Flexible, abrasion resistant textile sleeve and method of construction thereof

A technology for sleeves and fabrics, applied in the direction of fabrics, woven fabrics, textiles and papermaking, etc., can solve the problems of rising costs and achieve the effect of low manufacturing costs and enhanced protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

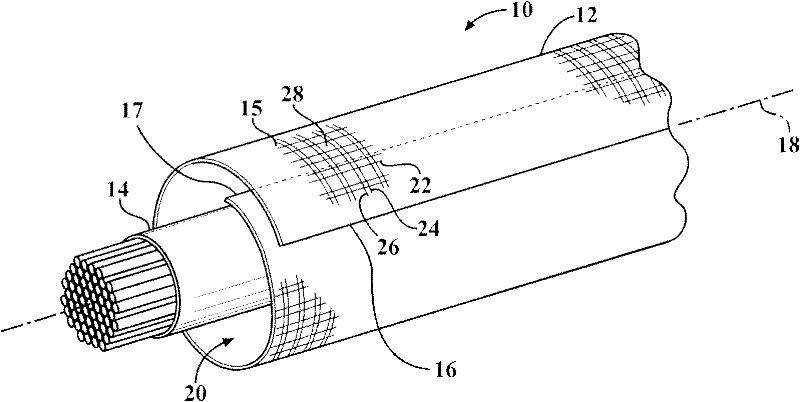

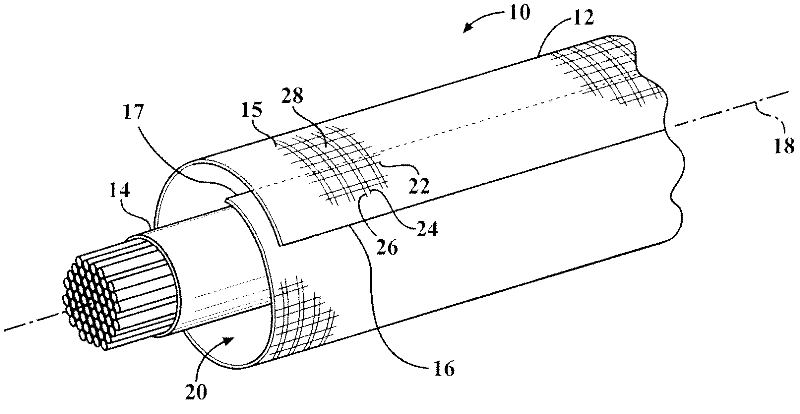

[0013] Referring more specifically to the drawings, FIG. 1 is a schematic illustration of a braided self-wrapping fabric sleeve, hereafter shown as sleeve 10 , constructed in accordance with one aspect of the present invention. The sleeve 10 has an elongated wall 12 for guiding and protecting the self-wrapping of an elongated element such as an electrical wire or harness 14, for example to protect the elongated element from wear and from the ingress of contaminants, debris, etc. . The elongated wall 12 has opposing edges 16, 17 extending generally parallel to the central longitudinal axis 18, wherein the edges 16, 17 are preferably deflected to overlap each other to wrap the elongated member 14 in a "cigarette wrapped" fashion. It is completely enclosed in the central cavity 20 of the sleeve. The cavity 20 can extend the entire length of the longitudinal axis 18, so that the elongated element 14 can be easily placed radially within the cavity 20 and, conversely, can be easily...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap