Dispersion of phytosterols

一种植物甾醇、分散体的技术,应用在食物科学、药物组合、有机活性成分等方向,能够解决产品低稳定性、产品不稳定、均质机阀磨损等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Stability of phytosterol dispersions prepared according to Test No. 5 of Example 1 of US Patent Application 20040029844.

[0083] 250g phytosterols, 25g sucrose stearate (Sisterna SP50) and 17.5g sorbitan lauroyl ester (Span 20) were mixed together at 135°C. The molten mixture was added to 5000 g of water kept at 80°C. The mixture was stirred at 7000 rpm for 15 minutes. 100 g of the dispersion formed were removed and allowed to cool to room temperature (sample 1.1). Furthermore, 500 g of the dispersion formed were fed into a homogenizer (APV-Gaulin, model MR-15) and homogenized in the next step at 480 bar. The homogeneous mixture was subsequently cooled to room temperature (sample 1.2).

[0084] The stability of both samples was determined according to Equation 1. The non-homogeneous mixture (sample 1.1) yielded a stability of 28.2%. A homogeneous mixture (sample 1.2) yielded a stability of 41.5%.

[0085] Both samples contained about 4.7% phytosterols by weight o...

Embodiment 2

[0087] Stability of phytosterol dispersions prepared according to Example 1 of US Patent Application 20070031570.

[0088] 500 g of water were heated to 49°C in a vessel. Then 33.3 g of soybean lecithin were added and stirred for 20 minutes. Next, 16.7 g of phytosterol and 50 g of maltodextrin were added to the container, and the resulting mixture was further stirred for another 20 minutes. Subsequently, the mixture was heated to 74 °C and placed in a high pressure 1 liter laboratory Parr reactor. The mixture was then heated to 152° C. for 1.5 minutes by adding live steam through a valve located in the reactor head. Next, the reactor was rapidly cooled to a mixture temperature of 79°C. When the reactor was opened, 200 g of the dispersion were removed and allowed to cool to room temperature (sample 2.1). Furthermore, at 79° C., 300 g of the dispersion were fed into a homogenizer (APV-Gaulin, type MR-15) and homogenized in two stages at 240 and 35 bar, respectively, and then...

Embodiment 3

[0092] Stability of Phytosterol Dispersions Prepared by the Process of the Invention Using the Emulsifiers of Examples 1 and 2.

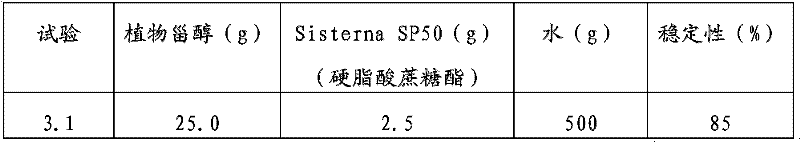

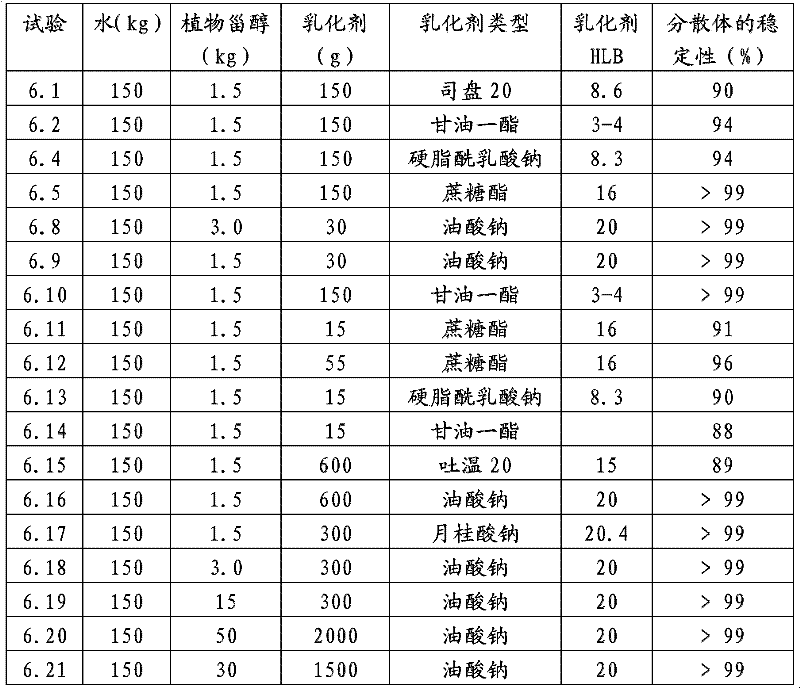

[0093] Test 3.1

[0094] A 1 liter Parr reactor (Parr Instrument Company, Moline, IL. USA) equipped with a turbo stirrer, nitrogen and vacuum lines, and controlled electric heating was charged with demineralized water, phytosterols, and one or more emulsifiers according to Table 4. . The closed reactor was evacuated over the course of 2 minutes, using 30 rpm stirring. Then, the stirrer speed was increased to 700 rpm and the contents of the reactor were heated to 160°C during 10 minutes. Next, the reactor was cooled to 25° C., and the internal pressure was equalized to atmospheric pressure using nitrogen. Samples were removed from the dispersion and their percent stability was determined.

[0095] Table 4

[0096]

[0097] Test 3.2

[0098] The previous experiment was repeated under the conditions of experiment 3.1, but varying the amount of...

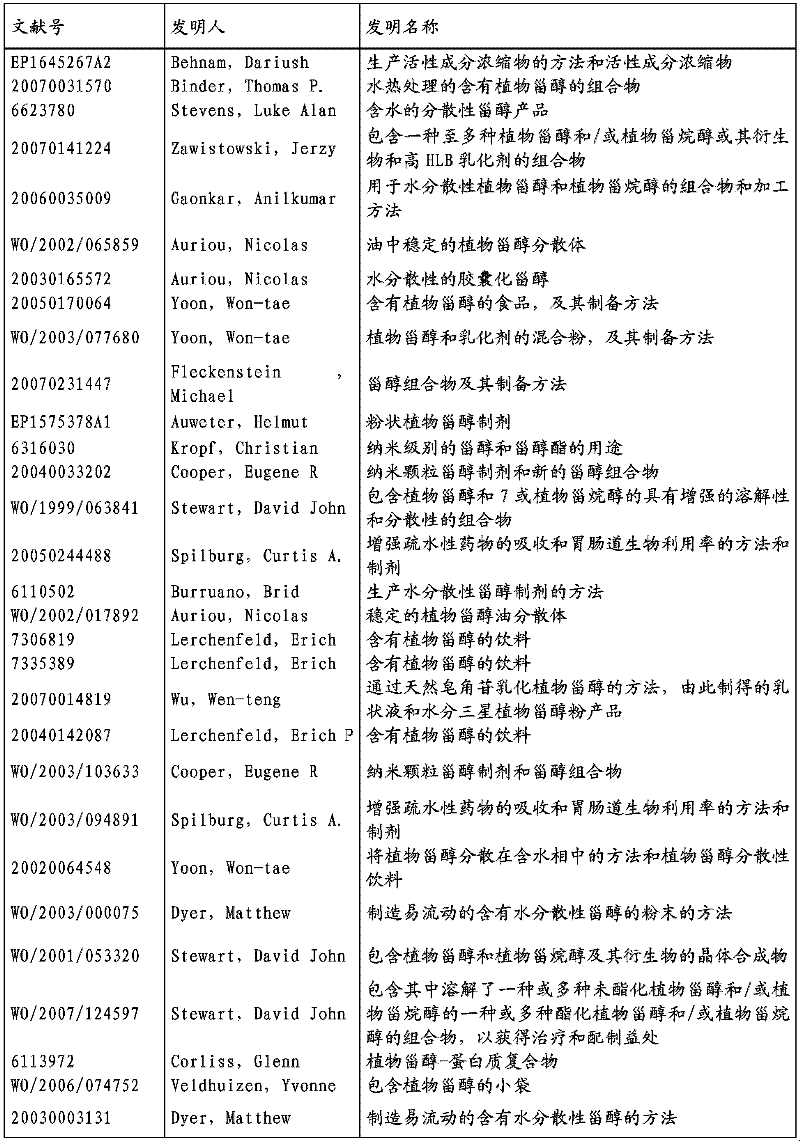

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com