Closed type blind rivet

A blind rivet and closed technology, applied in rivets and other directions, can solve the problems of increasing warehouse inventory and inconvenient riveting processing, and achieve the effects of excellent hole filling performance, simple processing and manufacturing, and reduced inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

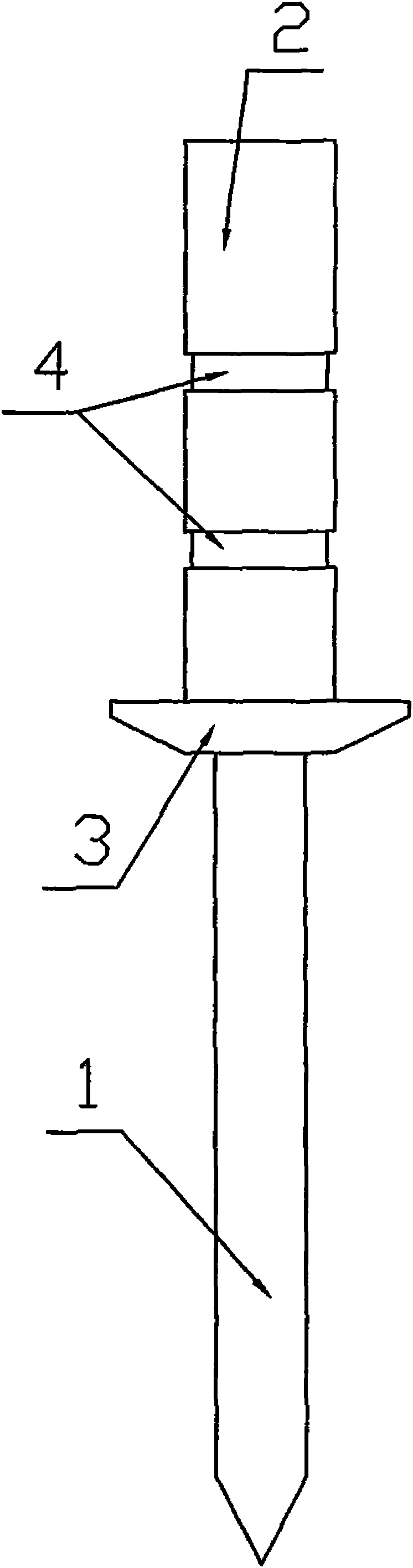

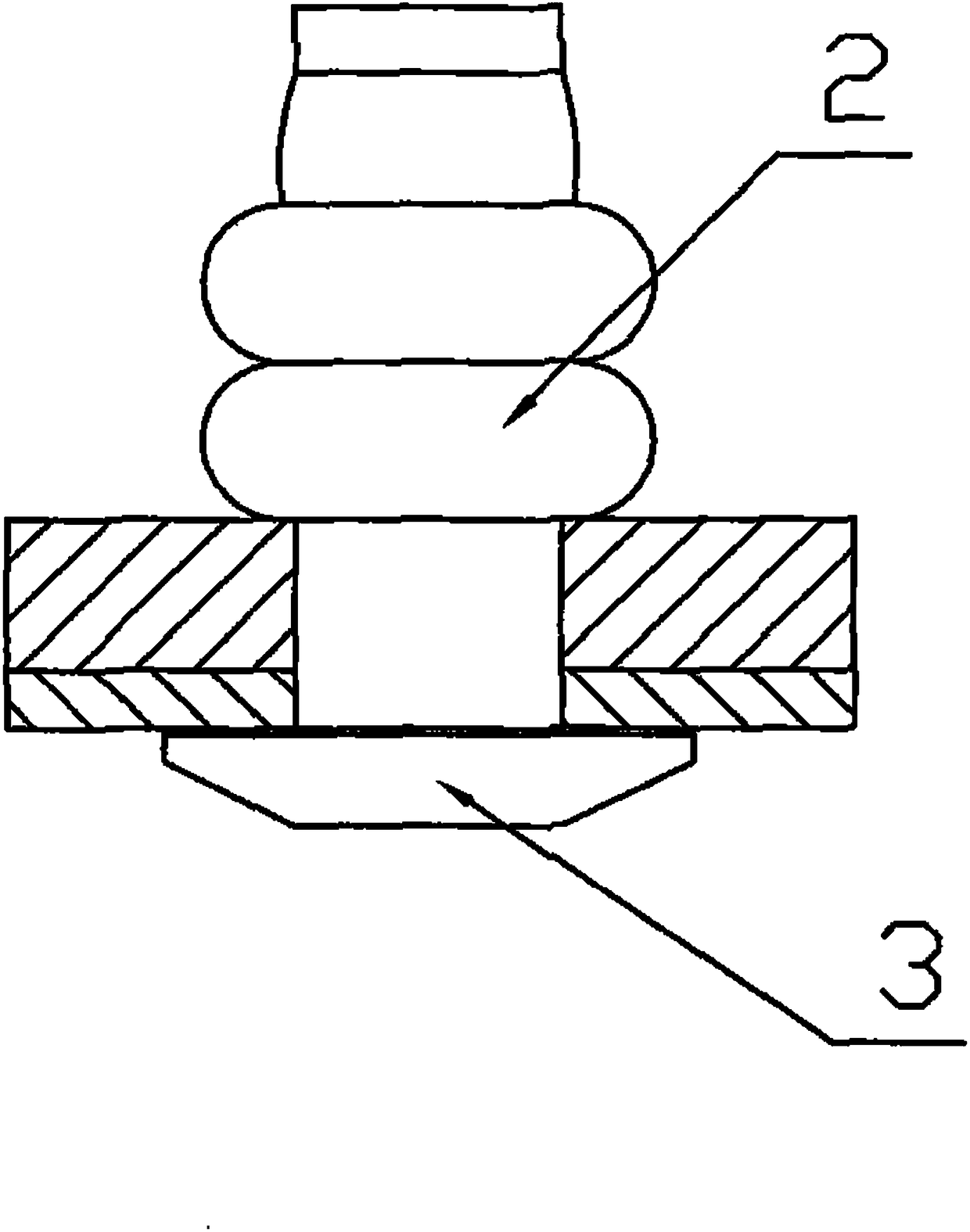

[0011] A closed blind rivet, comprising a mandrel rod 1 and a nail body 2, the nail body 2 is a tubular structure with a closed head, and a radially outer boss used as a nail cover 3 is provided in the circumferential direction of the tail. The head of mandrel 1 is fixed in the nail body 2, the afterbody of described nail mandrel 1 runs through described nail body 2 and stretches out outside described nail cover 3, the outer wall of described nail body 2 along Two annular grooves 4 are provided in the circumferential direction, the width of the annular grooves 4 is 2mm, and the distance between the two annular grooves is 4mm.

[0012] The nail body is inserted into the riveted hole from one side. When riveting, the mandrel rod is pulled by the special tool riveter, so that the end of the nail body 2 without the nail cover 3 is deforme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com