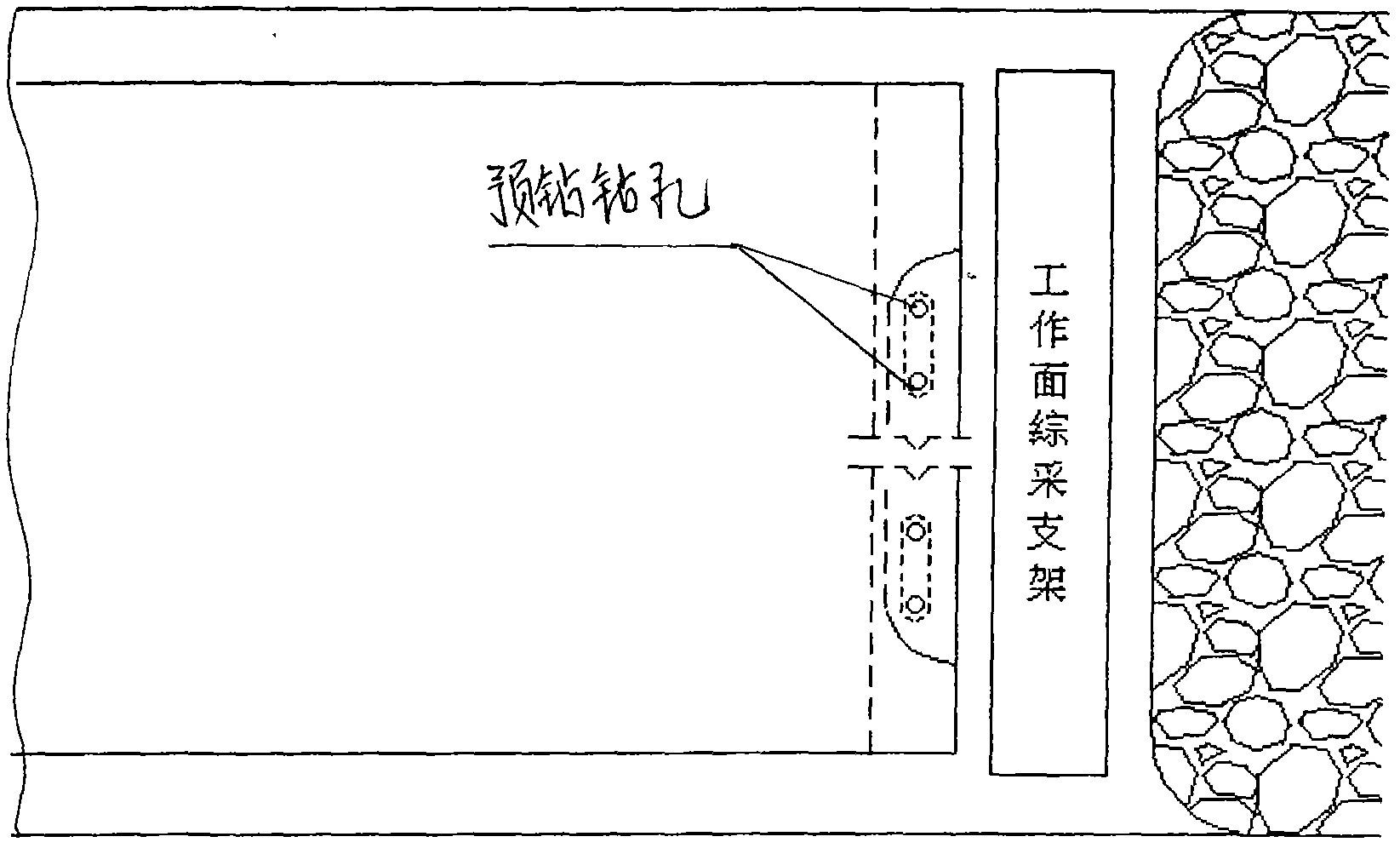

[0020] During the mining process of the working face, when there are areas where roof cracks develop, small-scale fractures, and pressure expansion tend to be obvious, two drill holes are arranged within every 1.4m, the drill hole spacing is controlled at 0.9-1.0m, and the pre-drilling depth is 1.0-3.mm. Such as figure 1 shown.

[0021] Step 2: self-drilling anchor rod with steel bar roof protection

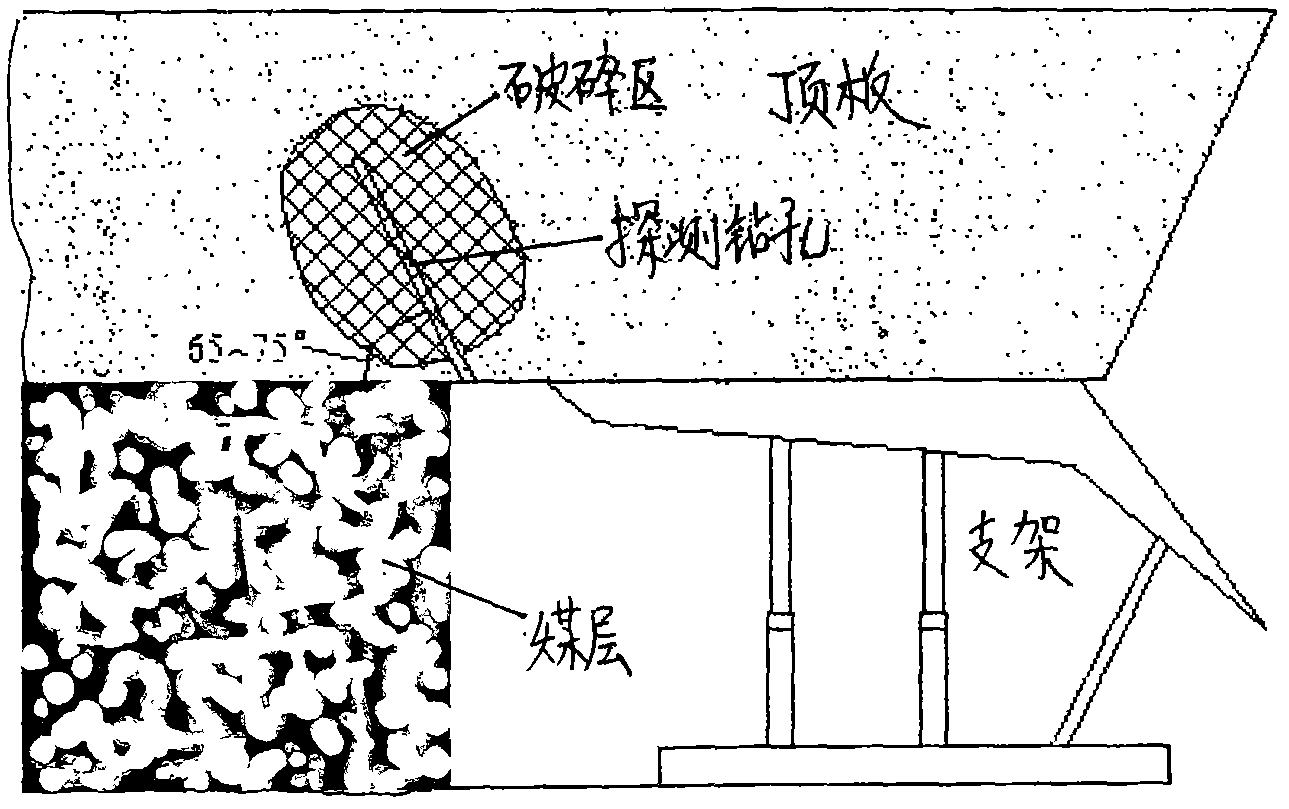

[0022] First, use common anchor drilling tools to detect the depth of the bolt on the pre-drilled hole. When the drilling tool reaches a certain depth and it is difficult to drill, it means that the drill hole has entered the complete rock formation, which is the effective depth. See figure 2 .

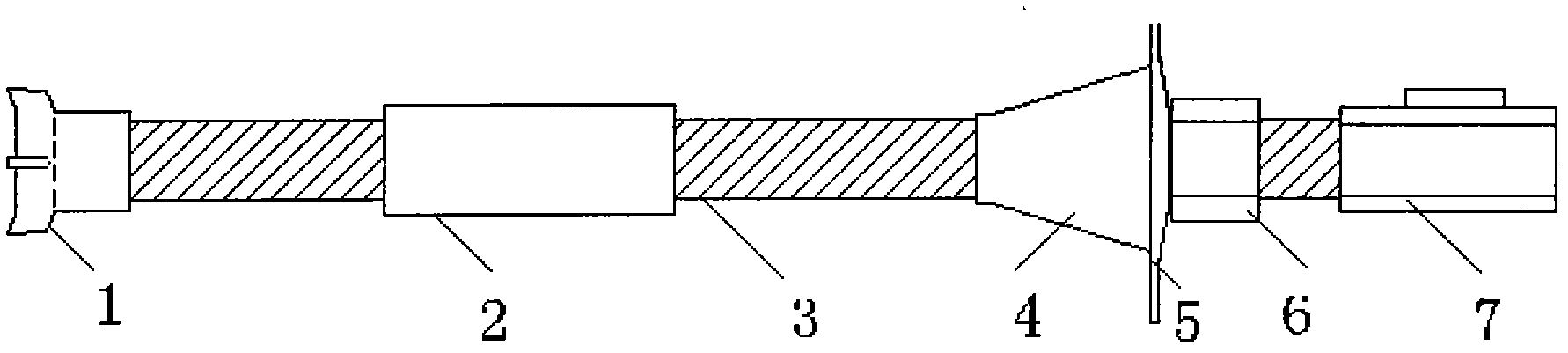

[0023] When the span of the broken roof is less than 100 meters and the depth is less than 15 meters, choose a self-drilling anchor with a len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com