Free wheel, especially for a crank CVT

一种自由、夹紧体的技术,应用在离合器、单向离合器、机械设备等方向,能够解决妨碍夹紧功能等问题,达到改善缓冲功能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

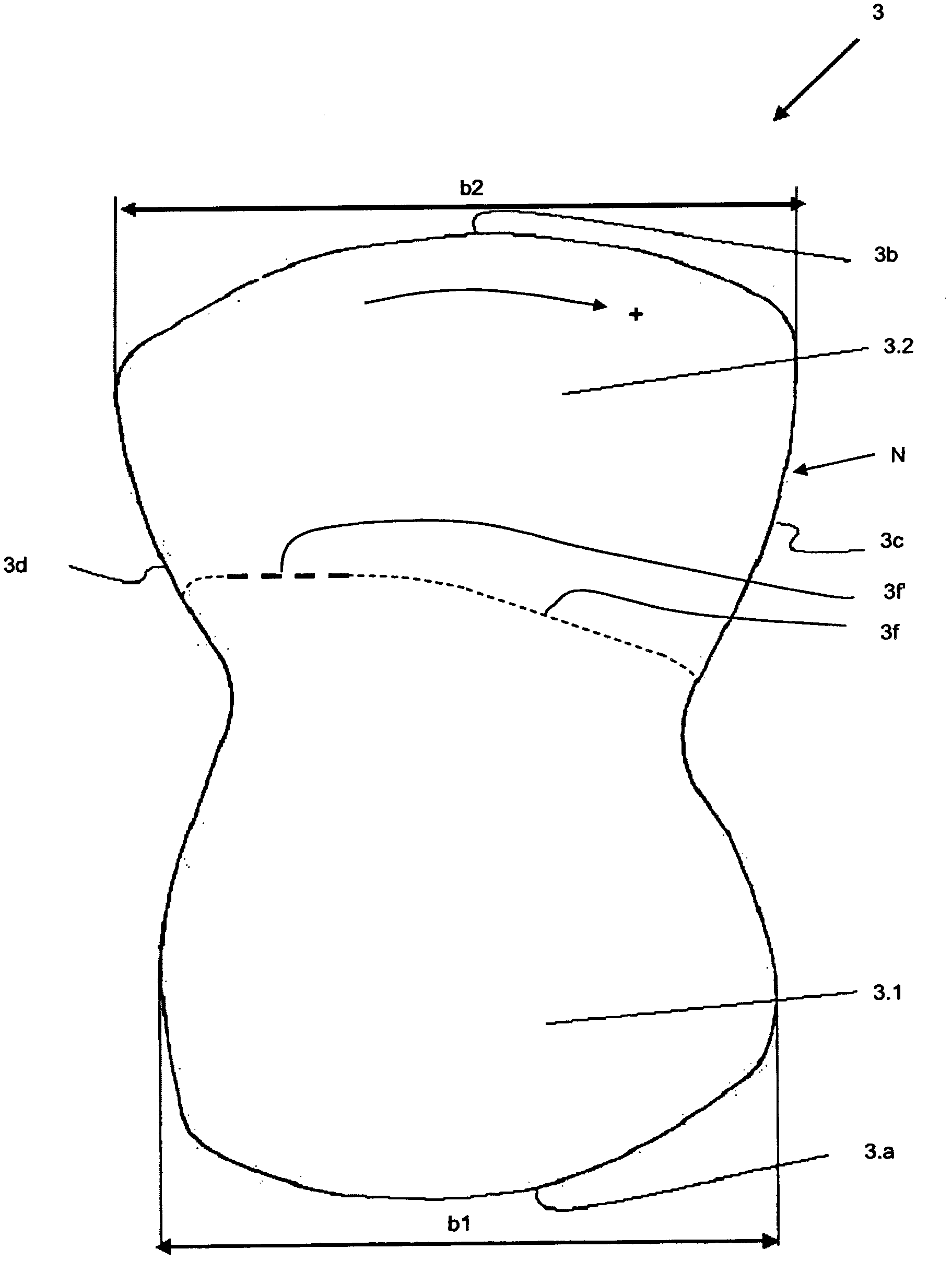

[0023] figure 1 Shows a front view of the clamping body 3 with a base region 3.1 and a head region 3.2, wherein the base region 3.1 has a contact surface 3a in the direction of the inner ring, not shown here, and the head region 3.2 faces the freewheel In the direction of the outer ring, not shown here, there is a contact surface 3b.

