Combine harvester

A technology of combine harvester and car body, which is applied in the direction of harvester, cutter, chassis of agricultural machinery, etc., can solve the problem that the place where grain bags are placed is narrow, and multiple grain bags or large-capacity grain bags cannot be loaded. Operation efficiency reduction and other problems, to achieve the effect of improving efficiency, reducing the frequency of interrupting harvesting operations, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described based on the drawings.

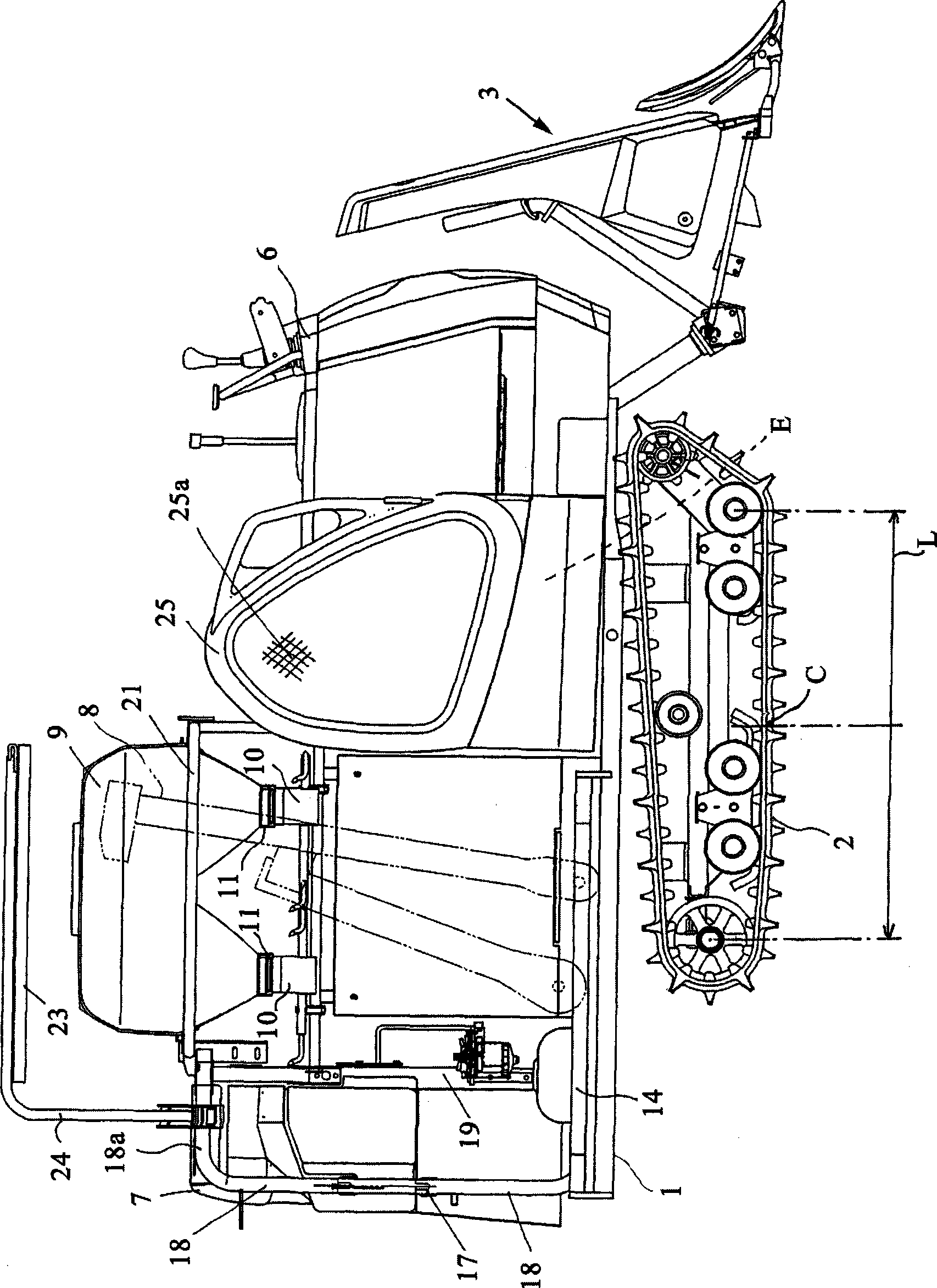

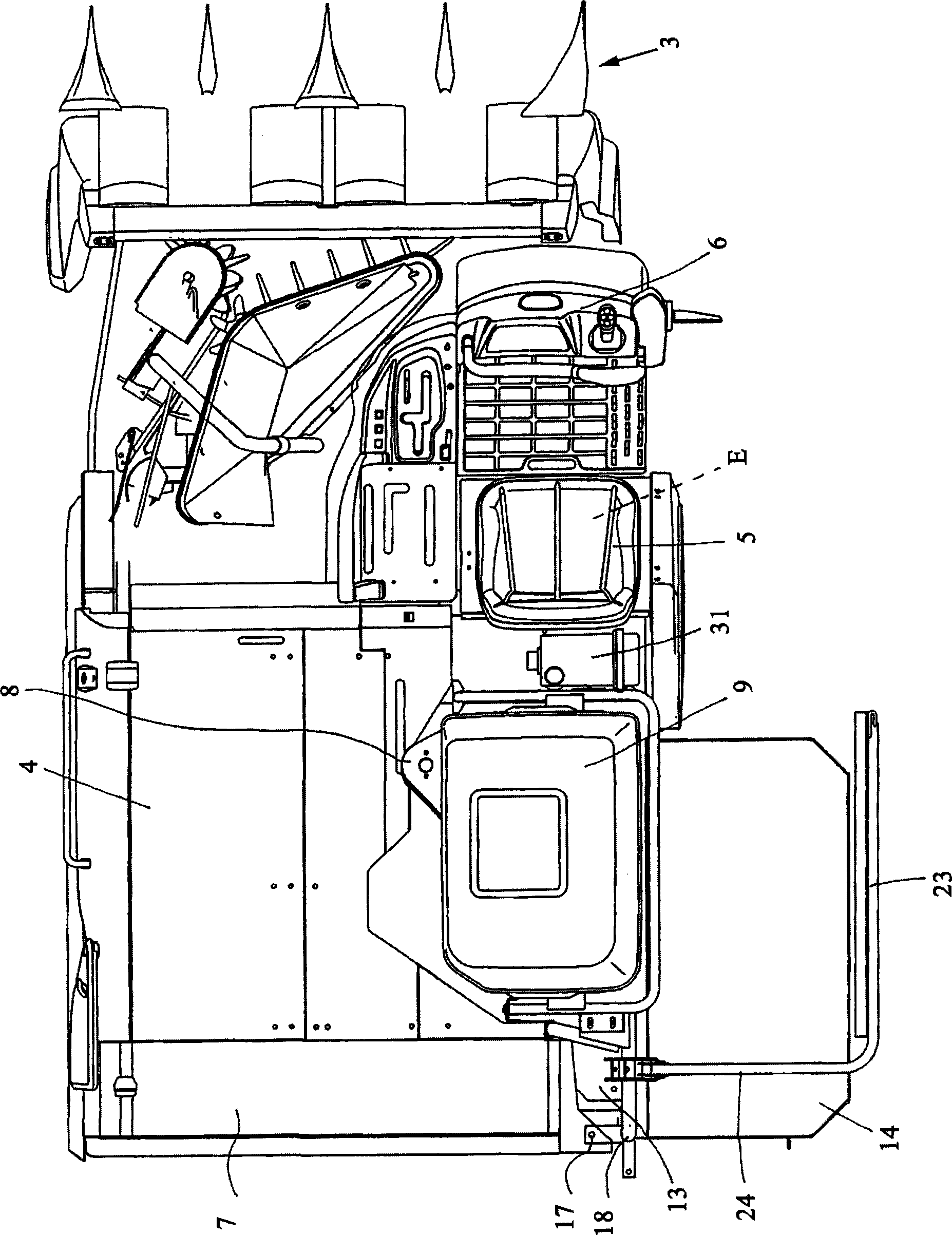

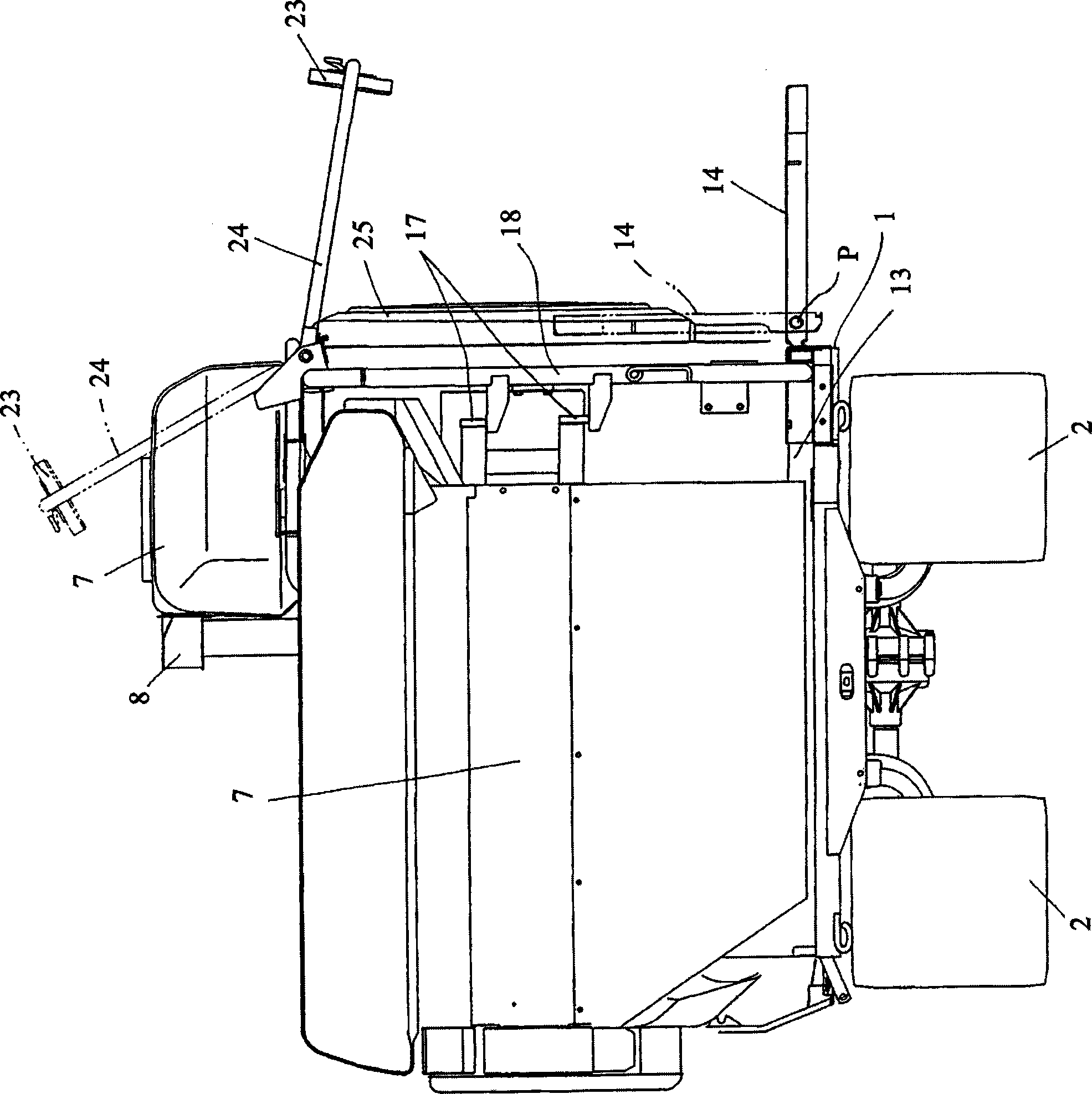

[0041] Such as figure 1 , figure 2 As shown, a pair of crawler-type traveling devices 2 and 2 are provided at the bottom of the traveling vehicle body 1, a reaping device 3 is arranged at the front side of the traveling vehicle body 1, and a threshing device 4 is mounted on the rear portion of the traveling vehicle body 1. The rear portion of the threshing device 4 is equipped with a discharge rice straw cutting device 7 that cuts the discharged rice straw after threshing. The grains supplied by the grain device 8 are temporarily stored in the hopper 9 . Moreover, the operation operation part comprised from the operator's seat 5, the operation box 6, etc. is provided between the harvesting apparatus 3 and the hopper 9, and the engine E is mounted under the operator's seat 5. As shown in FIG.

[0042] The lower portion of the hopper 9 is formed in a funnel shape, and a discharge tube 10 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com