Refrigerator cover plate and refrigerator storage chamber using same

A storage room and cover plate technology is applied in the field of refrigerator storage room components and refrigerator cover plates. Effects of stability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

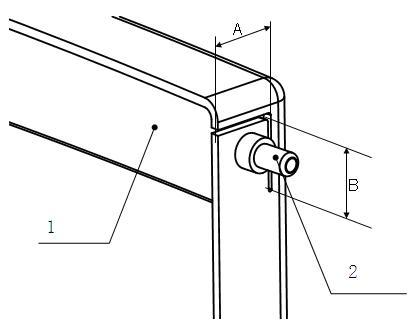

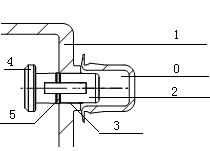

[0021] Such as figure 2 As shown, the refrigerator cover includes a cover body 1 and a rotating shaft 2 arranged on both sides of the cover body 1, wherein the rotating shaft 2 shown in the figure is connected to the cover body 1 in an assembled manner; One side of the cover plate body 1 assembled by the rotating shaft 2 is provided with a positioning hole 3, and the positioning hole 3 is in clearance fit with the rotating shaft 2; The moving part 4 is fixed with a snap ring I5 on the shaft body, and the distance between the snap ring I5 and the stop part 4 is equal to the wall thickness of the cover body 1 .

[0022] Among them, in order to ensure both the elastic margin during assembly and the supporting force of the rotating shaft after assembly, in this embodiment, the snap ring I5 is preferably a protrusion formed from the surface of the rotating shaft 2, and the shaft portion of the rotating shaft is axially There are long strip-shaped through holes, such as figure 2...

Embodiment 2

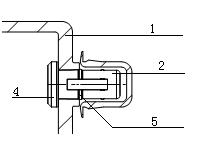

[0028] Such as Figure 4 As shown, a snap ring II6 is added on the rotating shaft 2 of the refrigerator cover, and the distance between the snap ring II6 and the snap ring I5 is set to the thickness of the cover body. When the rotating shaft 2 is not installed, due to the action of the snap ring II6 and the snap ring I5, the rotating shaft 2 is fixed on the side wall of the cover body 1 and is not easy to fall off.

[0029] During installation, the operator of the assembly line does not need to find the position between the rotating shaft 2 and the positioning hole 3, but can directly tap the end of the stop part 4 of the rotating shaft 2, so as to install the rotating shaft 2 into the groove 0 of the storage room , the status after installation is as follows Figure 5 As shown, it not only ensures the safety of the rotating shaft 2 during transportation, is not easily damaged, but also improves production efficiency.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap