One set of auxiliary overturning device for turbine base frame plate hoisting

A technology of turning device and steam turbine, which is applied to the details of milling machine equipment, metal processing, metal processing equipment, etc. It can solve the problems of reducing the work efficiency of the staff, failing to ensure the safety of the operator, and the danger of the operator, etc., to achieve simple structure and convenience The effect of turning over and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

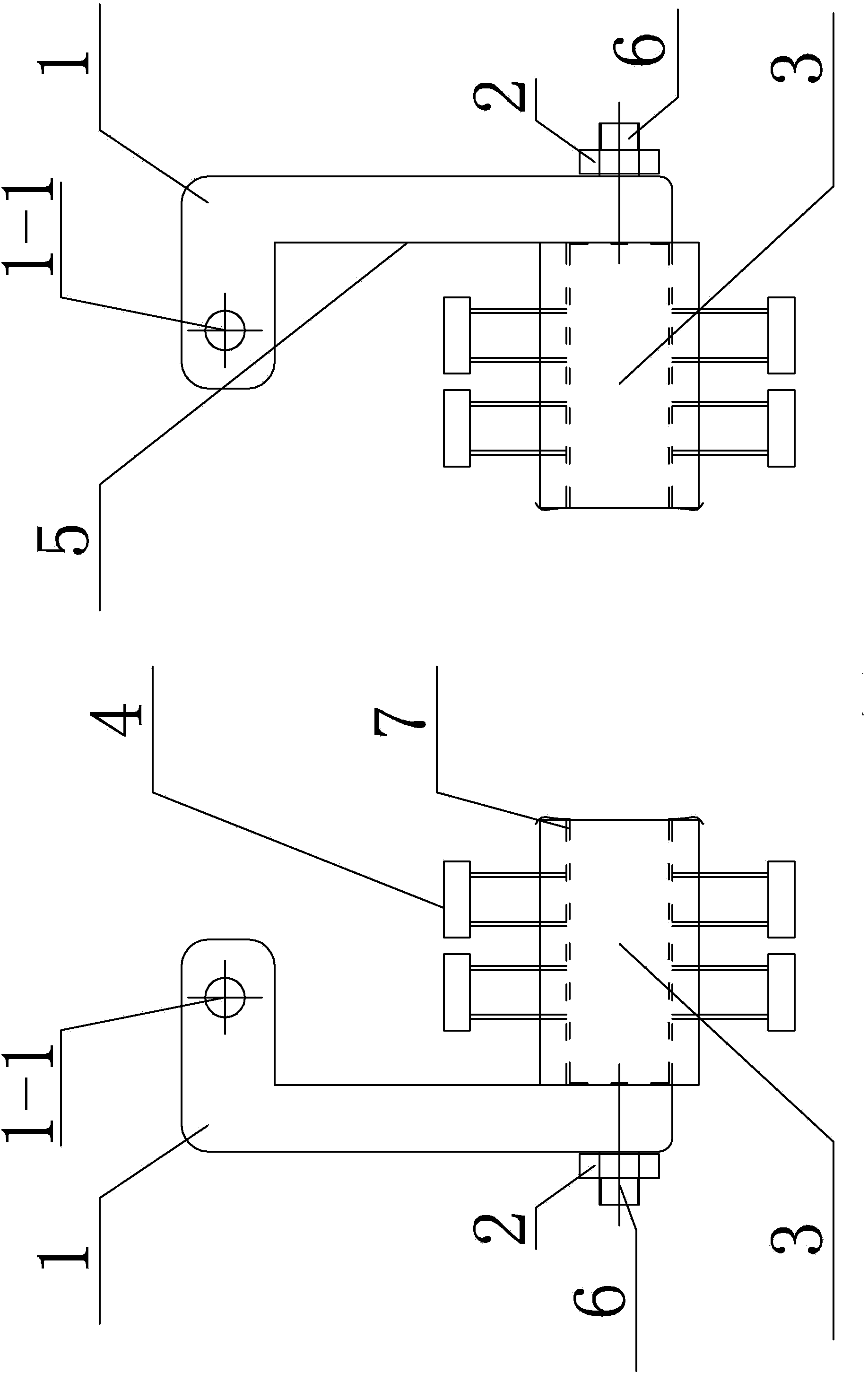

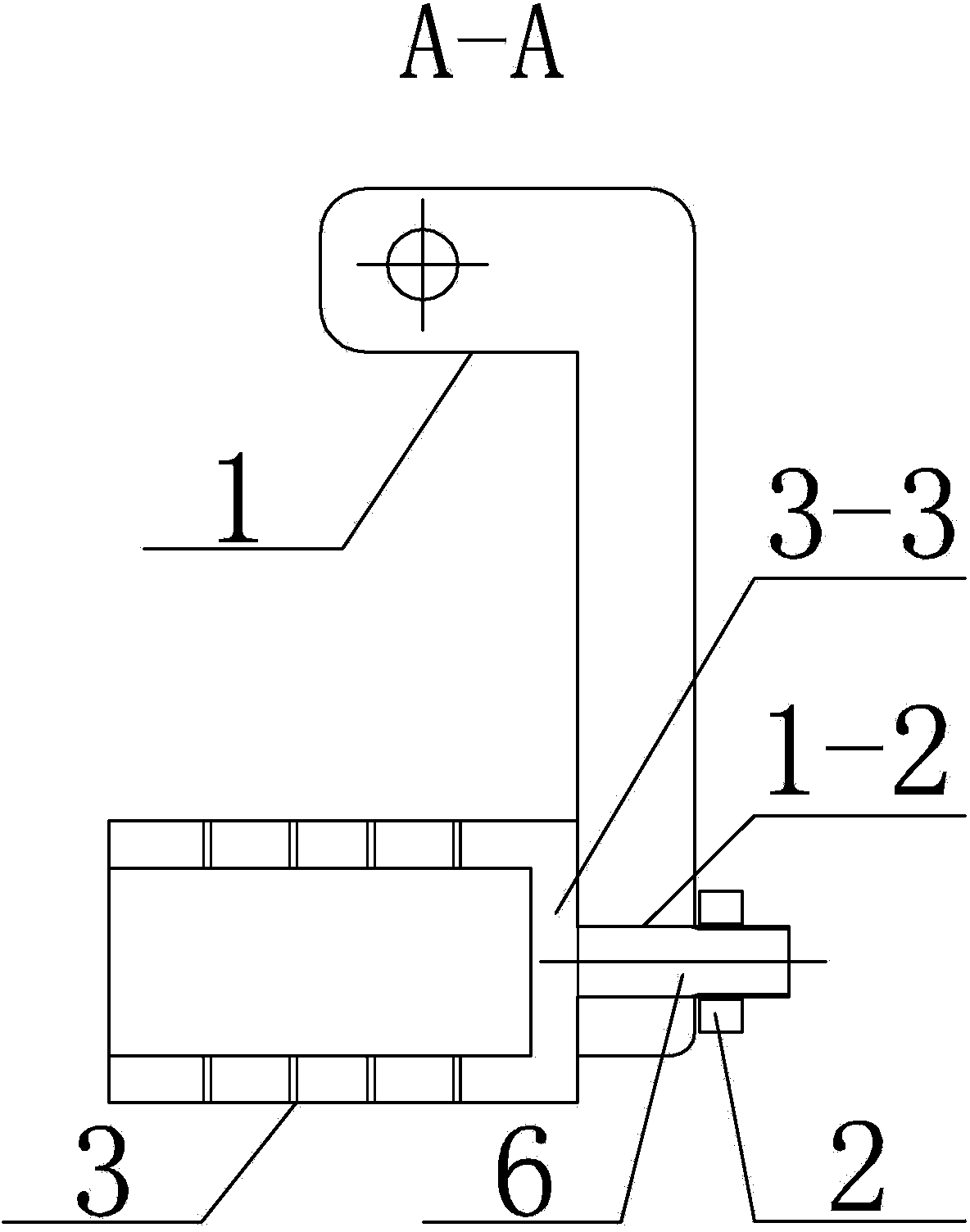

[0007] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment. The set of auxiliary turning devices used in the hoisting of the steam turbine base plate in this embodiment includes two turning mechanisms 5, and the turning mechanism 5 includes an 'L'-shaped tension block 1, a fixed locking Nut 2, reversing frame 3, cylinder 6 and a plurality of top tightening parts 4, reversing frame 3 is a box body with a hole at one end, and one end of cylinder 6 is fixedly installed on the outer wall of the opposite side plate of the opening end of reversing frame 3, The other end of the cylinder 6 is processed with an external thread, one end of the 'L'-shaped tension block 1 is processed with a first through hole 1-1, and the other end of the 'L'-shaped tension block 1 is processed with a second through-hole 1-1. 2, and the center line of the first through hole 1-1 is perpendicular to the center line of the second through hole 1-2, the external thread end of...