[0024] The base region 3 . 1 has a width b1 , the head region has a larger width b2 than this. A constriction, not shown in detail, is formed between them.

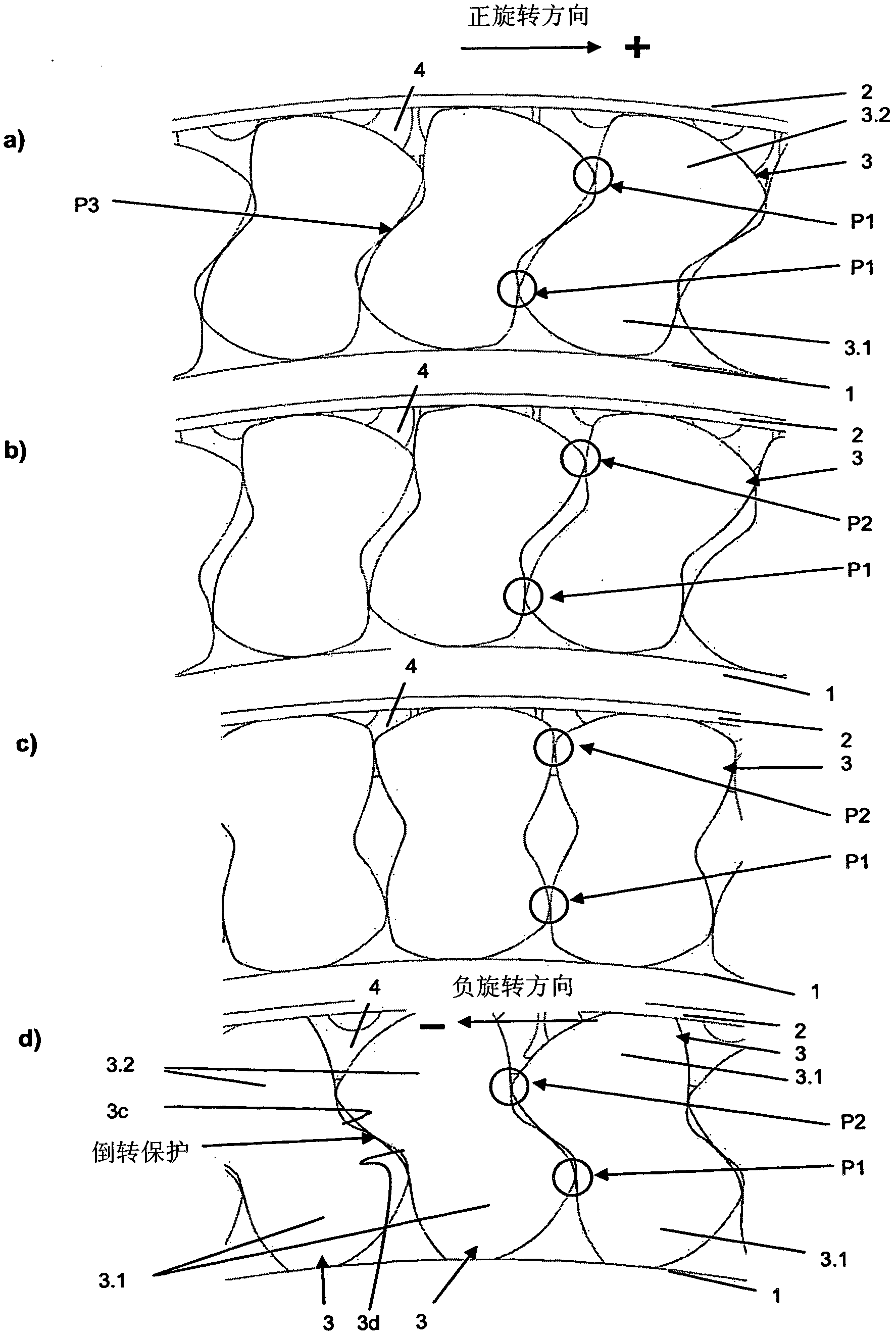

[0025] In the pivoting direction of the clamping body 3 indicated by the arrow, a first abutment surface 3c and, conversely, a second abutment surface 3d are formed during shock loading (positive direction of rotation+), which point to the not shown Out of the adjacent clamping body.

