Kits for injection molding machines for molded parts

A technology for injection molding machines and molding parts, which is used in household components, applications, household appliances, etc., and can solve problems such as expensive machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

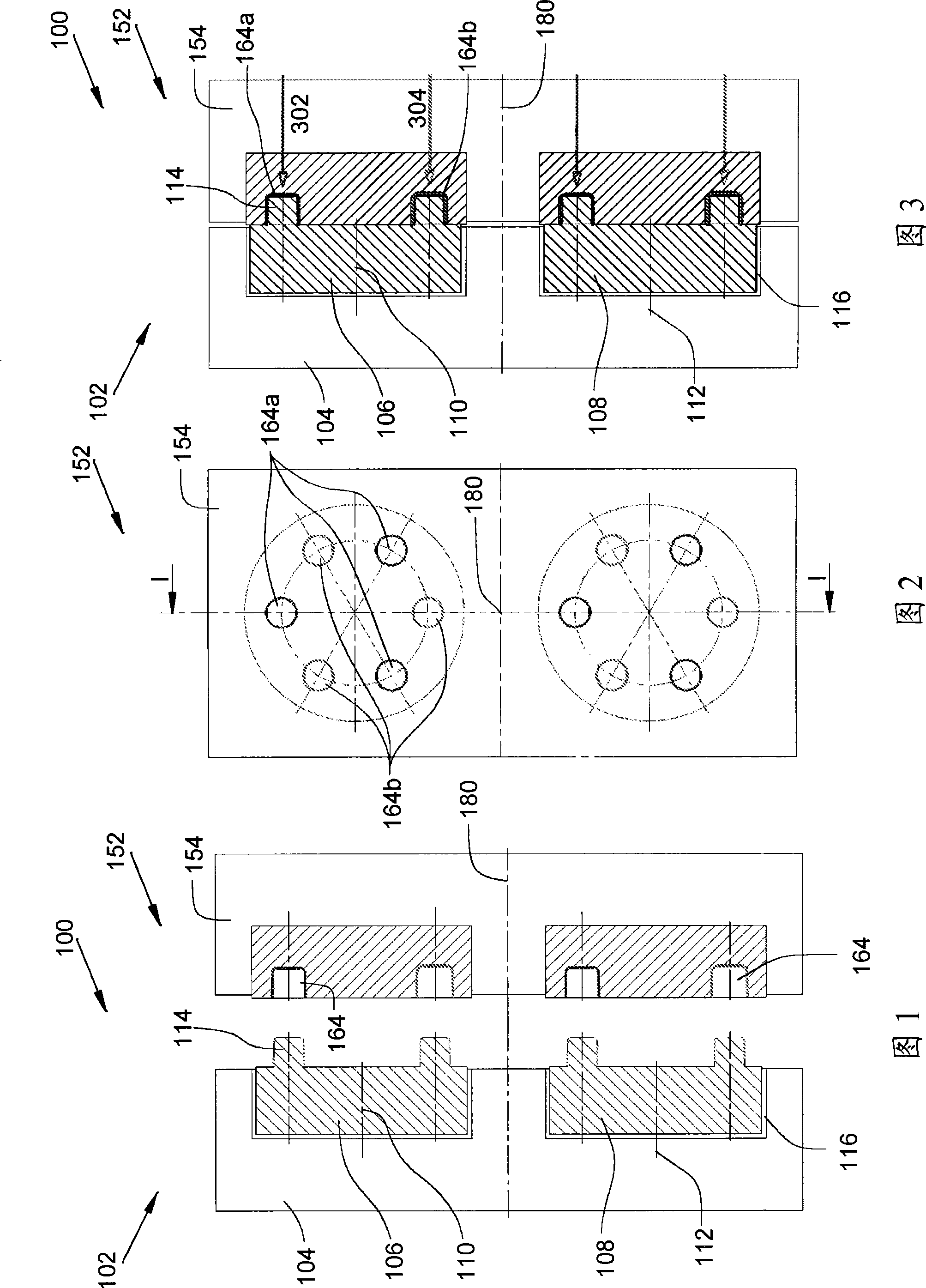

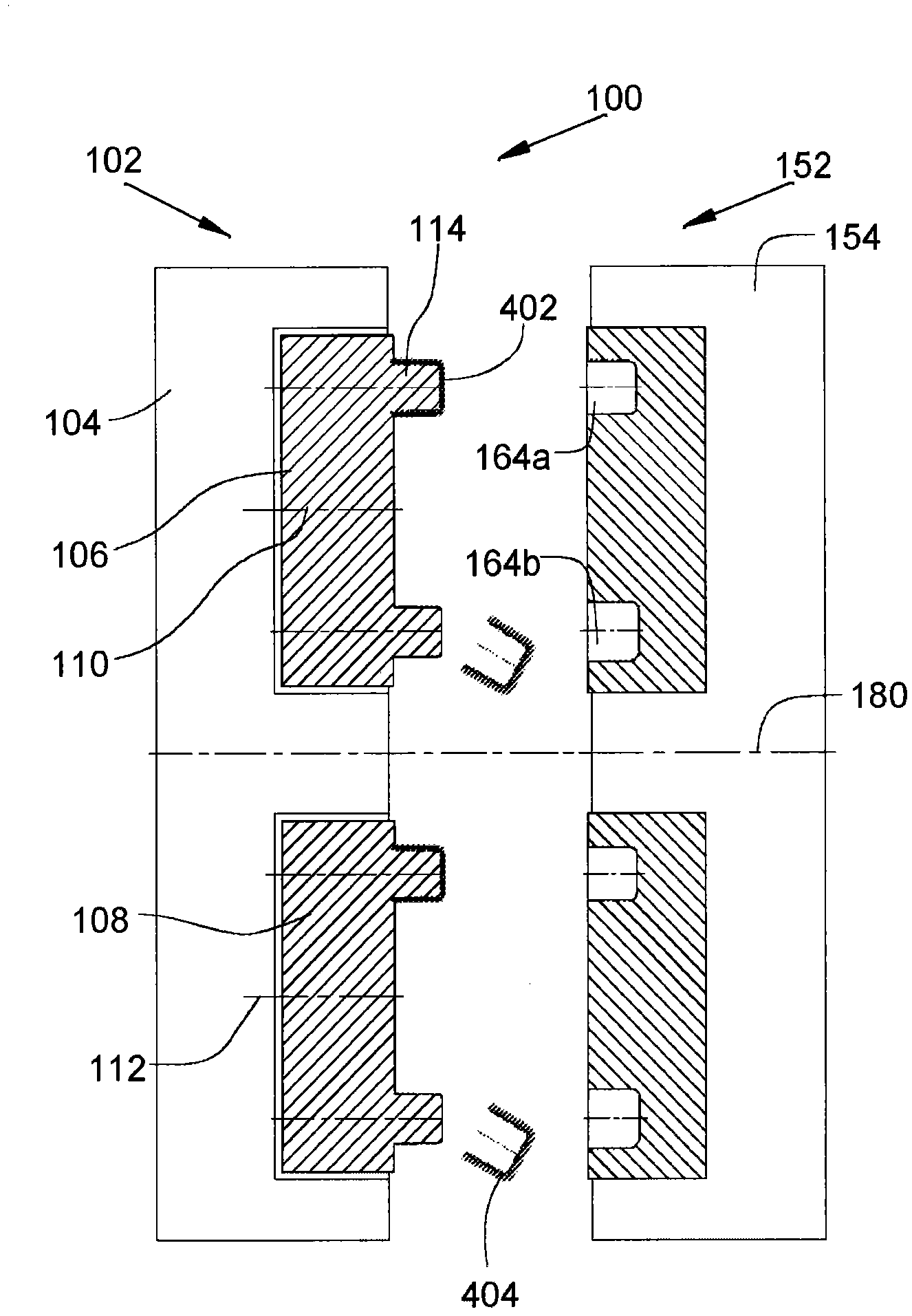

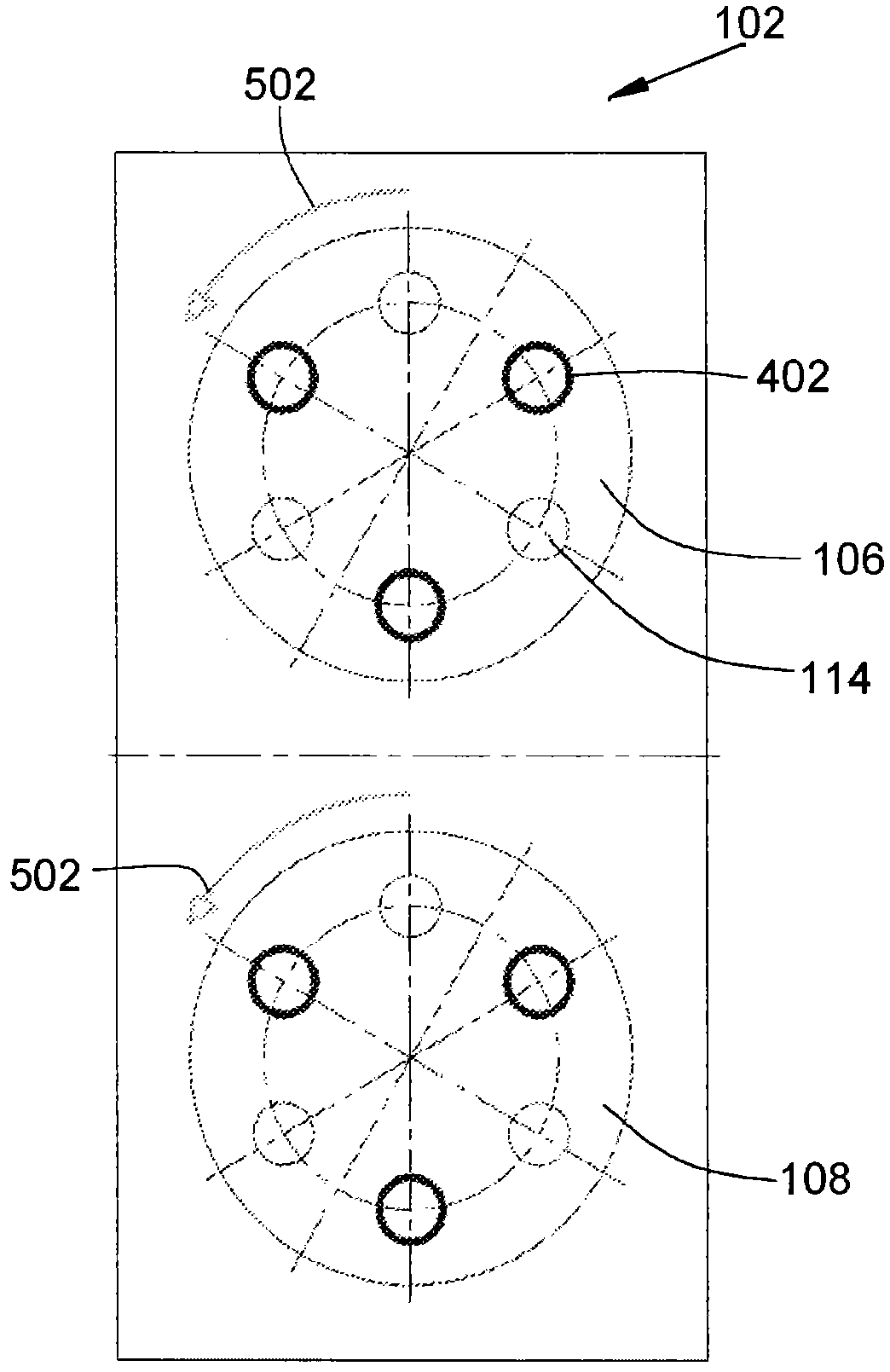

[0036] In the assembly in the figure, the kit is mounted on an injection molding machine connected to an injection press (not shown) which supplies the space defined by the cavity (empreinte) and the mating cavity (contre-empreinte). Molding material.

[0037] In the following description, the term "cavity" denotes a forming form provided on the cylindrical member, and the term "mating cavity" denotes an associated forming form complementary to said cavity. Accordingly, the molding cavities provided on the barrel may be referred to as "cavities" and "mating cavities". Forming cavities placed directly on the support plate are called "mating cavities".

[0038] The forming machine comprises a first platen and a second platen designed to be movable relative to each other by sliding in a translation direction 180 so as to be successively in an open state and a closed state.

[0039] figure 1 A kit 100 is shown for an injection molding machine for producing parts by molding and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com