specific Embodiment approach 2

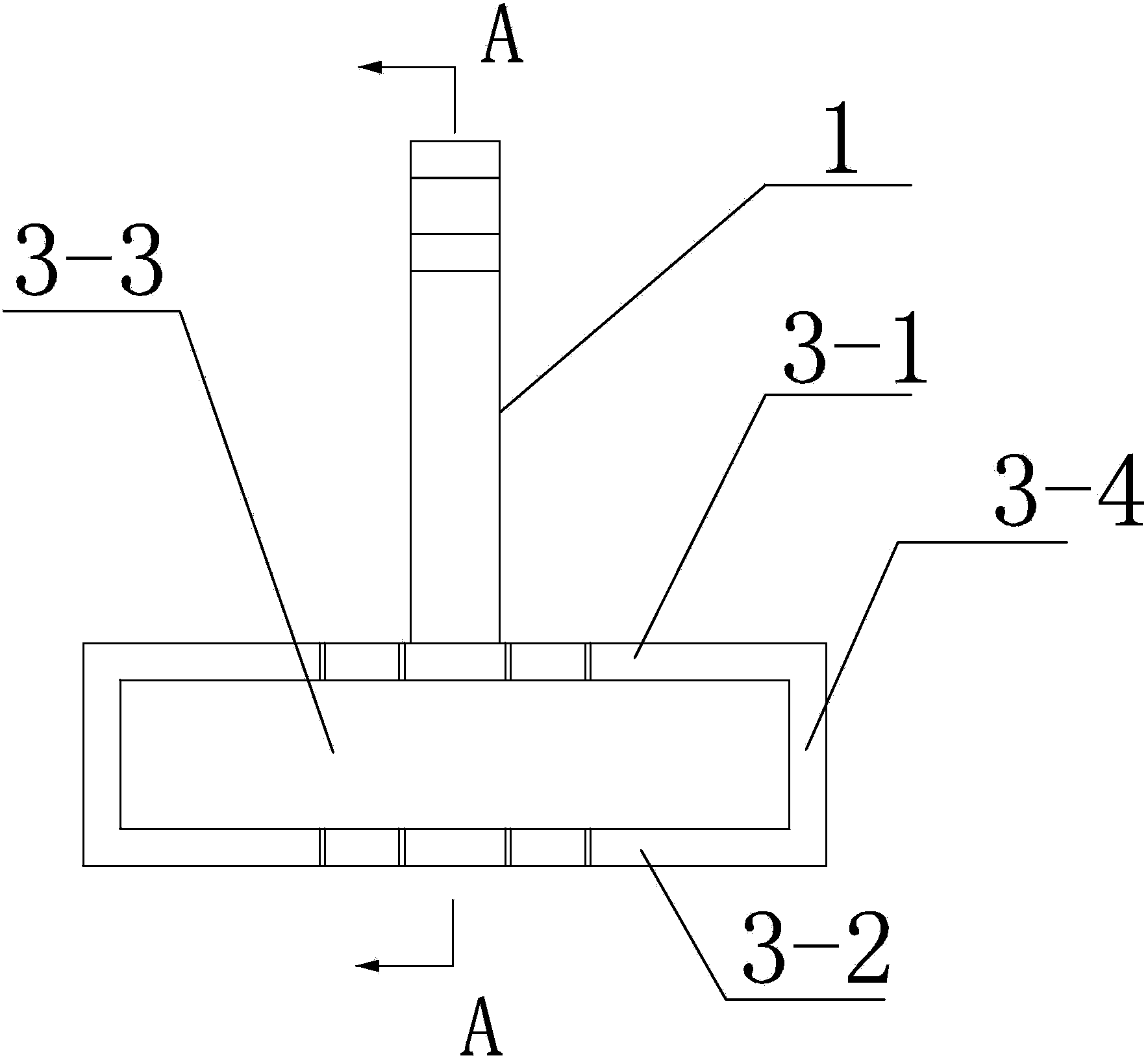

[0008] Specific implementation mode two: combination figure 1 with image 3 Describe this embodiment, a set of auxiliary turning devices for hoisting the base frame of a steam turbine described in this embodiment, the turning frame 3 includes an upper plate 3-1, a lower plate 3-2, a cylindrical fixing plate 3-3 and two A side plate 3-4, two side plates 3-4 are arranged oppositely, the upper plate 3-1 is fixedly installed on the top of the two side plates 3-4, and the lower plate 3-2 is fixedly installed on the two side plates 3-4 The bottom end of the cylindrical fixed plate 3-3 is fixedly installed on the two side plates 3-4, and the others are the same as the specific embodiment one.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 with figure 2 Describe the present embodiment. The set of auxiliary turning devices used in the hoisting of the steam turbine base plate in this embodiment, the turning device also includes two rubber sleeves 7, and each rubber cover 7 is laid on the inner wall of a turning frame 3 Above, others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com