Electronic device shell and manufacturing method thereof

A technology of electronic devices and manufacturing methods, which is applied in the fields of electrical equipment casings/cabinets/drawers, decorative arts, electrical components, etc., and can solve the problems that the important functions of signs cannot be effectively exerted, are easily damaged by wear, and lack metal texture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

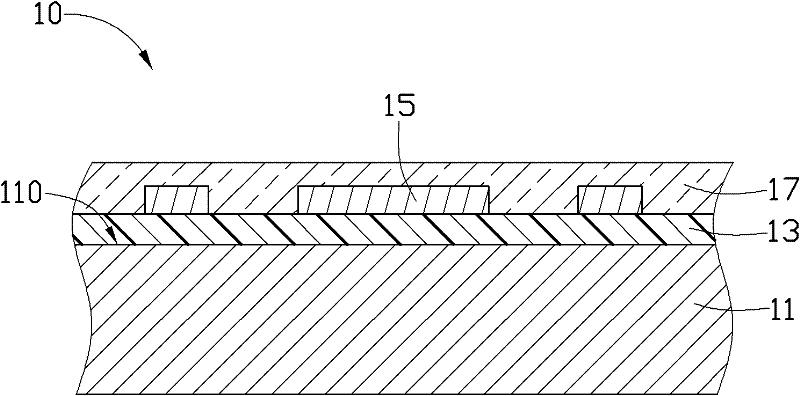

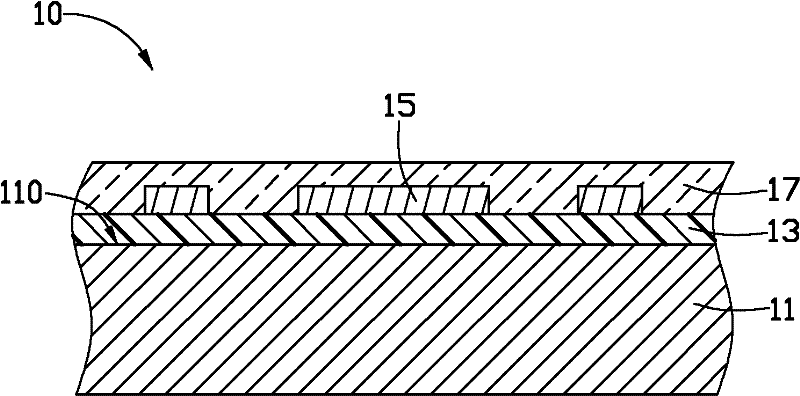

[0022] see figure 1 , the electronic device casing 10 of the preferred embodiment of the present invention includes a substrate 11 , a primer layer 13 , a metallic vacuum coating layer 15 and a transparent topcoat layer 17 . The vacuum coating layer 15 forms patterns on the housing 10 of the electronic device, such as logos, graphics and characters.

[0023] The base body 11 is made of plastic. The primer layer 13 is formed on the outer surface 110 of the substrate 11 . The primer layer 13 is used to increase the adhesion of the vacuum coating layer 15 . The thickness of the primer layer 13 is about 6-12 μm.

[0024] The vacuum coating layer 15 is formed on the primer layer 13 . In order not to affect the radio frequency transmitting and receiving functions of the electronic device using the electronic device case 10 , the vacuum coating layer 15 can be a non-conductive discontinuous coating layer with a metallic appearance. Preferably, the color of the vacuum coating lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com