Method for connecting a structural member made of a composite material to a tube

A technology of structural elements and composite materials, applied in the direction of household elements, connecting rods, tubular objects, etc., can solve the problems of heavy components, huge connections, and difficult manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention is described below as applied to the field of aviation, and in particular to the field of landing gear. Of course, the invention is not limited to this type of application.

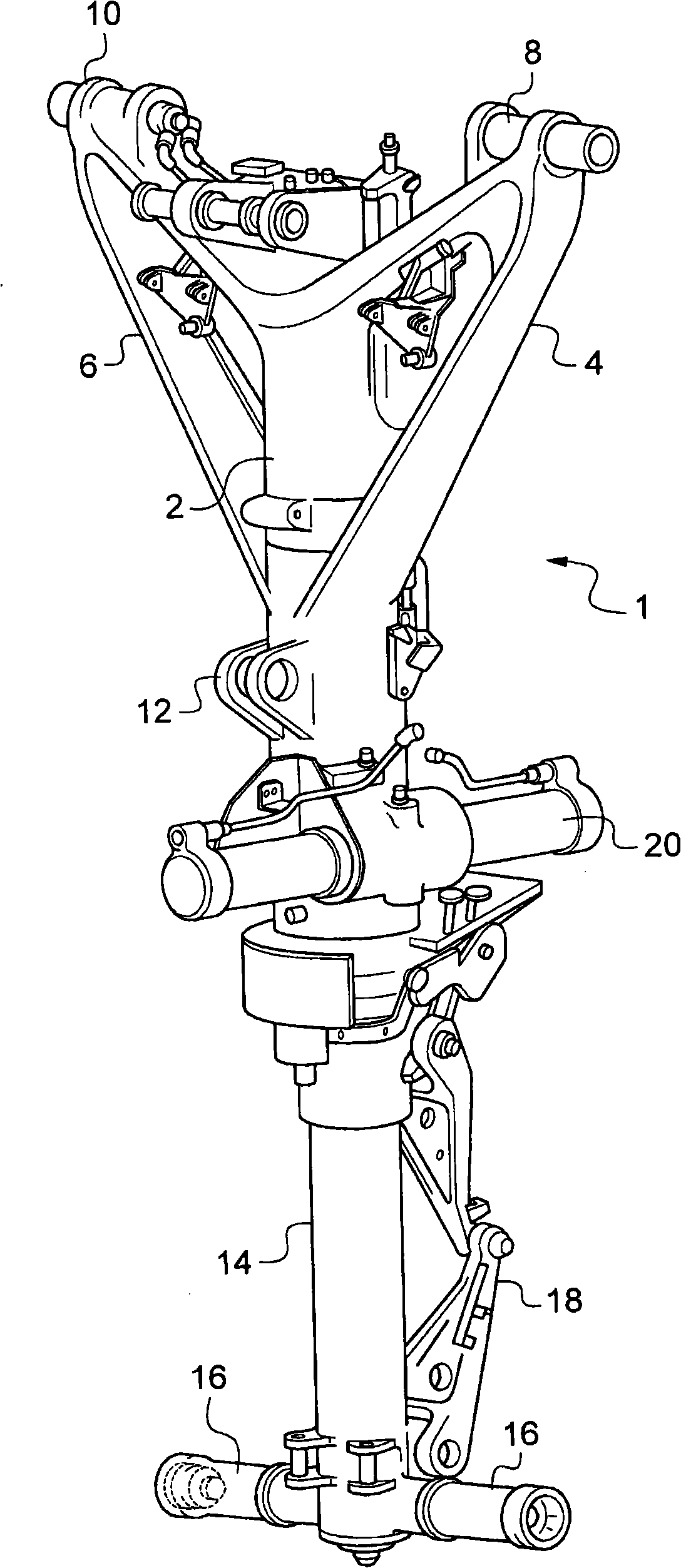

[0028] Figure 1 shows the nose wheel undercarriage of an aircraft comprising a strut 1 made of an aluminum alloy comprising a cylindrical part 2 with two side arms 4, 6 terminating in At the top of the reels 8, 9, these reels receive the articulation pins for connecting the struts to the aircraft. The strut 1 also includes fasteners 12 here in the form of two lugs forming forks (not shown) for receiving the strut in order to stabilize the undercarriage in the extended position.

[0029] A rod 14 is mounted to slide vertically in the cylindrical portion 2 of the strut 1 . The bottom of the rod 14 carries an axle 16 which receives the wheels. The rod 14 is connected by a torque link 18 to a steering member 20 fastened to the strut 1 , where the steering member includes a hydraulic br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com