Splash Liquid Density Tester

A density tester and liquid technology, which is applied in the field of measurement systems, can solve the problems of poor test time accuracy, long spray distance, and inability to accurately control the flow of liquid, and achieve the effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

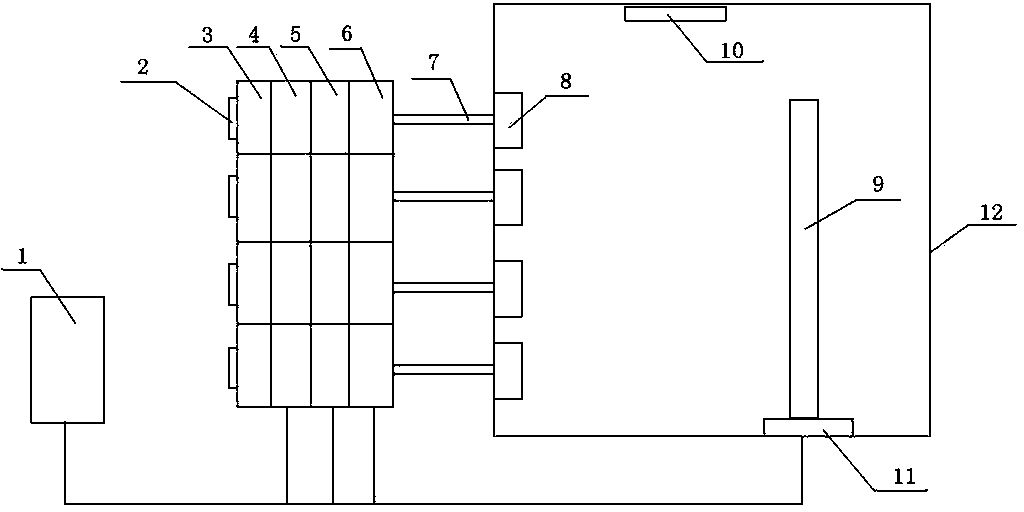

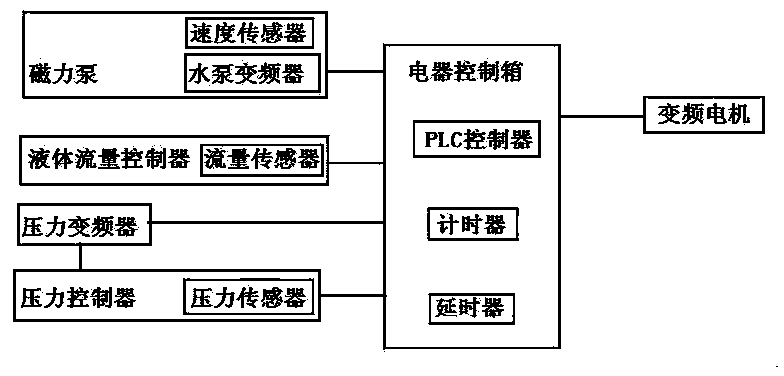

[0020] Such as figure 1 , figure 2 The splash liquid density tester shown includes: electrical control box 1, liquid adding cup 2, magnetic pump 3, pressure converter 4, liquid flow controller 5, pressure controller 6, conduit 7, liquid mist Spout 8, test model 9, test box cleaner 10, turntable 11, motor and outer cover 12; The described electrical control box 1 is provided with PLC controller, delayer and timer; Described magnetic pump 3 is provided with speed sensor and water pump inverter; the liquid flow controller 5 is provided with a flow sensor; the pressure controller 6 is provided with a pressure sensor.

[0021] The connections of the above components are as follows:

[0022] The liquid adding cup 2 is connected with the magnetic pump 3, the pressure converter 4, the liquid flow controller 5, and the pressure controller 6 successively from left to right; the pressure controller 6 is connected with one end of the conduit 7, and the other end of the conduit 7 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com