Rocking-rolling riveting machine

The technology of riveting machine and riveting head is applied in the field of non-slip pure pendulum roller riveting machine and pendulum roller riveting machine. The effect of good surface quality and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

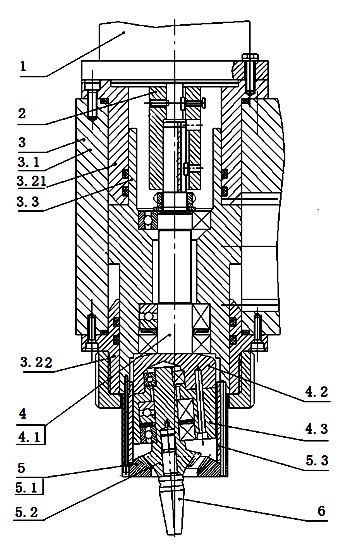

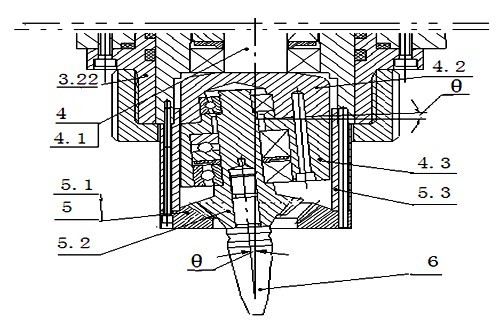

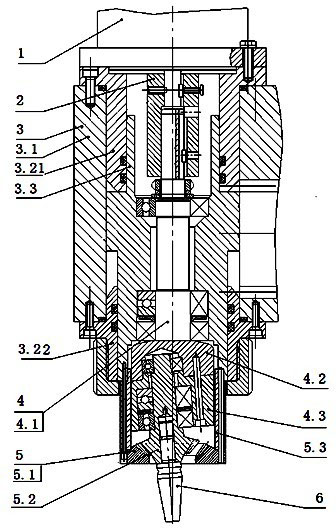

[0022] Example 1: The pendulum mill riveting machine has a motor 1, a coupling 2, a hydraulic cylinder system 3, a spindle system 4, a differential gear train 5 and a riveting head 6; the hydraulic system 3 includes a hydraulic cylinder housing 3.1 and has a shaft hole The piston 3.3, one end of the hydraulic cylinder housing 3.1 is fixed with a hydraulic cylinder upper inner sleeve 3.21, and the other end is fixed with a hydraulic cylinder lower inner sleeve 3.22; the main shaft 4.1 of the main shaft system 4 is installed in the shaft hole of the piston 3.3 through a bearing; One end of the main shaft 4.1 is connected with the transmission shaft of the motor 1 through a coupling 2, and the other end has a main shaft head seat 4.2; a moving gear seat 4.3 is fixed on the end surface of the main shaft head seat 4.2; the differential gear train 5 includes a fixed gear 5.1 and a moving gear Gear 5.2; the moving gear 5.2 is installed in the shaft hole of the moving gear seat 4.3 t...

Embodiment 2

[0023] Example 2: The difference from Example 1 is that the angle between the axis line of the riveting head 6 and the axis line of the main shaft 4.1 is equal to the plane where the main shaft head seat 4.2 and the movable gear seat 4.3 are combined and the plane of the main shaft 4.1. The angle between the vertical line of the axis line, the value of angle θ is 1 to 4 degrees.

Embodiment 3

[0024] Example 3: The difference from Example 1 is that the angle between the axis line of the riveting head 6 and the axis line of the main shaft 4.1 is equal to the plane where the main shaft head seat 4.2 and the movable gear seat 4.3 are combined and the plane of the main shaft 4.1. The angle between the vertical line of the axis line, the value of angle θ is 1 degree.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com