PVC composite material based on self-drying water-based aluminum powder coating as well as preparation method and application thereof

A PVC material, self-drying technology, applied in the field of composite materials, can solve the problems that cannot be cleaned with water or other detergents, reduce the use time of the screen, and the polarization contrast is easy to weaken, etc., to achieve convenient packaging, transportation and installation, and good stretching effect , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

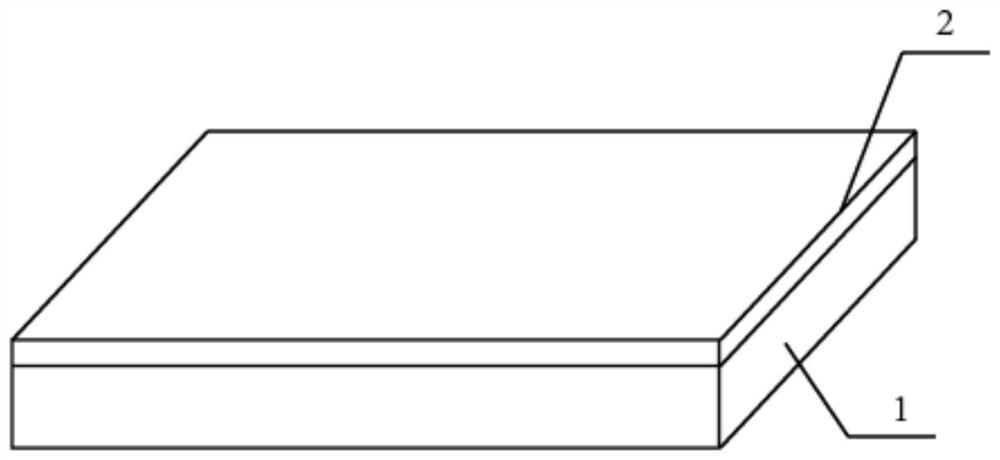

Image

Examples

Embodiment

[0021] The preparation method of PVC composite material based on self-drying water-based aluminum powder coating is as follows: adding water-based additives into water, adding water-based aluminum powder after stirring, adding water-based resin under stirring, and stirring to obtain self-drying water-based aluminum powder coating; The self-drying water-based aluminum powder coating is routinely coated on the surface of the PVC material to obtain a PVC composite material based on the self-drying water-based aluminum powder coating; after conventional natural drying or heating drying, a screen is obtained. Specifically, the above-mentioned water-based leveling agent, water-based anti-settling agent, and water-based wax slurry were added to water at a stirring rate of 1000 rpm, stirred for 15 minutes, and then added with a water-based defoamer and water-based dispersant, and stirred at a stirring speed of 1200 rpm for 5 minutes, Then add water-based aluminum powder, stir at 800 rp...

Embodiment 1

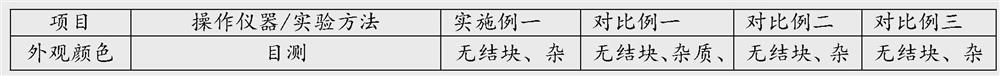

[0026] In Example 1, Comparative Example 2 and Comparative Example 3, the water-based resin is composed of water-based anionic aliphatic polyurethane SP-3106, water-based polycarbon polyurethane PU3461, water-based acrylic resin Crysol 6319, water-based alcohol with a weight ratio of 75:10:5:10. Acid resin 6070 composition; in Comparative Example 1, the water-based resin is water-based anionic aliphatic polyurethane SP-3106. In Example 1, Comparative Example 1 and Comparative Example 3, the water-based aluminum powder is composed of large aluminum powder and small aluminum powder, wherein the particle size D50 of the large aluminum powder is 25-35 microns, and the particle size D50 of the small aluminum powder is 8- 15 microns, the mass percentage of large aluminum powder is 35%, and the rest is small aluminum powder; in Comparative Example 2, the particle size D50 of the water-based aluminum powder is all 8-15 microns.

[0027] In the examples and comparative examples, the wa...

Embodiment 2

[0036] The water-based resin is composed of water-based anionic aliphatic polyurethane SP-3106, water-based polycarbonate polyurethane PU3461, water-based acrylic resin Crysol 6319, and water-based alkyd resin 6070 with a weight ratio of 75:10:5:10; the water-based aluminum powder is composed of large aluminum powder, It is composed of small aluminum powder, wherein the particle size D50 of the large aluminum powder is 25-35 microns, the particle size D50 of the small aluminum powder is 8-15 microns, the mass percentage of the large aluminum powder is 35%, and the rest is the small aluminum powder; water dispersion The wetting and leveling agent is BYK-346 and Tego 270 with a weight ratio of 1:1; the water-based defoamer is Tego810 and DAPRO DF 677 with a weight ratio of 1:1; the water-based anti-settling agent is AQ-633E ; Water-based wax slurry is LUBA-print 725.

[0037] In the weight parts of Example 1, the water-based resin was adjusted to 58 parts, and the water-based al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com