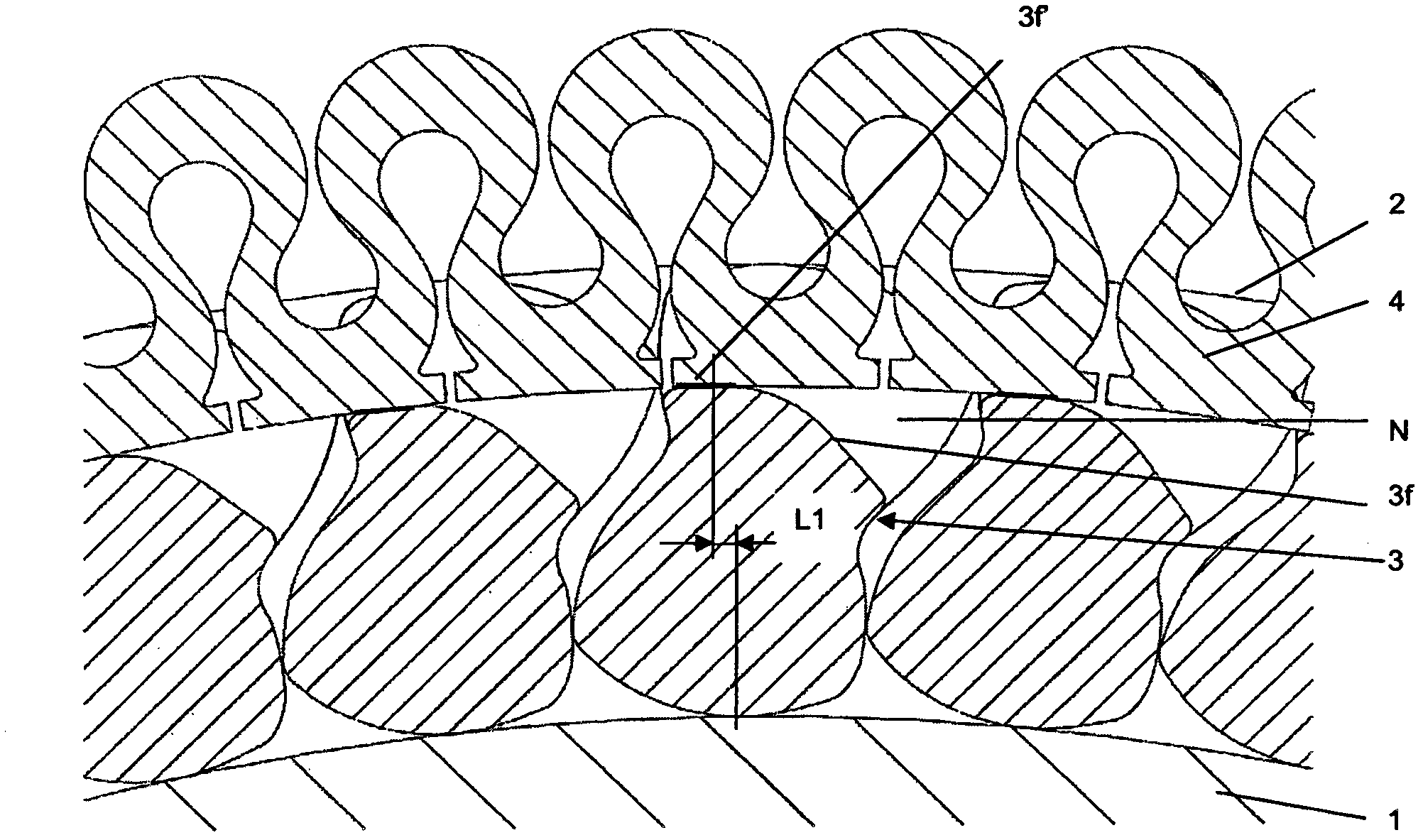

[0026] The clamping body 3 also has a buffer groove N open towards the outer ring (see image 3 with 4 ), which has a pressure surface 3f indicated here by a dotted line, on which a spring not shown, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com