Arc blowing device for low-voltage circuit breaker

A technology for low-voltage circuit breakers and arc extinguishing grids, which is applied to parts and components of circuit breakers, can solve the problems of increasing the degree of burning of lower contacts caused by arcs, and the inability to effectively change conductive components, etc., so as to reduce burning and Effect of small dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

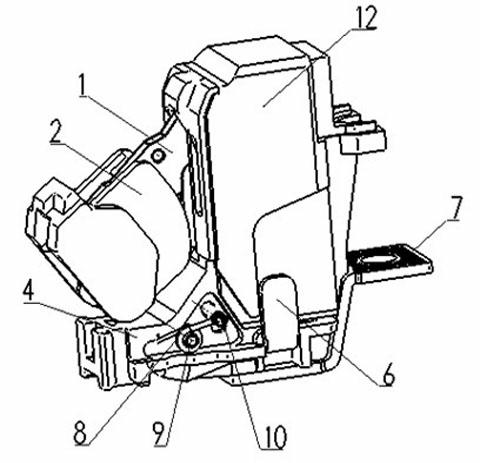

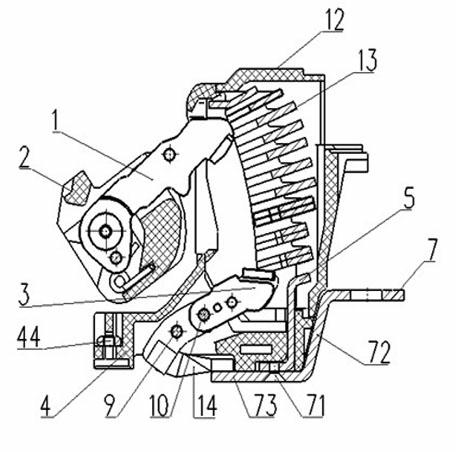

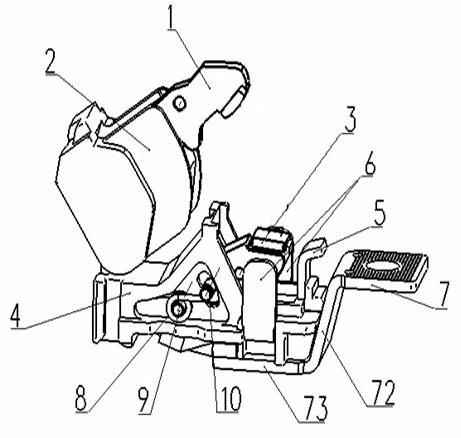

[0016] like Figure 1-3 As shown, the present invention includes an arc extinguishing chamber 12 , a moving contact 1 and a static contact 3 , the lower part of the arc extinguishing chamber 12 is a support 4 , and an arc extinguishing grid 13 is arranged in the inner cavity of the arc extinguishing chamber 12 . The front end of the moving contact 1 is a rotating end, the rotating end is connected to the rotating shaft 2, and is located outside the arc extinguishing chamber 12, the rear end of the moving contact 1 is a contact end, and the contact end extends into the inner cavity of the arc extinguishing chamber 12; The front end of the contact 3 is the connection end, which is pivotally connected to the bracket 4, and the rear end of the static contact 3 is the contact end, which extends into the inner cavity of the arc extinguishing chamber 12 and is located on the arc extinguishing grid. The lower part of sheet 13 corresponds to the contact end of moving contact 1.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com