Method for preparing soy sauce for enhancing flavor

A soy sauce and flavor technology, applied in the field of fermentation engineering, can solve the problems of increasing enterprise technology and cost, single beneficial microorganisms, insufficient flavor substances in brewing soy sauce, etc., and achieve good taste and aroma and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

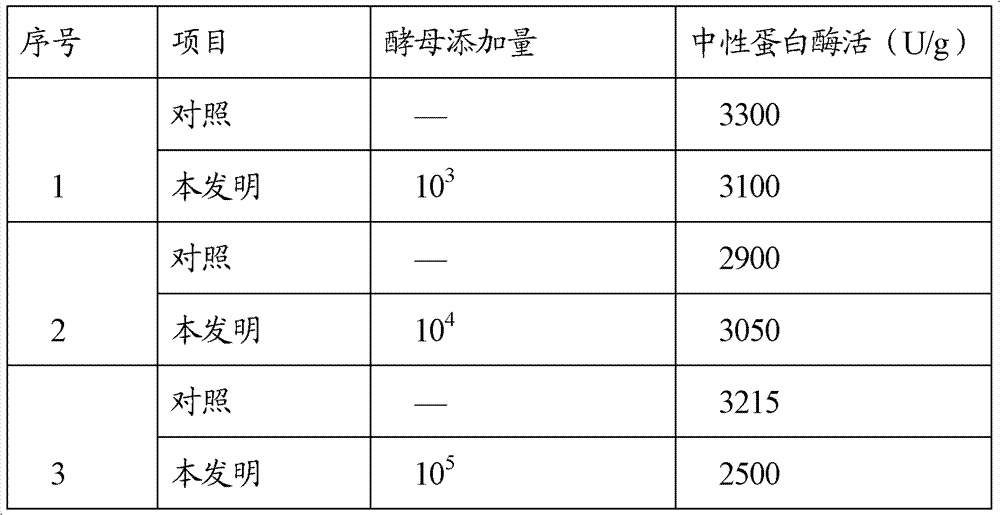

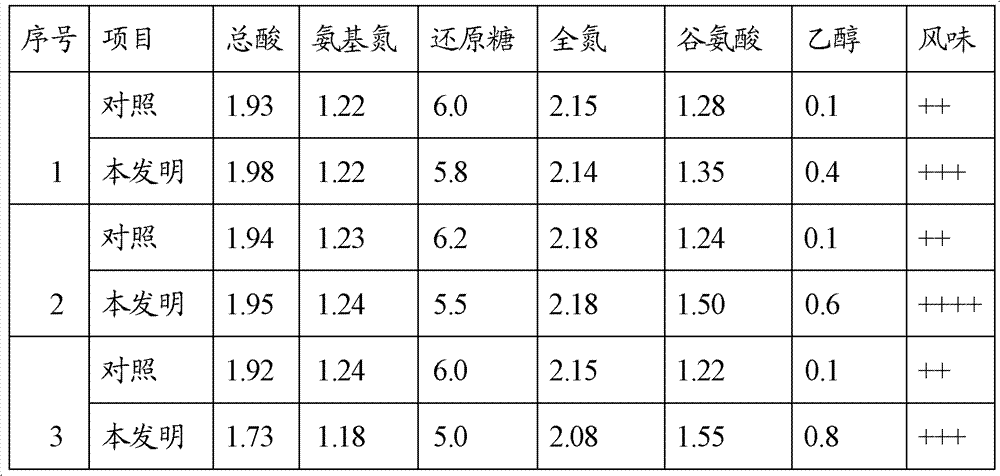

Embodiment 1

[0024] Saccharomyces cerevisiae was activated and cultured on a slant surface and expanded to maturity to obtain a yeast culture solution. The culture solution was centrifuged at a centrifugal speed of 5000r / min for 30 minutes to collect the bacteria, and the bacteria were mixed with flour 5 times its weight. The flour contained Glucose, the content of glucose in the flour will make the glucose weight percentage in the final koji material be 0.01‰, press 10 3 ~10 5 Yeast / g koji material, mixed with Aspergillus oryzae, conventional bran koji operation. Select the Aspergillus oryzae strain with a germination rate of 90%, and the total number of yeast in the yeast culture solution is ≥1.0×10 8 , the number of live yeasts accounts for more than 90%, the temperature in the early stage of koji making is controlled at 32°C, and the humidity is controlled at more than 90%. After 15 hours from the start of koji making, the koji is turned over. Stir once a day, stir three times in tot...

