Mild steel yielding and friction combined damper

A damper, mild steel technology, applied in building components, shockproof and other directions, can solve problems such as reducing energy consumption capacity, and achieve the effect of simple structure, uniform force and good energy consumption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

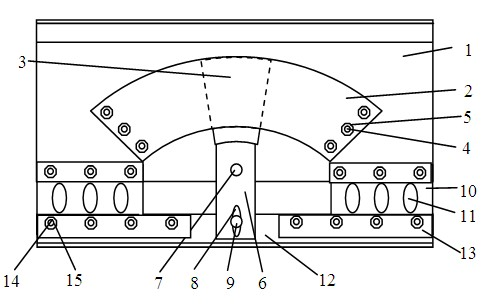

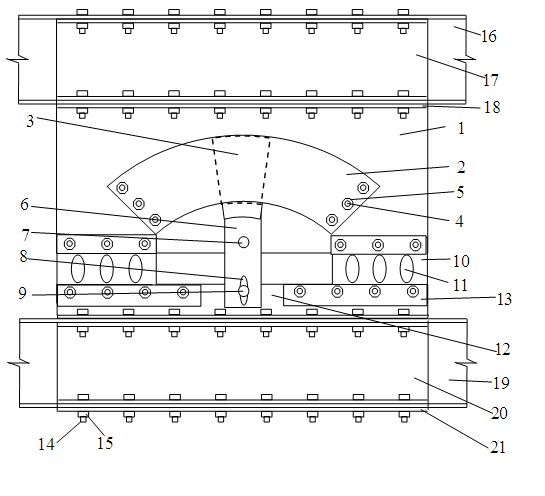

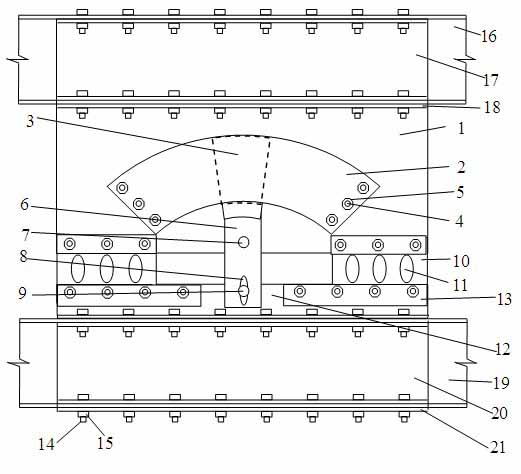

[0013] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

[0014] The mild steel yield and friction joint damper proposed by the present invention is as follows: Figure 1~Figure 2 shown. The whole device is mainly composed of T-shaped steel plate 1, single-sided friction plate 2, double-sided friction plate 3, friction force adjustment bolt 4, friction force adjustment nut 5, friction plate rotating rod 6, fixed rotating shaft 7, sliding hole 8, support connection and rotation Shaft 9, porous mild steel yield damper 10, mild steel yield damper with oval hole 11, support connecting plate 12, mild steel installation backing plate 13, bolt 14, nut 15, beam 16, beam reinforcement channel steel 17, pad Plate 18, herringbone support top 19, herringbone support top reinforced channel steel 20 and herringbone support will form strong backing plate 21 etc.

[0015] Cut two steel plates, we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com