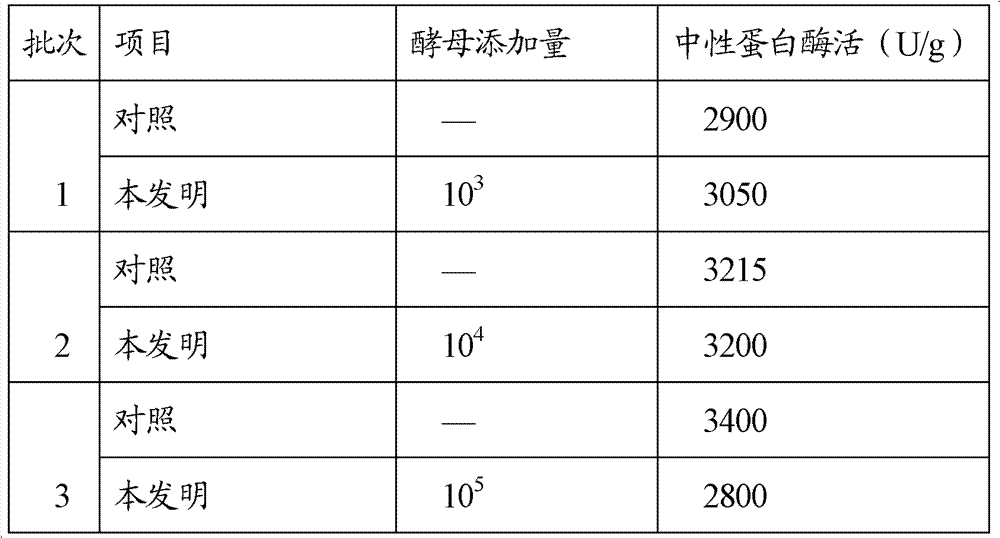

Embodiment 2

[0033] Zygomyces rouckeri slant activation culture and expansion to maturity, centrifuge the culture solution at a centrifugal speed of 3000r / min for 10min, collect the bacteria, mix the bacteria with 8 times its weight of flour, the flour contains glucose, flour The content of glucose in the medium will make the glucose weight percent composition in the final koji material be 0.05‰, then by 10 3 ~10 5 Yeast / g koji material, mixed with Aspergillus oryzae, conventional bran koji operation. Regular aeration during the fermentation process is conducive to the proliferation of yeast and alcoholic fermentation. Select the Aspergillus oryzae strain with a germination rate of 90%, and the total number of yeast in the yeast culture solution is ≥1.0×10 8 , the number of live yeast accounts for more than 90%, the temperature in the early stage of koji making is controlled at 34 ℃, the humidity is controlled at above 92%, the koji is turned over for 16 hours, after the koji making is f...

Embodiment 3

[0043] Saccharomyces cerevisiae and Zygomyces ruckeri were respectively activated and cultured and expanded to maturity. The culture medium was centrifuged at a centrifugal speed of 4000r / min for 20 minutes. After centrifugation, the bacteria were mixed with flour 10 times its weight. The flour contained glucose. The content of glucose in the flour should make the weight percentage of glucose in the final koji material be 0.05‰, and the addition amount of two kinds of yeasts, according to the test conclusions of embodiment 1 and embodiment 2, respectively use 2×10 3 and Saccharomyces cerevisiae / grams, 2×10 4 Mix a Zygomyces ruckeri / keji material with Aspergillus oryzae; the temperature in the early stage of koji making is controlled at 35°C, and a higher temperature is beneficial to the rapid growth of multiple strains, and the koji is turned for 14 hours, and then controlled at 30-35°C. The growth and metabolism of bacteria produce a large amount of heat and prevent high temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com